Prusa Research’s late-2020 announcement of the new Original Prusa i3 MK3S+ was, all things considered, an unremarkable note capping an utterly remarkable year.

Detailed in a November blog update that charts two new printers, company news, Black Friday sales, and a glimpse at the future, the main takeaway for the new Original Prusa i3 MK3S+ is that it is not a performance upgrade. Rather, the new machine is the company ironing out fringe cases of its older mesh bed leveling probe underperforming.

You could be forgiven for wondering why they even bothered to give it a new name. It’s probably definitely nothing to do with the timing of the announcement, days before Black Friday, and the company’s most generous discounts yet. No siree.

The Original Prusa i3 MK3S+ is the latest iteration of Prusa Research’s original fused deposition modeling (FDM) machine. Starting at $749 (for the build-it-yourself kit), you get a 250 x 210 x 210 mm build volume, a magnetic, removable, PEI-coated spring steel print bed, Bondtech dual gear extrusion system, custom E3D V6 hot end, filament out detection, and enough smarts to make you wonder how half of it is even possible.

Fundamentally, it is the i3 MK3S you may know already, with a new bed leveling probe and minor design tweaks to improve things under the hood.

We had planned to do a fresh re-review of the MK3S for 2021, given the years that have passed since its launch. So, the timing of the MK3S+ couldn’t have been better. New name, not so new machine. How does it hold up in 2021?

Let’s find out.

Verdict

Pros

- Excellent print quality

- Foolproof (setup & in use)

- Smart, thoughtful touches throughout

Cons

- Selecting print jobs is laggy

- Not very quiet

- Pricey

Prusa Research’s latest is still a superior desktop 3D printing experience – attention to detail and technical finesse are its defining characteristics. Using the company’s filaments and filament profiles with the MK3S+ is magnificently foolproof, and the print quality from default quality profiles is invariably impressive.

With that said, experiencing it alongside the dizzying array of printing experiences available today highlights some of the ways that the MK3S+ feels a little dated. This is most noticeable when compared to some of the whizzy-quick touchscreen interfaces some printers now carry, and that loading print jobs from the SD card can hang and lag – there is, fleetingly, the sense that it’s running near the limits of some of its hardware.

Ultimately though, the Original Prusa i3 MK3S+ remains our go-to desktop 3D printer as the MK3S before it. Operating within the bounds of Prusa Research’s slicer and materials, if you can think it, it’s going to be pretty easy to print it. And even playing outside of the company’s ecosystem of materials and settings, we trust this printer to do it better and with less effort on our part than the others.

The Tech

A progeny of RepRap – an open, collaborative project to develop 3D printers capable of making more 3D printers (Replicating Rapid-prototyper) – the Original Prusa i3 MK3S+ is the latest in a long line stemming from Josef Prusa’s early contributions to the project. We’re several iterations later now, and a 600+ strong workforce in an enormous nine-story factory are two marked differences between the earliest basement-built Original Prusa printers and today’s MK3S+.

As with all past Original Prusa machines, the new i3 MK3S+ is open source, a principle the company diligently sticks to with all board diagrams, parts lists, designs, and code online for all to freely access. This marks Prusa Research apart a little as one of a few open source trailblazers in 3D printing. The RepRap project was founded on this community-driven design and iteration, and users of the machine today still feed fixes and improvements back to the company.

Despite the easily-copied source material resulting in clones undercutting the genuine article, Prusa Research thrives. Some 9,000+ printers shipped every month in 2020, even with a global pandemic disrupting supply chains and the company’s pivot to produce emergency PPE.

What’s New

The new printer is, mostly, the same as the MK3S it replaces. Nothing major about the design, features, abilities, UI, complimentary Haribo, or experience using it has changed.

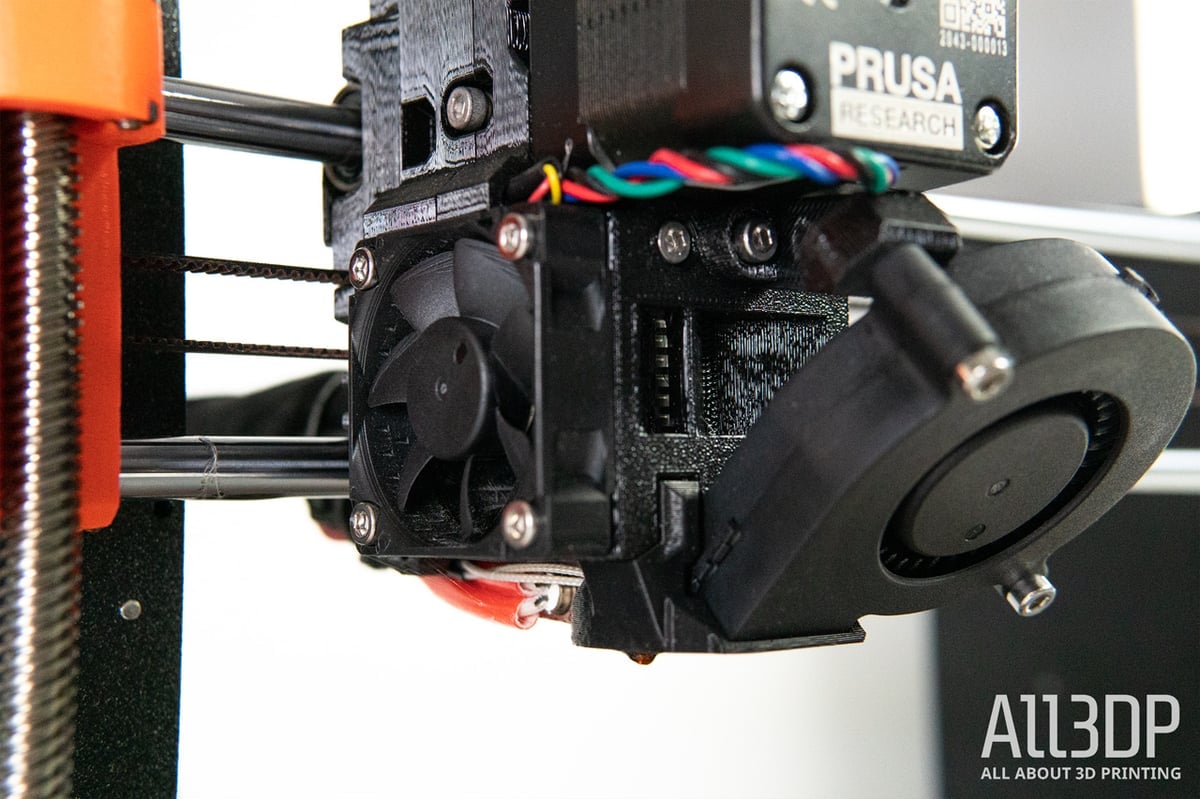

Headlining the few things that have changed is the new SuperPINDA bed leveling probe, alongside small design nips and tucks to the X- and Y- axes, how the print head handles flexible filaments, and the print-cooling blower fan mount, among others.

Options

The Original Prusa i3 MK3S+ is available either as a kit or factory assembled. Going hands-on and assembling the kit yourself keeps the price of the printer down at $749.

Those just getting acquainted with 3D printing could do a lot worse than the kit version of the printer, which typically gives an excellent, easy-to-follow introduction to the inner workings of a filament 3D printer.

Alternatively, Prusa Research offers a fully assembled machine that comes ready-to-run once you’ve snipped away the zip-ties that secure everything during transit. This convenience comes at a price, though, with the assembled printer tickling a grand at $999.

Our review is based on a factory assembled MK3S+, shipped with the typical spool of third-party-made, Prusa-approved PLA, plus requested samples of PVB – a new Prusa Research-developed alternative to PLA – and the company’s also-new tough PC filaments.

Also in the box is the typical assortment of Prusa Research goodies, including the tools to maintain the printer, spare nuts and bolts, stickers, candy, plus directions for printing and assembling an almost-entirely 3D printable Land Rover that uses the aforementioned spares. A nice gesture, layered with the kind of attention to detail prevalent all over the printer and ecosystem the company has built for it.

Even the assembled version of the printer ships with a novella about the 3D printer, its myriad features, menu options, 3D printing in general – more or less all you’d need to get started if you had no connection to the internet to look stuff up for yourself. It’s the polar opposite of the kind of experience you get with even the most popular budget alternatives, which thrive on communities coalescing behind their innate affordability – Prusa Research gives you all the knowledge itself and has the community.

RepRap Looks

The MK3S+’s looks have changed very little since earlier i3 model printers. The stamped steel plate for the frame is derived from the original i3’s simplicity (easy to fabricate from wood using a CNC router) but has carried through all generations to this new machine, forming the printer’s signature look, along with another hallmark of RepRap 3D printers – visible, functional 3D printed components.

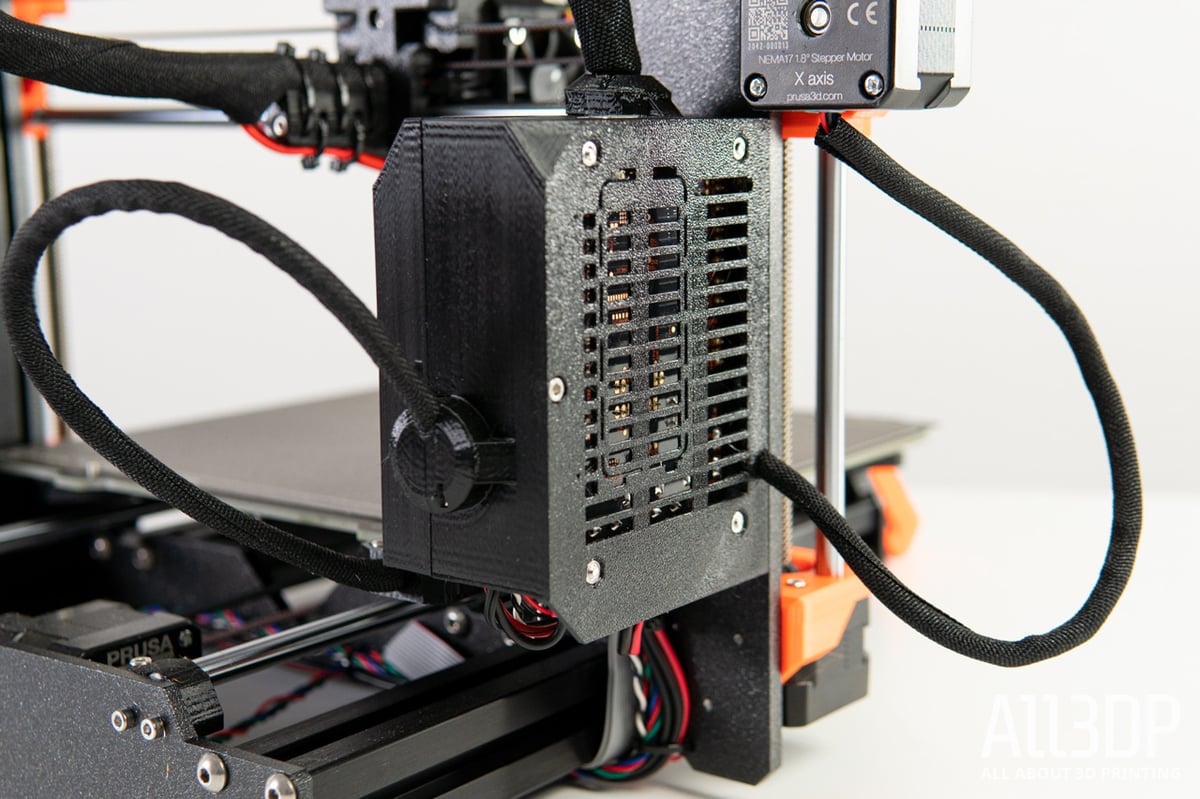

The MK3S+ is no exception in its visible use of printed parts, present here in the “Prusa Orange” display cover, rotary encoder, pulleys, electronics enclosure, and a significant portion of the print head assembly. All printed on the company’s giant farm of custom i3 machines – Prusa Research itself may be its biggest customer.

This would go a long way to explaining the baffling sophistication of the MK3S+. Issues with the printer would cost time and money in the company’s print farm, so no one is more intimately aware of or riding on the printers’ durability than its maker. This flies in the face of more efficient production methods such as injection molding, which would be suited to the repeated production of a limited number of parts. On the flip side, the company gains an enviable insight into its own product simply through having to use it so much.

The Tech

The Original Prusa i3 MK3S+ uses a custom E3D V6 hot end to do the business end of filament melting, with material coming by way of a dual gear filament feed from Bondtech – two household names in 3D printing that typically represent quality.

Heating to 300 ℃, the hot end can handle a wide variety of 1.75 mm filaments, ranging from your everyday materials such as PLA, PETG, and the noodliest of flexibles, to more demanding engineering plastics such as polycarbonate (PC) and nylon. Typically, the hotter you’re printing (as you typically will do for such materials), the more you’ll need to do to mitigate these materials’ tendency to warp off the build plate. You may want to consider building an enclosure. For all the confidence the MK3S+ gives you printing exotic filaments, the printer is not in control of the ambient temperature – print failures do happen.

The Prusa Research-made “MK52” heat bed – 24 V, same as the hot end, meaning speedy heating – is laced with neodymium magnets that will virtually snatch the spring steel build plates out of your hand when placing them down. It’s reassuring how firm they hold in place, but this action can be pretty violent. If you’re not careful, it can pinch your fingers.

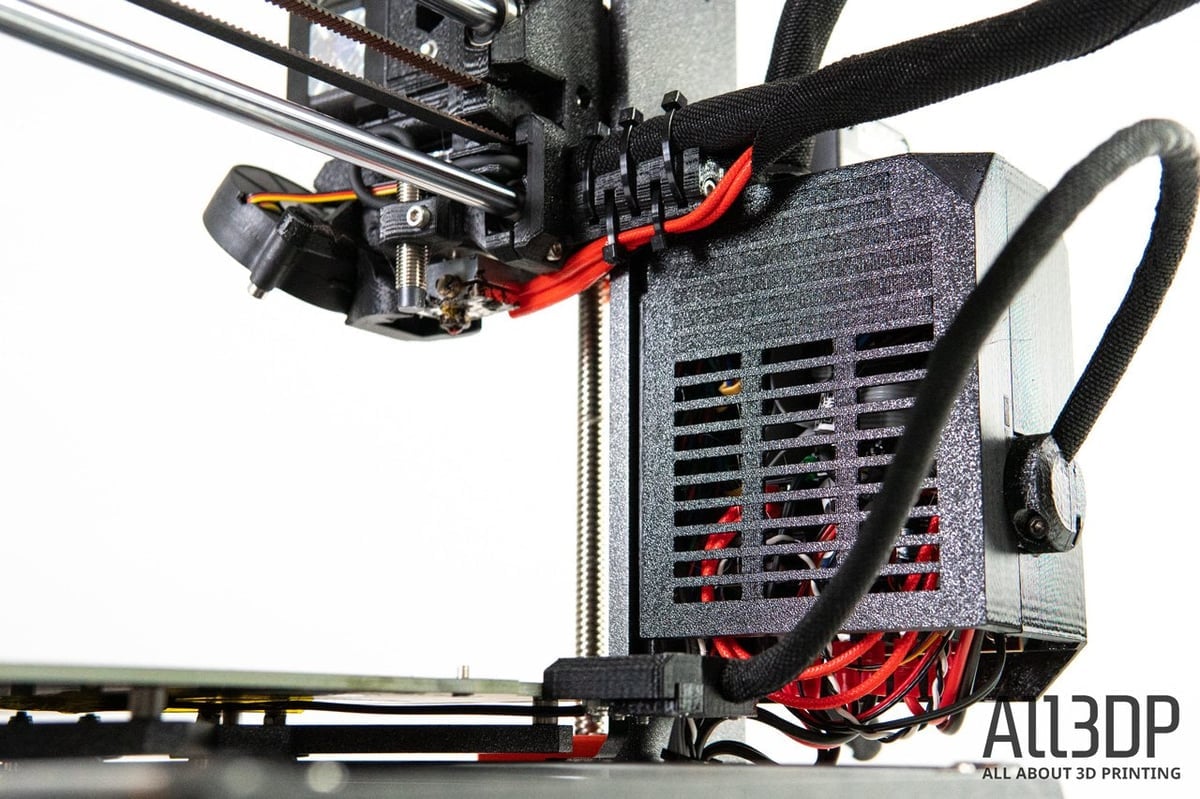

Keeping the G-code humming along in the background and coordinating this orange icon of a printer is the Prusa Research-developed, Ultimachine-made, 8-bit Einsy Rambo mainboard, featuring TMC2130 stepper motor drivers that make a number of the MK3S+’s more unnatural-seeming abilities possible. One is sensorless homing, which sees the MK3S+ fling its print head and bed in the direction of home and registering the zero at the point it meets physical resistance. (In other words, the frame of the printer.)

Similarly, you can engage the so-called “Stealth Mode,” whereby the MK3S+ hushes its stepper motors through electrical current manipulation that we won’t pretend to understand. In practice, we didn’t notice a huge difference in the noise level from the printer. This “stealth” comes at the expense of a slightly longer print (though not by much, we’ve noticed – a matter of minutes) and the disabling of crash detection, which is yet another fancy driver-enabled trick that, like the sensorless homing, detects resistance, but in this case pausing the print for you to remove the obstruction.

Overall, a large part of the Original Prusa i3 MK3S+’s abilities boils down to the board and stepper motor drivers it uses and Prusa Research’s ability to squeeze every measure of use out of their features with the memory available to them. The result is a 3D printer that has a lot of smarts.

Setting Up

A further layer of sophistication in the MK3S+ presents itself in the suite of diagnostics and self-checks the printer can do. Besides the initial calibration wizard that runs when you first boot the printer up, you can access a sub-menu of calibration tests that see the printer check the likes of its axes against one another, find the 9 points it uses to probe the bed for auto bed-leveling, calibrate its ability to reach and hold a temperature, and other useful but infrequently used tests.

We suspect most of them are there to verify user-assembled MK3S+ printers, ensuring that the build is to a good enough standard that the machine plays nicely with the optimized material and printer profiles in the PrusaSlicer. Very few other printers come to mind that offer this kind of self-diagnostic – usually machines costing thousands of dollars, not hundreds.

In day-to-day use of the machine, you’re more likely to use the first-layer calibration wizard than any of the others. Selecting this routine sets the printer laying down a single-layer pattern that zig-zags its way across the print bed, with you – fingers on the encoder – dialing the Z-offset up or down, bringing the nozzle closer to or further away from the bed. It’s a useful routine, one that ensures you waste fewer prints configuring your first layer before you start printing. It can be tricky to see what’s happening though, since the print bed draws towards you with the print head and print cooling blower obscuring your view of the live printing. It’s not unworkable, but surely there are better directions or patterns to print that offer a better view of your live adjustment.

You get more smarts in the i3 MK3S+ with print bed profiles. Since you can purchase different texture print beds that are of differing thicknesses, you can tell the printer which you’re using and it will save the configured Z-offset (set during the wizard or in-print using the “Tune” menu) to that specific print sheet.

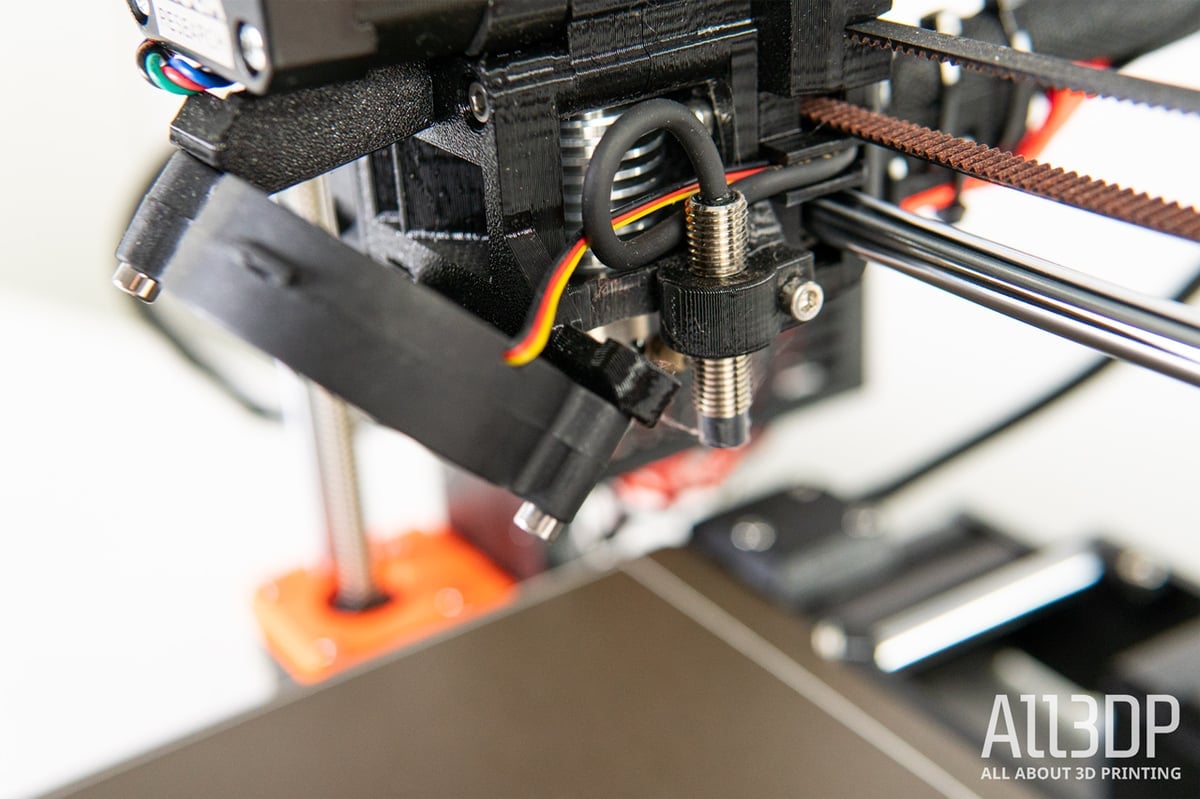

The printer runs its mesh bed leveling routine before every print, measuring the Z-heights of nine points on bed, taking these readings and adjusting its path when printing to ensure that the nozzle offset stays the perfect distance across the span of the print bed, no matter the deviances it may have. It’s here that the new SuperPINDA comes into play, riding shotgun alongside the nozzle and inductively detecting the print bed as the print head lowers to meet it. The new sensor is temperature independent and uses fewer, more durable components, cutting down on what Prusa claims was the main cause of problems with the past PINDA and MINDA mesh bed leveling sensors.

Behind the scenes, it’s our understanding that the Original Prusa MK3S+ accommodates some of its components’ unique characteristics. A primary example of this is the RPM of its many fans, which can vary from fan to fan. This more or less means that every MK3S+ acts differently to the next and adjusts the signals it sends to said components for reliable performance. Yet another example of the level of detail and attention the MK3S+ exhibits.

Also, we can think of few other manufacturers to put out firmware updates to its machines as often as Prusa Research. Rattling through the changelogs will make your head spin. Pessimists would argue that it shouldn’t need so many fixes, but we’d counter that with how many manufacturers a, even bother to fix the known issues (and quickly, at that), or b, also regularly add in new features? It’s a very short list.

Were you to compare a day-one MK3 to the MK3S+, you’d see a small gulf of differences. There’s certainly a noticeable difference in the machine’s abilities. And even back then, we found the MK3 to be the cream of the crop.

Printing and Usability

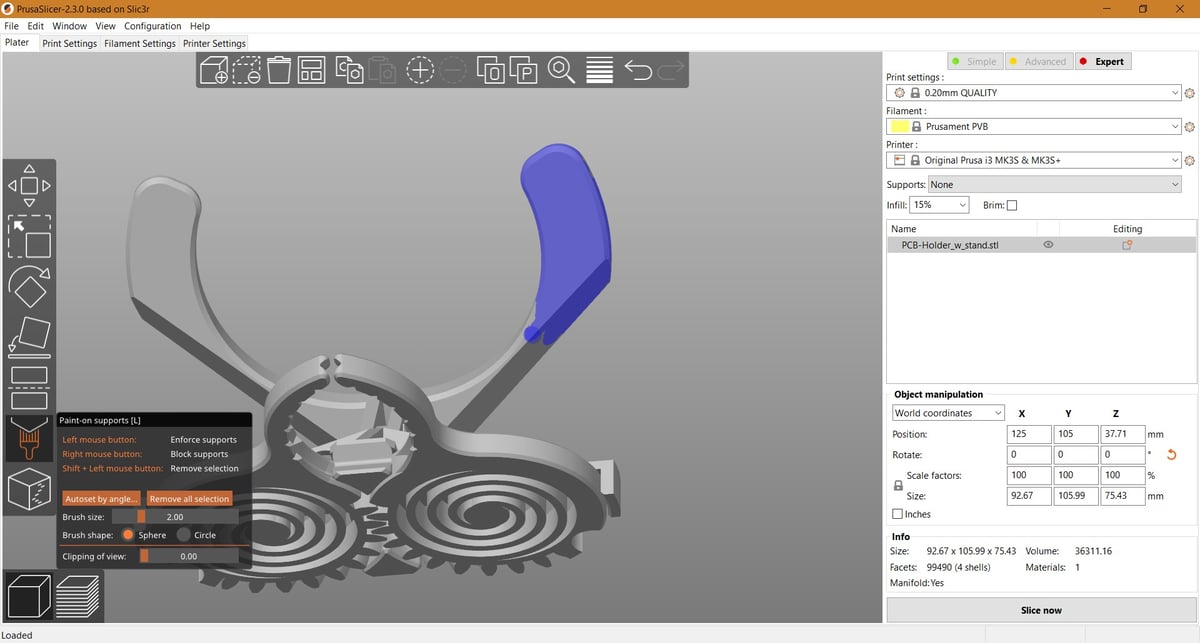

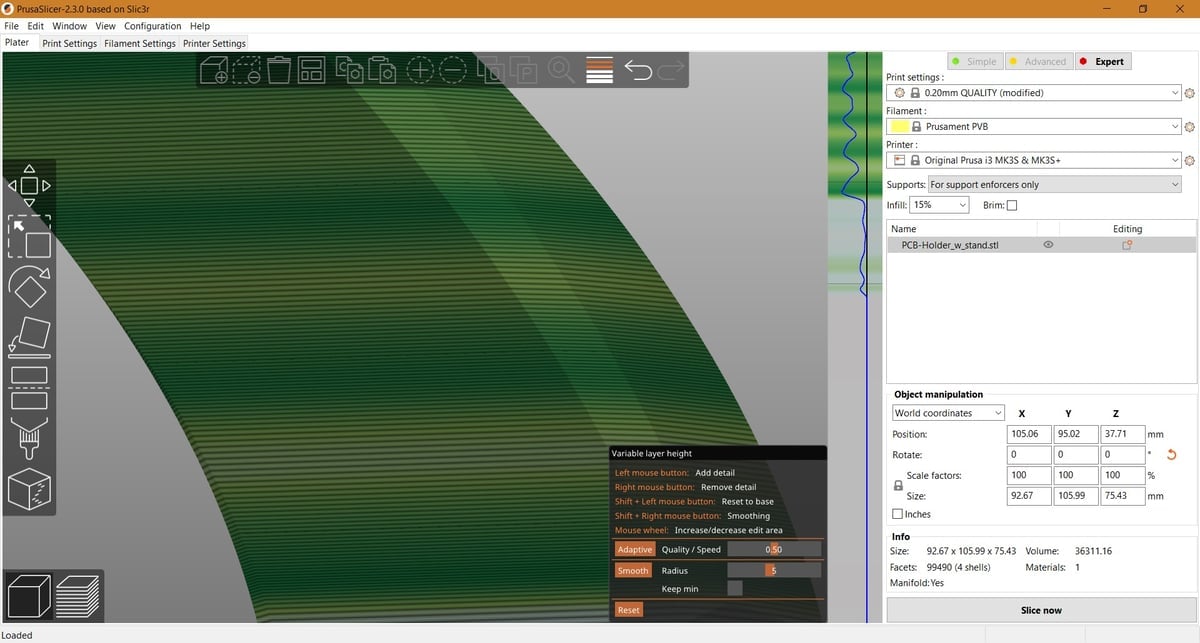

The Original Prusa MK3S+ plays nicest with Prusa Research’s in-house slicer, PrusaSlicer, itself based on the open-source Slic3r. In line with the printer, the slicer is also filled with smart, user-friendly features that seem designed to improve print quality without obfuscating things behind impenetrable menu structures and dense terminology.

The overall presentation of the program may seem a little overwhelming for newcomers; the combination of chunky icons mixing with the pure function of tabbed menus gives the impression that it’s stuck between two styles. Nevertheless, everything you need to configure your prints is at your fingertips. Throwing the slicer into “Simple” mode swipes the more advanced options for print preparation out of the way, letting you focus on the simple things like orientation, material, print quality, and speed (using preconfigured print profiles).

Cycling up through the “Advanced” and “Expert” modes gives you more control over the finer variables of print preparation, but throughout our time taxing the MK3S+ with the company’s own filaments, plus third party materials, we rarely found ourselves dipping into them except to adjust temperatures, add extra perimeters or to alternate infill layers. The default settings are usually pretty good.

Among the fancier tools available to you in the software are options to interrupt your print at specified layers to change filament colors (no option to change the temperature, though, so if you were to try changing materials, you’d need to use two with similar temperature profiles. Additionally, there are tools that take essential concepts of print preparation and make them completely accessible, such as “Paint-on Support” structures – using your computer’s cursor to draw where you’d like the slicer to place support structures on your model. No wrestling with angles or separate support enforcement blocks.

Likewise, the “Seam Painting” feature lets you choose exactly where the outer perimeters start and end, giving you greater control over the surface finish of your prints.

Object instancing, per-object settings, and customizable variable layer heights are but a few other features that give you an extraordinary level of control over your printing.

Further to all this, the slicer keeps track of the release of firmware updates, baking this knowledge into the files you port over to the printer. When there’s a more current firmware available, the printer will prompt you to consider updating it in a skippable pre-print message.

Data

From unboxing the MK3S+ to loading filament and slicing your model, you are bombarded with data.

Sitting on top of the documentation in the box is a ticker readout of your machine’s factory testing results (the most important part of which is the serial number). You nod thoughtfully before tossing it aside to dig into the printer. When slicing, you’re presented with a minute-by-minute breakdown (even seconds, in some cases) of exactly how long the printer spends doing each part of a print. Buy a spool of Prusament filament from the company and you can see the variance in diameter throughout the entire spool.

It’s an impressive flex of information to share on Prusa Research’s part, but realistically we see little tangible value for it. You wouldn’t not buy other machines or filament because of the lack of this information. It’s fleeting comfort, but ultimately just noise.

Printing

As you might have gathered, we use a lot of 3D printers here at All3DP. And while we strive to give every printer we test a fair shout, it’s usually with a sigh of relief when we get to return to printing with the MK3S. The MK3S+ is no different.

Use one of the provided material print profiles to prepare your print and it-just-works. Use different third-party materials, and the generic profiles are, minus temperature adjustments, a decent starting point for you to customize.

Selecting prints on the MK3S+ can be a bit of a drag though, and this is perhaps our one main criticism – this thing hangs and lags. You can whip back and forth around the configuration menus at speed, twirling the 3D printed control dial as you go, but once you access an SD card loaded with prints, it stutters into molasses. The typical brevity the dial gives is gone, and we often found ourselves overshooting the file we wanted to print and had to bounce back and forth.

The colorful displays and on-brand iconography of the company’s other machines, the Original Prusa Mini+ and Original Prusa SL1, give a glimpse of the MK-series’ future, we should imagine. Just not for this go-around.

Whenever something has gone wrong with our prints, it’s typically been because we’ve done something wrong – improper settings, forgetting to change filament, and so on. It’s easy to paint a picture of Prusa Research’s machines being infallible wonder machines, but they are still just tools. Great tools. But tools can be misused. The MK3S+ employs a lot of checks to ensure the machine does the best job it can, but it can’t account for human error. It’s still very easy to mess things up and damage the printer – case in point, we absent-mindedly printed PC onto the smooth PEI sheet with no glue as an interface layer – ironically the glue is to prevent the PC from bonding to the PEI. We were in the flow of things, didn’t give it a second thought to flip to the clean side of the plate. A big no-no and the sheet is ruined.

Not a mark against the printer, per se, but a cautionary note that you can’t switch your brain off with the printers that do most of the work for you. The software and hardware’s abilities to nudge your slice and create the conditions for great prints are easily undone by inattentiveness.

Is It Worth It?

There are no real surprises to be found with the Original Prusa i3 MK3S+. Much like the MK3S that it replaces, the MK3S+ is still an excellent 3D printer to run day in, day out, whether you’re using the company’s house materials or third-party filaments. It comfortably operates at higher temperatures for tougher materials such as nylon and PC, provided you can manage the environment around the printer.

Prusa Research’s transparency about the development, features, failures, plus the growing ecosystem to complement the machine – most notably in the last year or two with the addition of a 3D model repository, mapped out userbase, plus Prusament filament production – make the MK3S+ one of the most complete desktop 3D printers you can own today.

The argument could be made that it’s pretty expensive compared to the popular competition. But, where those machines revel in their simplicity, the Original Prusa MK3S+ carries itself on sophistication that doesn’t come at the expense of usability.

The slowdown when queueing up a print is a minor frustration among the ocean of positives we can say about the MK3S+ – it’s a highly capable workhorse, just as the MK3S was. We still like it a lot. Most of you likely will, too.

Features

Rather than wholesale changes, there are modest improvements on the Original Prusa i3 MK3S+ over the MK3S.

Same Same

This means you get the same 250 x 210 x 210 mm build volume (which skews a little small by today’s standards), stamped metal frame, 8-bit Einsy Rambo mainboard, fully-featured Trinamic drivers for silent operation and sensorless homing, SD card operation with an LCD screen and control via rotary encoder.

You still have power panic print recovery, the quick mesh-bed leveling, automatic crash detection, somewhat silencing “stealth” print mode, and everything else that made the MK3S our long-running top recommendation for desktop 3D printing.

As is pretty obvious from the name, the MK3S+ is, fundamentally, still the MK3S.

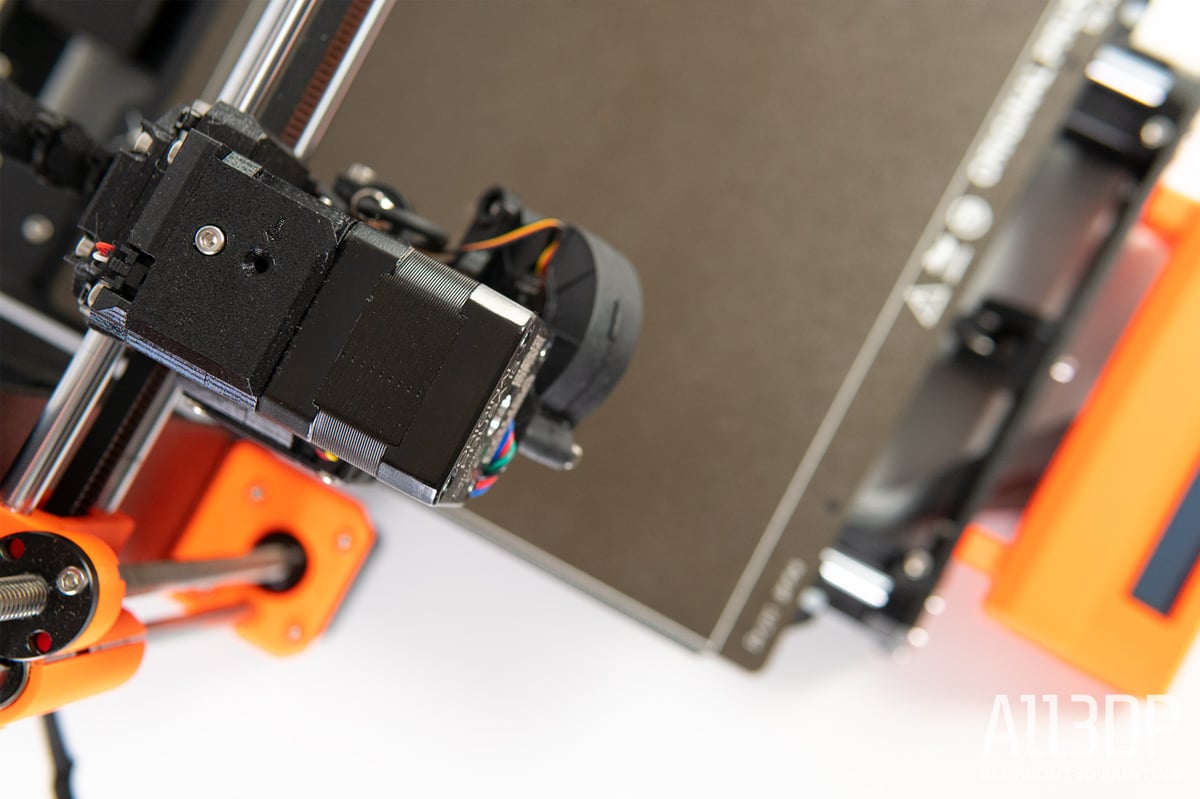

The new stuff can primarily be seen in an all-new SuperPINDA probe and minor changes to both the X- and Y- axes, as well as the extruder.

SuperPINDA Bed Leveling Probe

An evolution of the PINDA 2 inductive bed leveling probe found on the MK3S, this new version of the probe does away with its inbuilt thermistor (used previously as a measure to offset against the probe’s thermal drift), and increases repeatability and reliability, the company claims.

There’s not thought to be any noticeable performance improvement from the SuperPINDA from print to print, but long-term gains through the use of better quality components for durability.

X- and Y- Axis Improvements

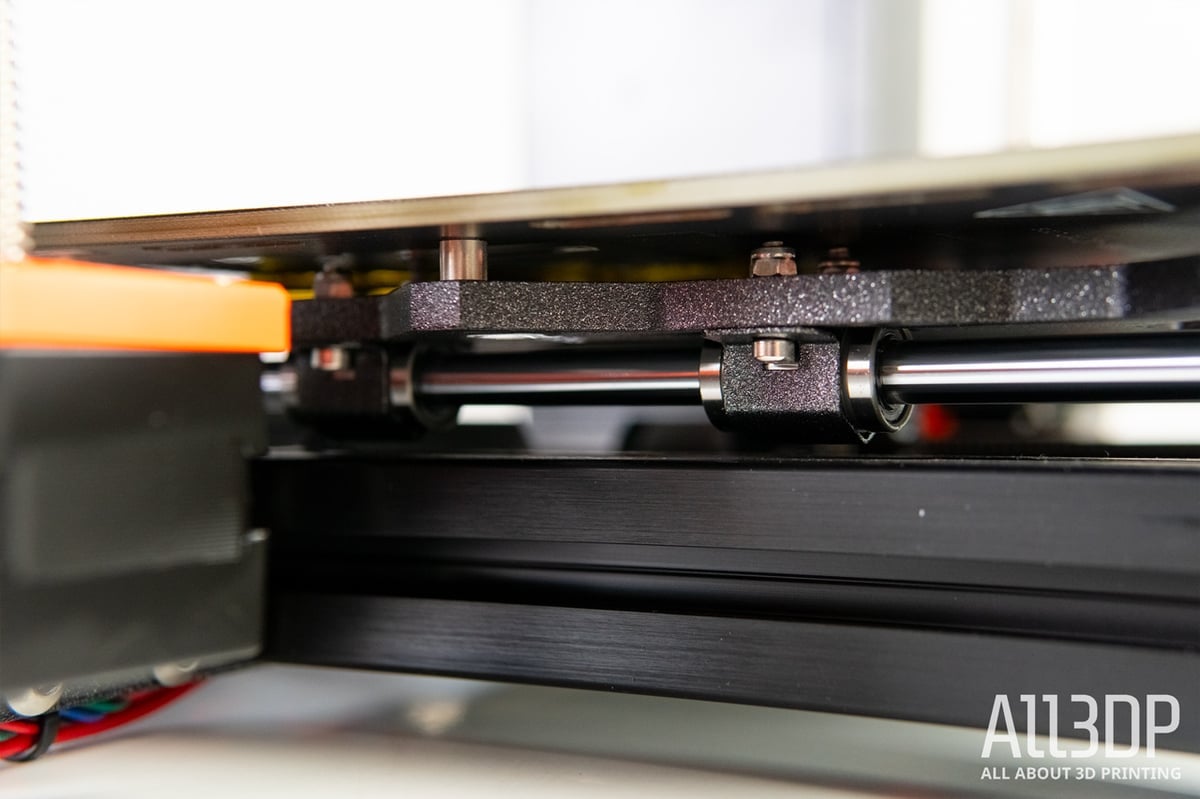

Minor design changes to the X- and Y- axes come to the MK3S+ as improvements to the printer’s buildability.

The smooth rods for the Y-axis carriage are no longer secured using zip-ties, using plastic holders instead. The carriage’s bearings are also secured differently now, with simple screw-in metal clips as found on the Prusa Mini instead of the U-bolts used on the MK3S.

Extruder Changes

The extruder housing also sees a slight redesign, with a tighter filament path introduced to improve the printer’s ability to print flexible materials. Access to the extruder gearing is also said to be better thanks to the idler door being able to open wider than before.

The part cooling fan shroud attaches in two places now too, a measure detailed alongside mention of improvements to the heat resistance of extruder parts – handy, should you put the printer in an enclosure and go to town with high-temp materials such as PC.

Tech Specs

GENERAL SPECIFICATIONS

- Technology: Fused deposition modeling (FDM)

- Year: 2020

- Assembly: Assembled

- Mechanical arrangement: Cartesian XZ-head

- Manufacturer: Prusa Research

3D PRINTER PROPERTIES

- Build volume: 250 x 210 x 210 mm

- Feeder system: Direct drive

- Nozzle size: 0.4 mm

- Max. hot end temperature: 300 °C

- Max. heated bed temperature: 120 ℃

- Print bed material: Removable magnetic PEI spring steel sheet

- Frame: N/A

- Bed leveling: Automatic

- Connectivity: SD, USB Type-B

- Print recovery: Yes

- Filament sensor: Yes

- Camera: No

MATERIALS

- Filament diameter: 1.75 mm

- Third-party filament: Yes

- Filament materials: Up to nylon, polycarbonate

SOFTWARE

- Recommended slicers: PrusaSlicer

- Operating system: Windows, Mac, Linux

- File types: STL, OBJ, AMF, 3MF

DIMENSIONS AND WEIGHT

- Printer dimensions: 550 x 400 x 500 mm (without spool)

- Weight: 7 kg

Similar Machines

What could possible compare to the Original Prusa i3 MK3S+? As it happens, a couple of printers have some of the chutzpah to turn heads from Prusa Research’s flagship printer.

Original Prusa Mini+

Predictable, we know. The Original Prusa Mini+ is almost as capable as the larger MK3S+, albeit missing out on the full-frame i3 style in favor of a cantilever design with Bowden extrusion system. 180 x 180 x 180 mm build volume is not a huge step removed from the MK3S+, and best of all, it’s around half the price.

Creality CR-6 SE

A novel bed leveling system and generally great print quality out of the box help Creality’s kind-of-experimental Kickstarter-backed CR-6 SE stand out from the crowd. It’s not as cheap as Creality’s Ender 3 series machines, but in terms of feature set, it’s the closest this budget-focused company has come to touching the i3-series.

License: The text of "Original Prusa i3 MK3S+ Review: Best 3D Printer Under $1000" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.