Looking back at 2023 it could easily be described as a year of fewer-than-usual 3D printer launches, but it was perhaps a year of quality over quantity.

Some of the stand-out hardware innovations of this past year included the quartet of next-generation FDMs (Markforged’s FX10, Stratasys’ F3300, Aon3D’s Hylo, and MiniFactory’s Ignite) reflecting heightened automation and process control. There were impressive advancements in dental 3D printer offerings, including 3D Systems’ NextDent LCD1, Stratasys’ J3 DentaJet, Nexa3D’s XiP Pro, and Structo’s ST-01, satisfying practitioners’ need for production and speed.

In the metal laser powder bed fusion technology category, the battle of the lasers rose to unprecedented levels with BLT’s S800 12-laser set up and the new 25-laser Eplus3D EP-M1550.

Start-up 3D printer makers are noticeably few on our 2023 list, which is dominated by the established players, but there were strides among the leaders in the consumer market to break into the professional side: Elegoo launched its capable, large-format FDM, Prusa is poised to gain ground with its delta FDM, while Bambu Lab’s X1E aims to redefine the prosumer category.

No matter which technology you’re after it likely launched in 2023, with many of the machines below slated for commercial release in 2024 if they’re not available already.

Markforged's FX10 FDM

(Nov. 12, 2023) The second FDM 3D printer in Markforged‘s FX series (after the FX20) is the new FX10. It is also a continuous carbon fiber printer, but it’s smaller than the FX20 and larger than the X7. Markforged offers eight carbon fiber 3D printers, so what niche is the FX10 filling, you may ask.

According to what Markforged told All3DP at Formnext, the FX10 is the company’s factory line workhorse. In other words it’s meant to continuously churn our essential jigs and fixtures, tools, and spares for long periods of time with no manual intervention. It achieves this through nearly “a hundred” sensors and automation. There are print head-mounted optical sensors that can verify dimensional accuracy of parts as they print, other sensors to assess device health and performance, and more automated features for calibration and material changeover. In a nutshell, it’s not as big or hot as the FX20, which Markforged aims at aerospace applications, but it’s more automated and larger than the X7, plus it has a new modular architecture designed for upgradability.

Tech Specs & Price

- Technology: Fused Deposition Modeling (FDM)

- Build Volume: 375 x 300 x 300

- Heated chamber: 60ºC

- Materials: (Proprietary) Onyx (carbon-fiber filled nylon), continuous carbon fiber

- Price: $100,000

Stratasys' F3300 FDM

(Nov. 11, 2023) Stratasys says it is reclaiming its status as the cutting-edge innovator in FDM machines with the new F3300, which debuted at Formnext. The company calls it the most sophisticated FDM system they’ve ever made. No full spec sheet has been released yet, but Stratasys says the F3300 delivers twice the speed and throughput of the F900 (which isn’t going away). Print speed is up to 500 mm/s with a 270 cubic cm/hour throughput on the extruder. There are multiple extruders, an automated tool head changer, and four onboard material dryers. Stratasys just announced that Toyota has signed to purchase one. The F3300 features linear motors, more sensors, and more automation for 24/7 production.

Like the Markforged above, the Stratasys F3300 is aimed a minimizing operational labor requirements; a real pain point for companies that 3D print all day, every day. There’s a generous build volume (600 x 600 x 800 mm) and, although the chamber and extruder temperatures haven’t been released, your materials options run from ASA and carbon fiber-infused nylon to Ultem.

Tech Specs & Price

- Technology: Fused Deposition Modeling (FDM)

- Build Volume: 600 x 600 x 800 mm

- Build Resolution: 0.188 mm

- Price: not available

Raise3D's DF2 Resin

(Nov. 9, 2023) Yes, Raise3D went resin! Perhaps they thought there weren’t any ways left to optimize their popular FDM solutions, so why not take on an entirely new technology? It is a bold move to enter the crowded pro-desktop resin market but, as with everything Raise3D does, it approached resin with the end-user in mind and a focus on usability.

The company’s new DF2 Solution is just that, a “solution” for manufacturers who 3D print all day and are exhausted by the process hassles of tracking parts and loading and cleaning resin bins. Sure the DF2 DLP 3D printer has quality components and the high resolution you’d expect, but the key to this offering is the completeness of the package, which includes a washing unit, a curing unit, software, and material cartridges.

The solution boasts “traceable workflow” features, which include a “smart build plate” that integrates with both post-processing devices and has an embedded RFID tag that records the type of resin being used, in addition to washing and curing settings. This allows various operators to manage the washing and curing phases regardless of their familiarity with the products being produced.

Tech Specs & Price

- Technology: Resin DLP

- Build Volume: 200 x 112 x 300 mm

- Max Printing Speed: 25 mm/h (0.1 mm per layer)

- Min Layer Height: 50 microns

- Price: $5,000

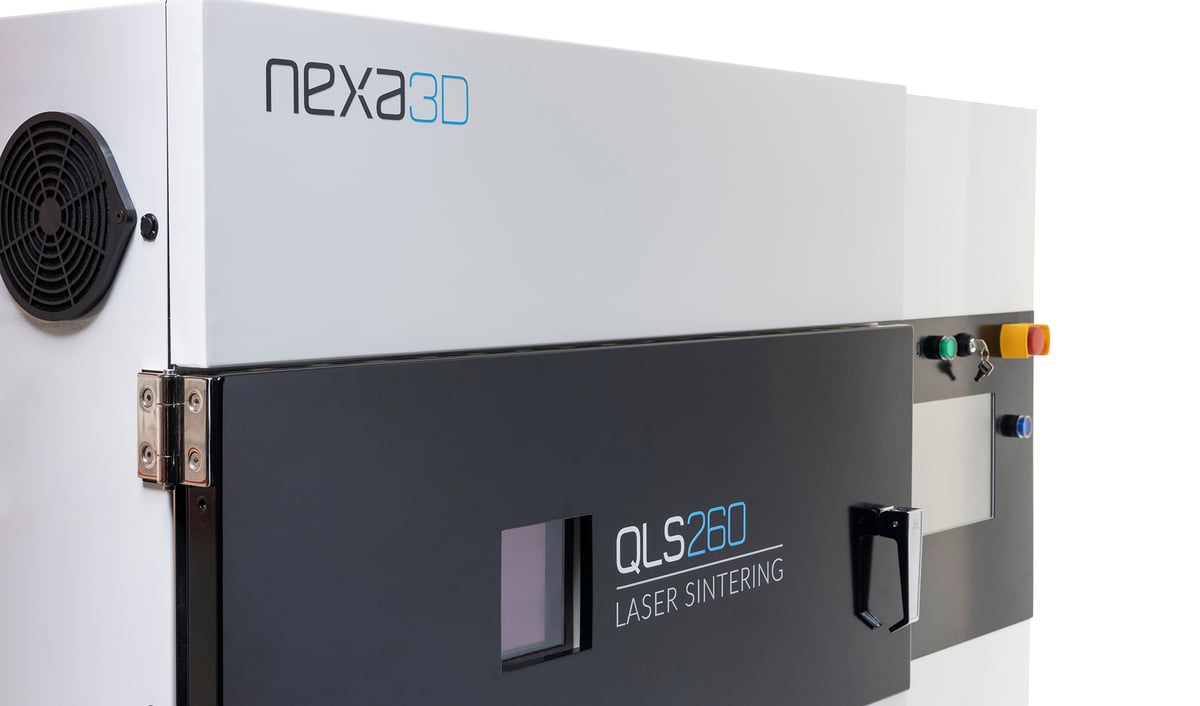

Nexa3D’s QLS 260 SLS

(Nov. 8, 2023) Nexa3D added a new SLS it its menu that’s fits in between the existing 230 and 820. The QLS 260 is an industrial laser sintering system for both powder and metal. Just a touch bigger and a touch faster than the 230, the new 260 has a 60-watt laser compared to the 230’s 30-watt and the 820’s 4 x 1,000-watt. Distinguishing it further from the rest of the QLS family is its on-board nitrogen generator.

Nexa3D also announced the availability of a new flexible TPC for SLS developed by Evonik, called Infanam TPC 8008 P. The QLS 260 is an open platform with more than 16 qualified materials including the patented metal powders from Headmade Materials.

Tech Specs & Price

- Technology: Selective Laser Sintering

- Build Volume: 230 x 230 x 250 mm

- Laser: 60W CO2

- Max. Build Speed: 22 mm / hour

- Price: $7,000

Prusa Research's Pro HT90 FDM

(Nov. 7, 2023) Prusa says it brought a new FDM to Formnext from its Prusa Pro line called the HT90. In fact, Prusa’s been working on this machine for a while ever since it acquired the machine’s developer TriLab in 2021. This delta-style, single-extruder printer is constructed to make the most of engineering-grade materials with a heated chamber to 90°C and a nozzle that reaches 500°C, which is ideal for carbon fiber-infused nylon, PEI, and even carbon-fiber PEKK.

Although the company doesn’t boast a specific max print speed, it does say the HT90 can deposit 1kg of PETG or ABS filament in just eight hours. Expect it to be commercially available sometime in late 2024.

Tech Specs & Price

- Technology: Fused Deposition Modeling (FDM)

- Build Volume: Ø300 mm x 400 mm

- Max Nozzle Temp.: 500°C

- Heated Bed: 155°C

- Heated Chamber: 90°C

- Price: >$10,000

MiniFactory's Ignite FDM

(Nov. 06, 2023) MiniFactory, the maker of the high-temperature Ultra 2 industrial FDM printer, launched its second machine called Ignite at Formnext. Also a high-temp FDM, the Ignite has almost twice the build volume of the Ultra 2 at 600 x 400 x 400 mm while offering about the same chamber temp (200°C+) and extruder temp (480°C). Materials range from ABS and ASA to Ultem and PEEK, plus, with an open material system you can choose your preferred supplier. It’s a dual extruder so you can print various support materials. Ignite also features an integrated drying solution.

Just as the Markforged and Stratasys above, the MiniFactory aims to deliver parts with less overall monitoring. It offers what it calls “real-time quality assurance technology” through its sensors that track the print as it’s made, and even offers a manufacturing document that highlights the entire printing process.

Tech Specs & Price

- Technology: Fused Deposition Modeling (FDM)

- Build Volume: 600 x 400 x 400 mm

- Max Nozzle Temp.: 480°C

- Max Chamber Temp.: 200°C+

- Price: not available

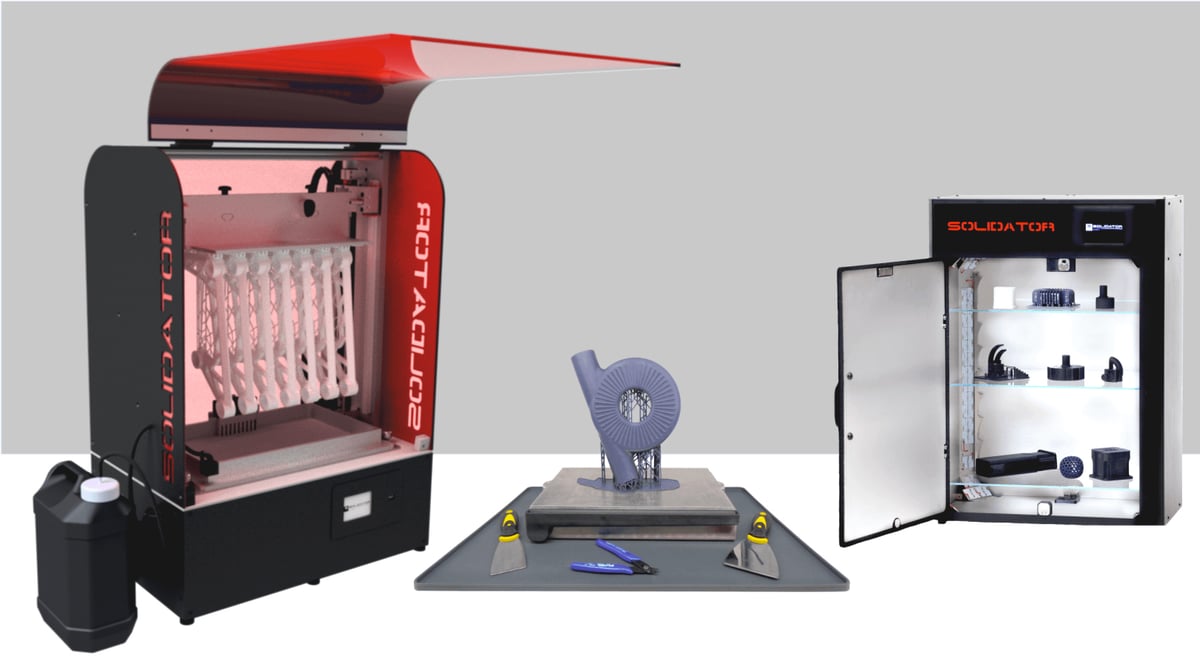

Tangible’s Solidator 8K SOL400 Resin

(Nov. 7, 2023) Tangible Engineering showed off its Solidator 8K resin 3D printer it says has a production rate of up to 9,157 cm³ per hour, which translates to a Lego brick in 5 seconds according to Tim Fischer the company’s managing director.

The Solidator is an LCD (or masked stereolithography) resin printer with a large build volume of 330 x 185 x 400 mm. The company is targeting this solution at any application that needs fast, detailed volume, such as dental models. Another advantage is that there is no need for a material reservoir the size of a building space, as is the case with SLA 3D printers. Instead, a low filling level of 800 ml is sufficient in the material tank, the resin is constantly refilled via an automatic refill system. Intro price is $18,000, but will likely increase as companies snap up this ultra-fast machine.

Tech Specs & Price

- Technology: LCD

- Build Volume: 330 x 185 x 400 mm

- Speed: 9157 cm3 per hour

- Price: ~$20,000

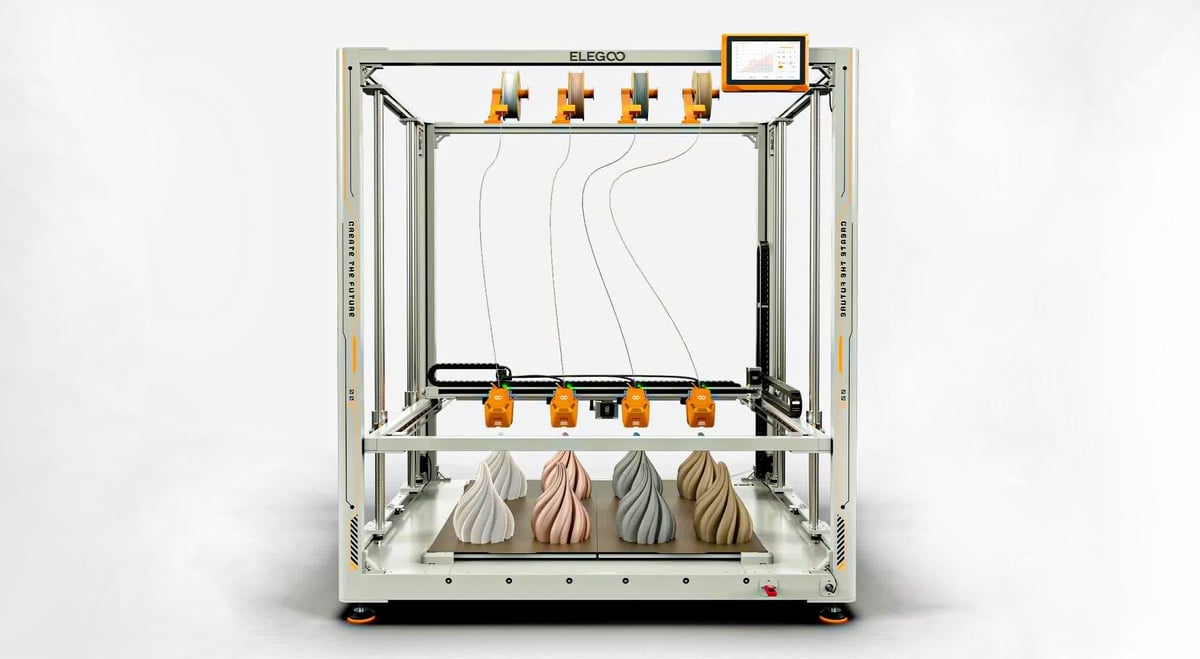

Elegoo’s OrangeStorm Giga FDM

(Nov. 1, 2023) Debuting what the company calls its first professional printer at the company’s first-ever booth at Formnext is the popular consumer brand Elegoo. The large-format OrangeStorm Giga FDM isn’t professional just because of its size; it has features. There are four 300℃ extruder nozzles that work simultaneously, so you can print four identical models or experiment with different colors and materials without worrying about nozzle drips or complications. The maximum print speed is a nice 300 mm/s.

The printer’s heated bed has four independent and individually heated PEI magnetic, high-temperature platforms, so when you’re not printing huge parts, you can focus your printer on a quarter or half of the bed. There’s also one-click automatic bed leveling, filament detection, power loss recovery, double-sided powerful cooling fans, a portable 7-inch HD screen, and caterpillar cable tracks.

Tech Specs & Price

- Technology: Fused Deposition Modeling (FDM)

- Build Volume: 800 x 800 x 1000 mm

- Max Bed Temp.: 90°C

- Max Print Speed: 300mm/s

- Price: $1,250

Orion AM’s A460 FDM

(Nov. 1, 2023) Orion AM, which specializes in high-temperature machines, launched the new Orion A460, which has the same unique tech as its AM150. The company’s thermal radiation heats the part and now the chamber during printing. This way, PEEK prints get the heat they needs to have strengths and densities surpassing injection-molding, the company says. The A460 with a build volume of 350 x 300 x 500 mm sports an integrated filament dryer and a open material system.

Tech Specs & Price

- Technology: Fused Deposition Modeling (FDM)

- Build Volume: 350 x 300 x 500 mm

- Max Nozzle Temp.: 500°C

- Max Chamber Temp.: 315°C

- Max Bed Temp.: 320°C

- Max Print Speed: 400 mm/s

- Nozzles: 0.1 mm – 0.4 mm

- Price: not available

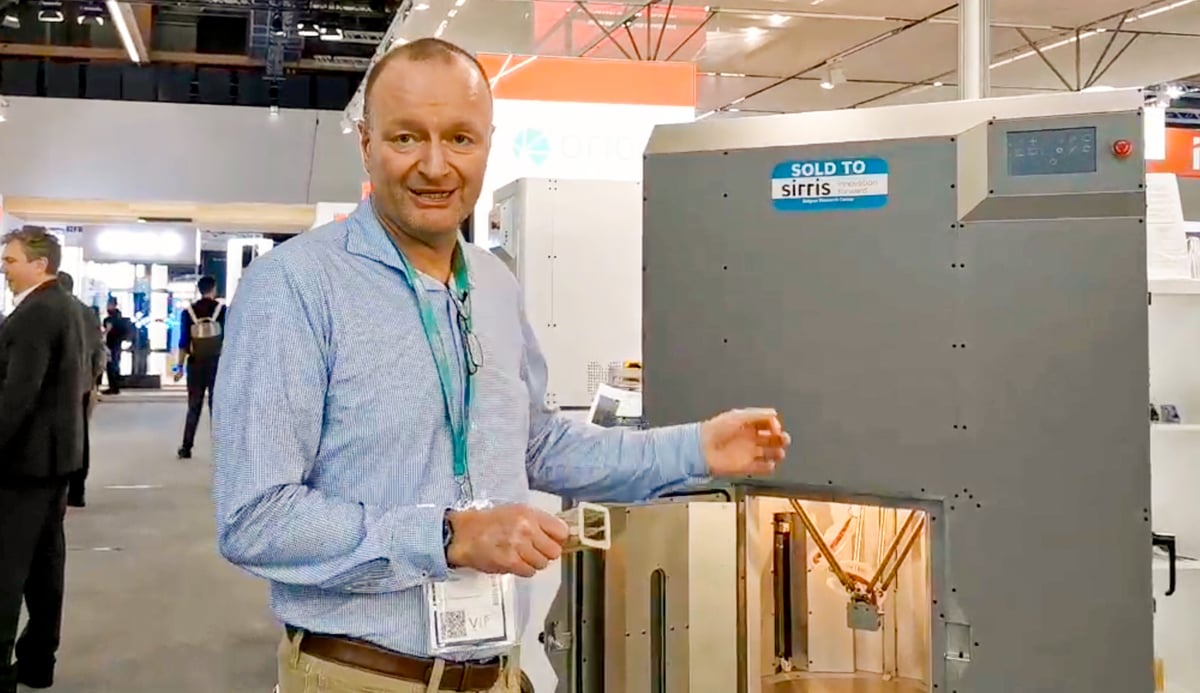

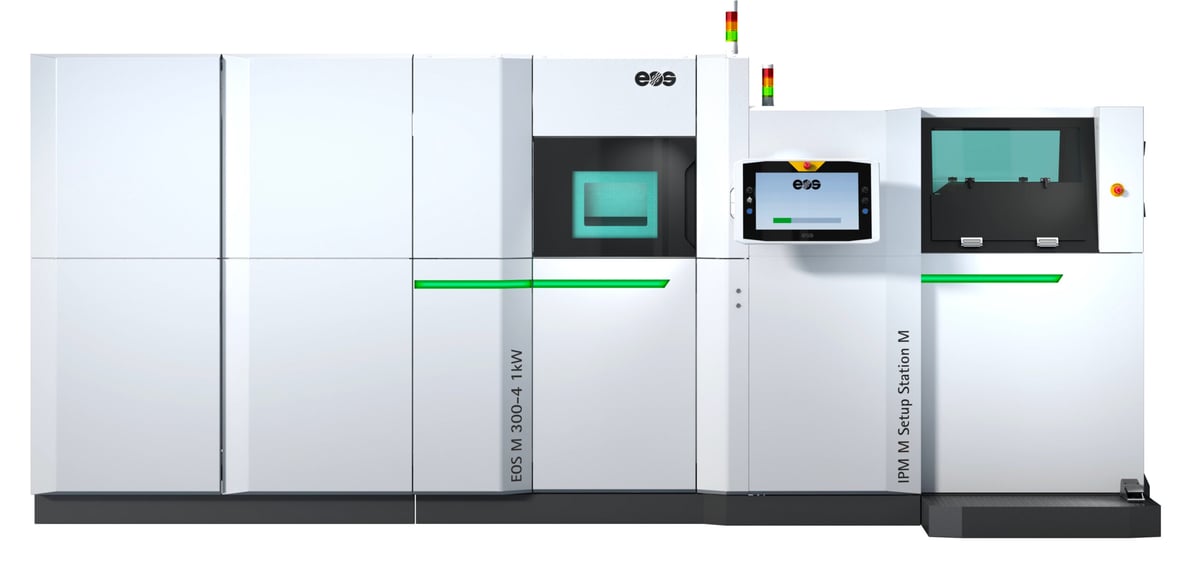

EOS' M300-4 1KW Metal LPBF

(Oct. 30, 2023) Metal laser powder bed fusion giant EOS has added a new machine to its M300-4 line, this time with up to 4 x 1,000-watt lasers.

The new M300-4 1KW system has a niche focus, EOS said at Formnext, specializing in aluminum and copper applications at the moment. What this new machine delivers is a lower cost-per-part, the company says, made possible by its already-established technology to reduce support structures and the machine’s new modular approach.

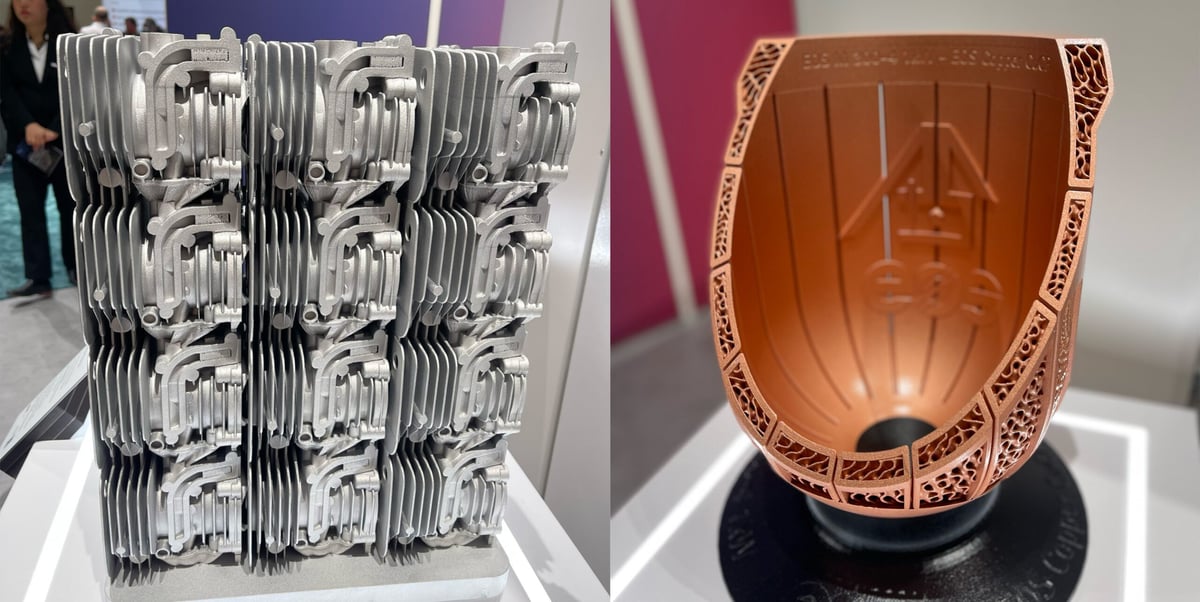

Take a look below at the prints EOS had at their Formnext booth from the new printer. Left is a build of 24 aluminum cylinder heads for a customer that makes gardening tools. The entire build took 36 hours, and for 30,000 parts, the cost was comparable to die-cast, according to EOS, but with 250kg less CO2 production. Right is a copper cold crucible used for melting metals for high-tech applications from start-up Addtoshape. The production of the crucible not only takes less energy, but it will require less energy in its use.

Tech Specs & Price

- Technology: Metal Laser Powder Bed Fusion (LPBF)

- Build Volume: 300 x 300 x 400 mm

- Min Layer thickness: 80 µm

- Build rate: 555 cm³ per hour

- Price: not available

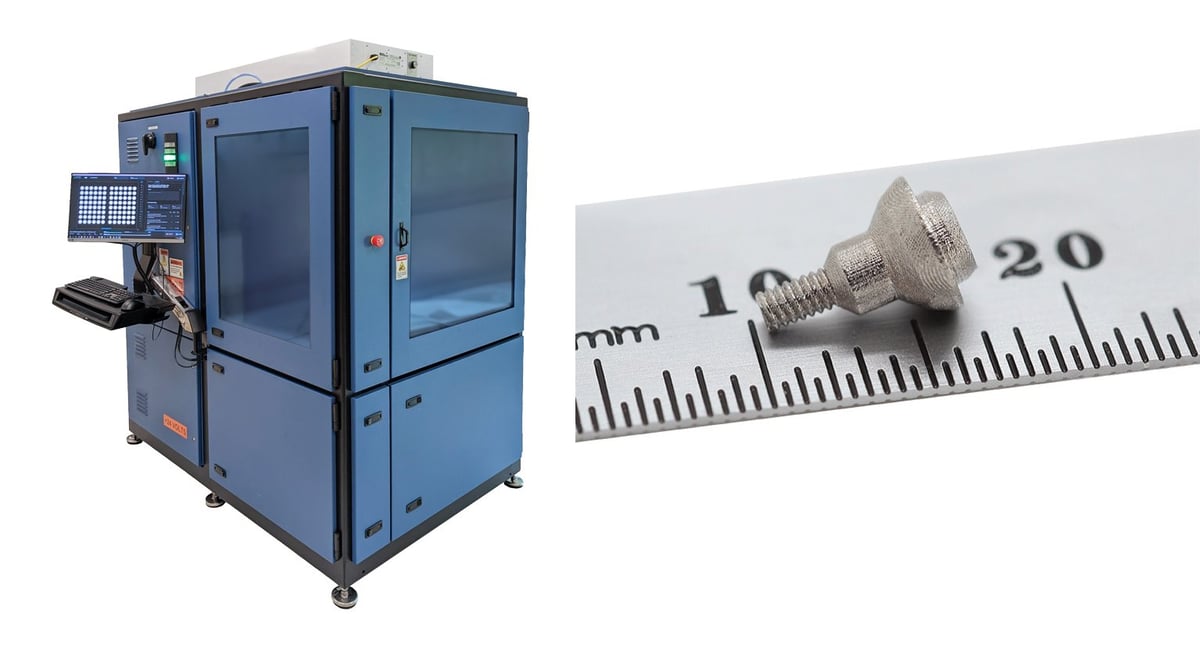

Holo's H200 Metal Lithography

(Oct. 30, 2023) The Holo H200 isn’t exactly new, but metal lithography 3D prints from this machine were only avaialble as a service from Holo. Now, the company is offering its Holo H200 for commercial sale.

The H200 produces parts with 50-micron details and within 25-micron tolerances. Final parts match the surface smoothness of commercial metal injection mold parts, the company says. Speed is another hallmark of the system; the dental abutment pictured above was printed in just eight seconds.

Holo’s “PureForm” technology commercial material offering currently includes stainless steel grades 17-4PH and 316L, along with pure copper. The portfolio is extending to include Inconel and Ti-64 on a pre-commercial basis. All commercial materials from Holo meet the MPIF-35 specifications.

Tech Specs & Price

- Technology: Metal Lithography

- Build Volume: 244 x 195 x 200 mm

- Min. Resolution: 50 microns

- Price: not available

Aon3D’s Hylo FDM

(Oct. 29, 2023) Aon3D has come out with a new printer called Hylo that replaces its previous one, called M2+, which we had on several of our top-picks lists. The Hylo is a high-temp FDM, like the three above, that focuses on a range of applications including tooling, jigs and fixtures, end-use parts, and industrial rapid prototyping.

Unlike the offerings from Stratasys and Markforged, the Hylo like the MiniFactory is an open material platform so you can pick any material brand for carbon fiber composites and high performance polymers, including PEEK.

With an expansive 650 x 500 x 500 mm build volume, the Hylo boasts print speeds of up to 500 mm/s and IDEX-enabled duplication and support modes. Beyond its tech specs, Aon3D is calling it a “smart” 3D printer because it features 25 integrated sensors for process controls and monitoring. Along with the machine, Aon3D introduced a forthcoming software solution called Basis “intelligent-slicing and in-process monitoring” that it says will turn process variability into part confidence.

Tech Specs & Price

- Technology: Fused Deposition Modeling (FDM)

- Build Volume: 650 x 450 x 450 mm

- Max Chamber Temp.: 250ºC

- Max Bed Temp.: 250ºC

- Max Nozzle Temp.: 500ºC

- Price: not available

Modix's Core-Meter FDM

(Oct. 18, 2023) Modix, the maker of large-scale 3D printers, has a new focus: affordable large-scale 3D printers. As consumers and small businesses become more attracted to large-format 3D printing there’s a growing market for FDMs that can manage a meter square print volume, but won’t break the bank. This is just what Modix is offering with its new Modix Core-Meter (1 x 1 x 1 meter build volume).

Modix says the Core-Meter is the second in its new line of large 3D printers designed to provide cost-effective solutions. The first in the series was the Core-60, launched in June.

With an attractive starting price of only $7,000, the Core-Meter is a stripped-down version of the company’s existing Modix Big-Meter, priced at $13,500. Modix hasn’t released all of the specifications yet, but did say the Core-Meter has a single print head, while the Big-Meter has an IDEX dual print head. The Core doesn’t have an enclosure, an air filtration system, or a filament dryer like the Big-Meter, but these are all available as add-ons.

The Core-Meter is scheduled for release in the first quarter of 2024 and as soon as Modix releases more specs, you can find them here.

Tech Specs & Price

- Technology: Fused Deposition Modeling (FDM)

- Build Volume: 1,000 x 1,000 x 1,000 mm

- Max Nozzle Temp.: 290°C

- Nozzles: 0.4mm

- Price: $7,000

Incus' Hammer Pro40 Metal Lithography

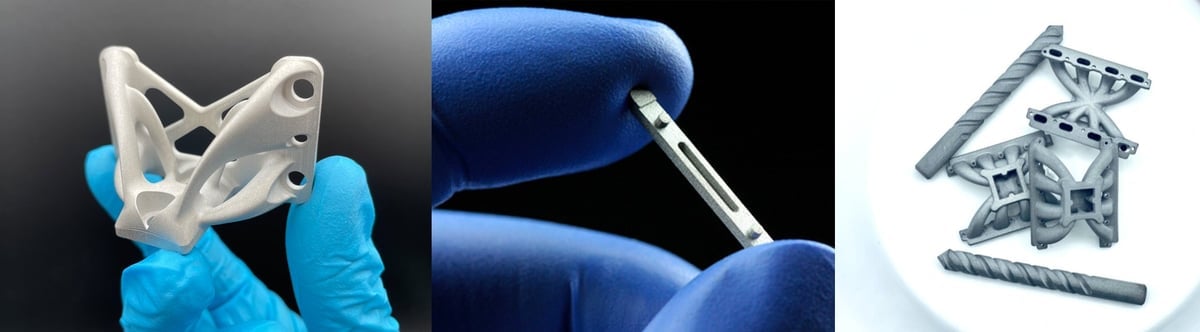

(Oct. 18, 2023) If you’re in the market for a 3D printer to produce small and intricate metal parts, you’ll want to check out the new Hammer Pro40 from Incus.

The company says its new metal lithography (metal particles suspended in a photopolymer base then sintered) machine is designed for the large-scale production of complex geometries, such as those required in micro-robotics, dentistry, medicine, automotive, and jewelry.

With a potential throughput of 700 cm³ per hour and a resolution of 40 microns, the Hammer Pro40 represents a sevenfold increase in printing speed compared to the Hammer Lab35, the company says, and a fourfold lower cost per cm³. Plus, the Pro40 can produce much larger parts than the Lab35.

The Hammer Pro40 produces parts in stainless steels, titanium, and custom materials.

Tech Specs & Price

- Technology: Metal Lithography

- Build Volume: 200 x 153.6 x 150 mm

- Air Purification: Activated Carbon Filter, HEPA Filter

- Materials: Stainless steels, titanium, custom

- Max Print Speed: up to 700 cm³/h

- Feedstock: Proprietary metal infused resin

Mosaic Manufacturing's Array FDM Farm

(Oct. 16, 2023) The new Array ($80,000 – $95,000) from Mosaic is a four-printer cabinet with robotic part removal and 32-material availability for 24/7 production 3D printing.

It houses four Mosaic Element or high-temperature Element HT FDM 3D printers, a robotic gantry system, and a cart to store the completed prints and empty print beds.

Each Element 3D printer inside Array can have eight materials bays each, automatically switching between them to enable a single part with up to eight materials. The material changer is called Palette X. It automatically feeds a new material to the single extruder “avoiding complex multi-nozzle calibration and messy nozzle dripping,” the company says.

In fact, this patented material changer is what Mosaic has had on the market for years. The Mosaic Palette entered the scene back in 2014 and made a splash with a successfully funded Kickstarter campaign. The Palette’s goal was to bring multi-color 3D printing to any machine and the original device did that in an innovative way. The new X version can now exchange more materials than be before.

With eight materials per printer, you could pack your Array with 32 different materials, ranging from PLA to PEEK.

Tech Specs & Price

- 4x Element or Element HT 3D printers

- Automated robot that picks up finish prints and prepares the printer for the next print.

- Automated bed changing

- 32 automated material pods

- Fume extraction hookup

- Mobile storage cart for finish builds

- Auto remote monitoring systems

- Palette X material changer

- Price: $80,000 with 4 Element 3D printers, $95,000 with 4 Element HT3D printers

Pollen AM o2 Gen FDM

(Oct. 12, 2023) French 3D printer maker Pollen AM opted to launch its new printer at the 3D PRINT in Paris in October but you can check it out at their booth at Formnext. The new generation of its extrusion-based 3D printer is called PAM (Pellet Additive Manufacturing) o2 and it’s twice as fast as the previous version, although Pollen hasn’t released an actual speed.

It’s hard to believe Pollen AM is already a 10-year-old company. As a pioneer in 3D printing using pellet-based material instead of filament, the company has been ahead of its time, but competition is getting stronger, thus the upgrade.

The new PAM o2 replaces the company’s previous three options with three new ones. There’s a printer tailored specifically for thermoplastics pellets (PAM o2), one for high-temperature thermoplastics pellets (PAM o2 HT), and one for metal and ceramic pellets (PAM o2 MC).

What’s different with the o2 generation is an “increase of productivity”, the company says, thanks to electronics that perform better in high-temperature conditions. There are also new benefits from open programming and enhanced mechanical architecture, with the ability to automate user-defined tasks, a lighter structure and redesigned motion transmission. So pretty much an overhaul.

Most important is performance. As we mentioned, the o2 generation has print speeds twice as fast as the previous generation and machine set-up times 7-times faster, the company says.

The machines are also quieter, use 10% less electricity, and have easier maintenance and simplified system diagnostics.

Tech Specs & Price

- Technology: FDM

- Print volume: 300 x 300 x 300 mm

- Min Layer Height: 40 microns

- Nozzle sizes: 0.25 mm, 0.30 mm, 0.40 mm, 0.60 mm, 0.80 mm, 1 mm, 1.5 mm, 2 mm

- Max. extruder temp.: 350°C, 450°C (HT, MC),

- Chamber temp.: 90℃ (HT, MC)

- Max. bed temp.: 150°C, 300°C (HT) optional disk, 200°C (MC)

- Materials: most all injection molding grade polymers and metals

- Material format: Pellets

- Price: TBD

Desktop Metal's ETEC Pro XL Resin

(Oct. 10, 2023) It’s hard to tell Desktop Metal’s new printers from its new marketing spin. The “new” ETEC Pro XL is has the same technical specifications as Desktop Metal’s Einstein Pro XL launched in 2022, but dressed in gray and aimed at a new group of users.

In 2021, Desktop Metal bought a 3D printer maker called EnvisionTec which had a top performing resin DLP printer it launched in 2017 called the Perfactory 4 LED XXL. Desktop Metal took EnvisionTec’s tech, made it better and faster (HyperPrint technology), and relaunched the printer in 2022 as the Einstein Pro XL from Desktop Metal’s heathcare division called Desktop Health.

Of course, there’s no reason to limit this DLP tech to just dental labs, thus the ETEC Pro XL. Priced the same as the Einstein Pro XL, the ETEC Pro XL can process a wide range of industrial, jewelry casting, and health photopolymers — including specified resins from third-party providers, such as Henkel Loctite, Evonik, and BASF.

Bambu Lab's X1E FDM

(Oct. 10, 2023) Bambu Lab’s newest FDM 3D printer brings more heat and office-friendly features for 3D printing pros. To appeal to what Bambu Lab says is the “evolving needs” of its customers, the latest addition to the flagship X1 series is specifically crafted to meet professional engineering requirements. The X1E is the X1 Carbon but with more for engineers, which may be what the E means.

What do engineers need, you may ask? According to Bambu Lab, what appeals to professionals is safety in their office, thus the heavy-duty air filtration system; a higher level of network security, thus the new WPA2-enterprise Wi-Fi authentication and an ethernet port connection; and the ability to print with engineering-grade materials, such as carbon fiber nylon, thus the new hotter 320ºC nozzle temp and active chamber heating.

The X1E offers the option to connect devices through its newly added ethernet port, ensuring network communication in crowded wireless signal environments. The X1E’s WPA2-Enterprise Wi-Fi authentication and individual physical kill switches for both Wi-Fi and ethernet meet the stringent network security requirements of companies looking to rapidly and secretly prototype their next new product.

The X1E can operate independently without a connection to Bambu Cloud Service, so its fully functional within a local network. Customers can remotely control the X1E through LAN communication without requiring an Internet connection.

Tech Specs & Price

- Technology: Fused Deposition Modeling (FDM)

- Build Volume: 256 x 256 x 256 mm

- Max Nozzle Temp.: 320ºC

- Max Chamber Temp.: 60ºC actively heated

- Max Build Plate Temp.: 120ºC

- Air Purification: Activated Carbon Filter, HEPA Filter

- Price with AMS Combo: $2,500

- Max Print Speed: 500 mm/s

- Connectivity Multi-frequency: Wi-Fi, Ethernet

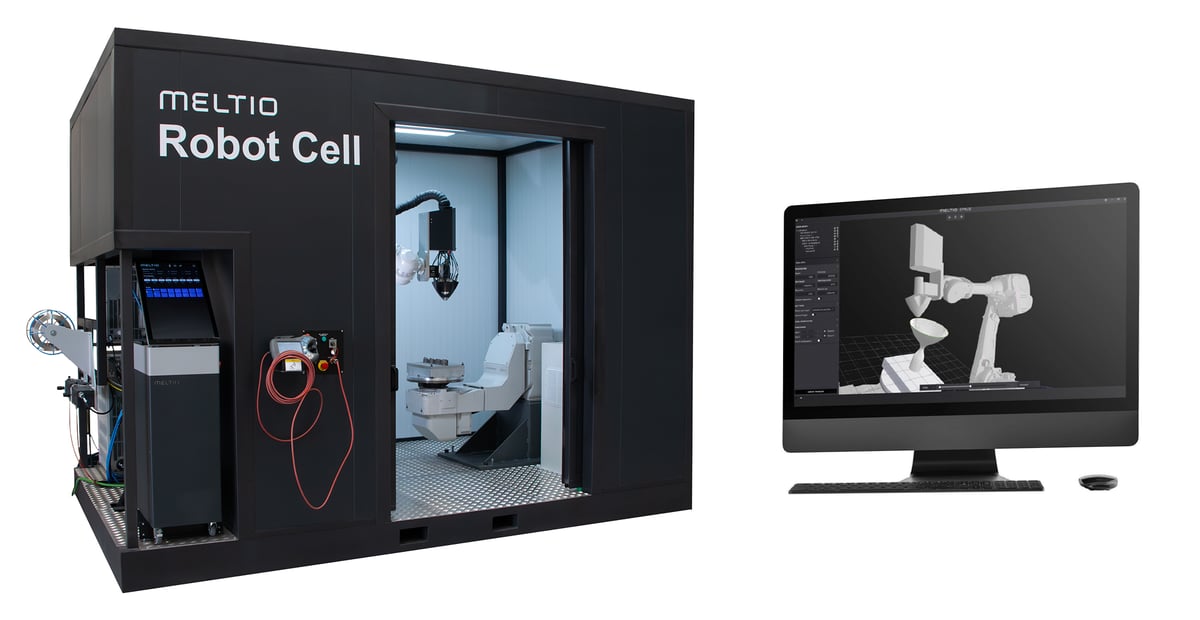

Meltio's Robot Cell DED

(Sept. 18, 2023) Meltio has come out with a new turnkey robotic arm metal 3D printing cell it says gives industrial manufacturers a safer and more reliable environment in which to fabricate metal parts.

Meltio specializes in wire-fed direct energy deposition (DED) technology — in other words, using a laser to melt metal wire as it’s deposited. The company’s technology has long integrated with a range of robotic arms to enable metal 3D printing, but now, this new hardware system is a ready-to-use cell for robotic metal 3D printing that removes the integration process and long assembly lead times.

Meltio takes its existing laser DED technology and its recently launched slicing software, Meltio Space, and contains it into a single cell to standardize the process with monitoring and safety features.

The Meltio Robot Cell workspace includes a robot and positioner installed on a self-supporting platform, a laser-safe enclosure, the Meltio Engine, Meltio Space, and accessories.

Meltio Robot Cell is designed as a plug-and-play system with a single electrical power supply and a single inert gas supply. The cell is certified and tested to operate with an ABB robotic arm as standard configuration, but other brand arms are possible.

For industry sectors, such as aeronautics and space, that have certifications or low oxidation requirements during manufacturing with high oxidizing materials like Titanium and related alloys, Meltio is working on a inert bubble for the system.

Tech Specs & Price

- Technology: Metal Direct Energy Deposition

- Print volume: 2,000 x 1,000 x 1,000 mm

- Gas supply: Ar

- Materials: Stainless steel 316L, 308L, mild steel ER70S, titanium 64, nickel 718, +

- Material format: Metal wire

- Price: $250,000 – $300,000

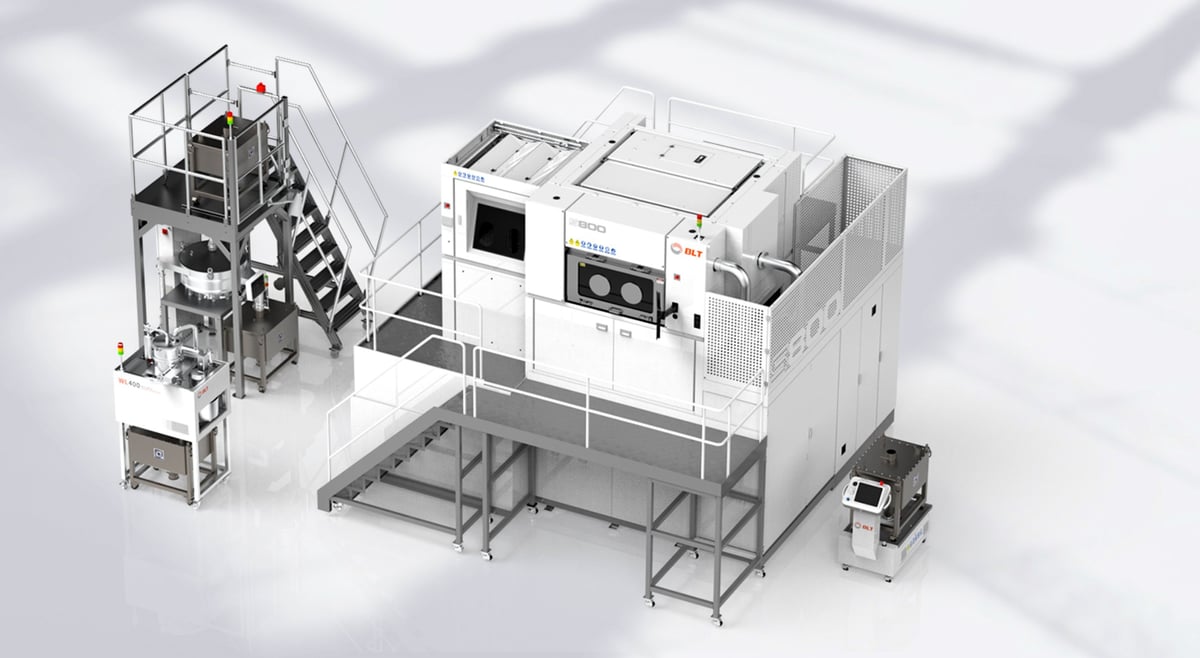

BLT's BLT-S800 Metal LPBF

(Sept. 14, 2023) BLT (Bright Laser Technologies), the metal 3D printer giant from China offering more than a dozen metal laser powder bed fusion 3D printers, keeps pushing boundaries. The company’s latest machine, the BLT-S800, is about the size of a two-car garage and aimed at aviation, automative, and heavy industry.

Coming in second place as far as the number of lasers among this month’s new metal laser powder bed fusion machines, the S800 “only” has 20. Actually, its laser configuration is customizable ranging from six 500W, eight 500W, or ten 500W lasers and an option to double the 10-laser set up. (Next month, BLT is said to be launching the BLT-S1500 with 26 lasers!)

With 10 lasers, the print speed is a zippy 250 cm³/h and the build volume for the S800 is a roomy 800 x 800 x 600 mm. It can be equipped with a single or bi-directional recoater.

Tech Specs & Price

- Technology: Metal Laser Powder Bed Fusion

- Print volume: 800 x 800 x 600 mm

- Print Speed: Up to 250 cm³/h

- Laser: up to 20 x 500W

- Laser scan speed: 7 m/s

- Gas supply: Ar

- Materials: Titanium alloy, aluminum alloy, superalloy, stainless steel, high-strength steel, tool steel

- Material format: Metal powder

- Price: >$500,000

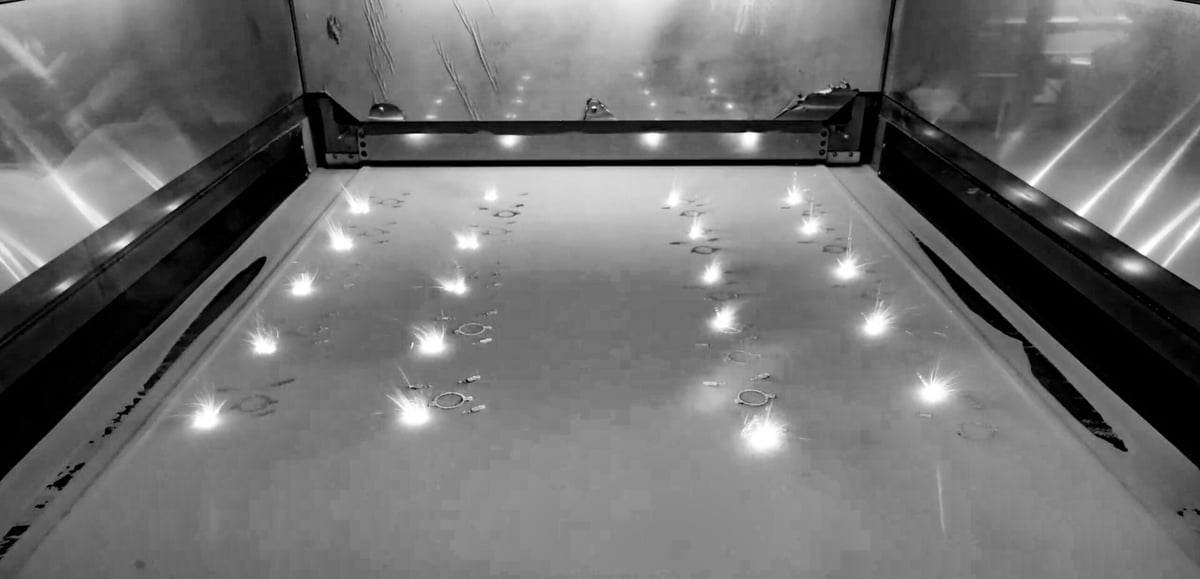

Eplus3D's EP-M1550 Metal LPBF

(Sept. 15, 2023) Eplus3D launches a 95-laser powder bed fusion machine the size of a four-car garage!

Okay, we’re kidding about that one, but with the launch of the new 25-laser Eplus3D EP-M1550, it begs the question: Is there a limit to lasers?

The standard configuration of the EP-M1550 is just 16 lasers with an option to expand to 25. The company says it “pushes the boundaries of what’s possible in metal powder bed fusion,” and it would seem they’re right.

This newest member of their large-platform printing family (they offer 12 printers total) is the largest system on the market when you count laser capability and build platform (1,558 x 1,558 x 1,200 mm).

With 16 synchronized lasers, the build rate is an impressive 650 cm³/h.

There’s also an option to extend the height up to 2,000 mm, providing a functional printing volume of 2,670 liters. With the options of either 500W or 700W lasers, the machine print a wide range of materials, including titanium alloys, aluminum alloys, stainless steels, and mold steels. Layer thicknesses range from 20 – 120 microns.

Tech Specs & Price

- Technology: Metal Laser Powder Bed Fusion

- Print volume: 1,558 x 1,558 x 1,200 mm

- Min Layer Height: 20 microns

- Print Speed: 650 cm³/h

- Lasers: 16 or 25, 500 or 700 watt

- Spot size: 70 – 120 micron

- Laser scan speed: 8 m/s

- Gas supply: Ar / N2

- Weight: 70,000 kg

- Materials: titanium alloys, aluminum alloys, stainless steels, mold steels+

- Material format: Metal powder

- Price: Well, if you have to ask …

HBD's E1000 Metal LPBF

(Sept. 11, 2023) HBD, the large Chinese laser powder bed fusion 3D printer maker, launched its very large E1000 machine this month. There’s no trove of machine details available and it is unclear if the machine is even available outside of China. Yet we are keeping tabs on this company in the run-up to the Formnext expo in Frankfurt, Germany, in November, where HBD will showcase their much smaller machines.

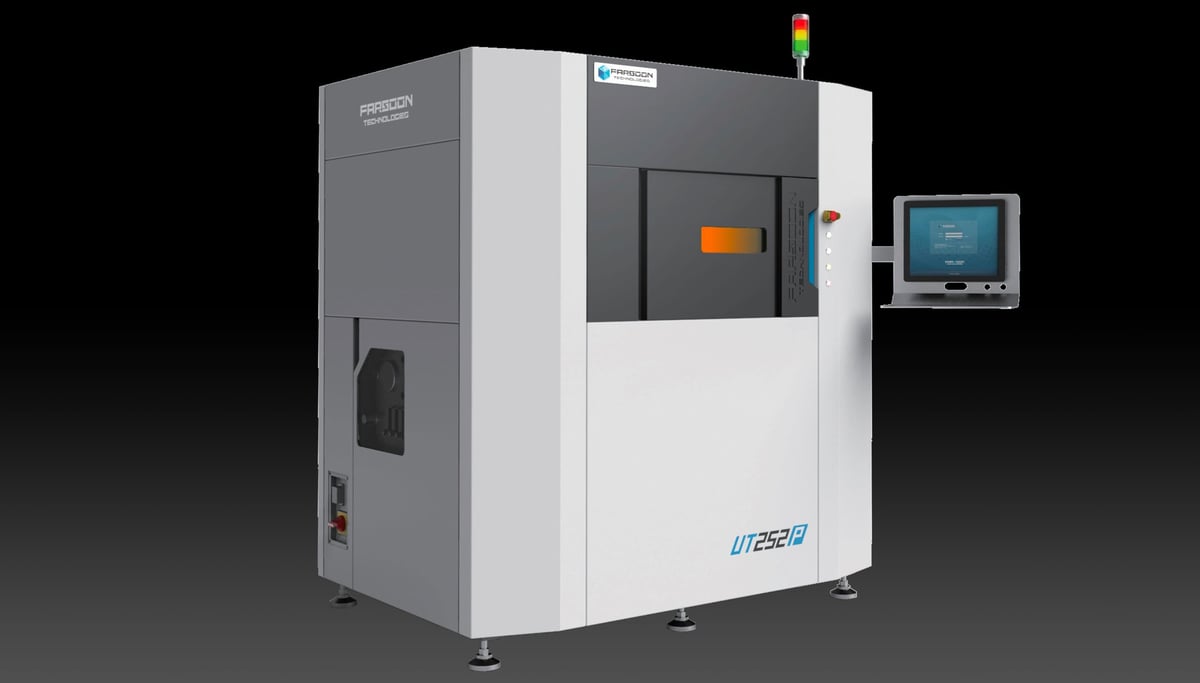

Farsoon’s HT-252P SLS

(Sept. 14, 2023) Less of a new printer and more of a tweak to an existing printer, Farsoon Technology’s “ultra temperature” configuration of its 252P selective laser sintering (SLS) machine features a higher chamber temperature.

First, there was the “high temperature” HT-252P with a max chamber temp of 230°C, then came the “super temperature” ST-52P (280°C), and now the “ultra temperature” HT-252P, which can process materials with a high melting point of over 340°C, such as PI (polyamide) and PTFE (polytetrafluoroethylene). If the 252Ps get any hotter, we’re afraid Farsoon has run out of adjectives.

Spec-wise, the ultra has the same build chamber (250 x 250 x 320 mm) and laser power (100W CO2) as the Super. Farsoon says the 252P series is “a popular choice” for “technical research institutes, leading chemical manufacturers, and small-scale production service providers.”

“With our philosophy of developing truly open platform systems, Farsoon’s polymer application team has been collaborating with material suppliers on optimization of high-temperature powder material for the polymer LPBF process, with recent success sintering one PAEK family material with a high melting point over 340°C,” says Farsoon.

Ultra-high-temperature materials are expensive. The company says its powder optimization process can achieve a low refresh rate with a high potential for reduced material cost.

If you want one, you’ll have to wait, unless you’re in China. The UT-252P is now open to beta testers in China only.

Tech Specs & Price

- Technology: Selective Laser Sintering

- Print volume: 250 x 250 x 320 mm

- Min Layer Height: 20 microns

- Print Speed: Up to 2.5 l/h

- Laser: CO2 laser, 1 x 100W

- Laser scan speed: 10 m/s

- Gas supply: N2

- Materials: PI (polyamide), PTFE (polytetrafluoroethylene)+

- Material format: Polymer powder

- Price: not yet released

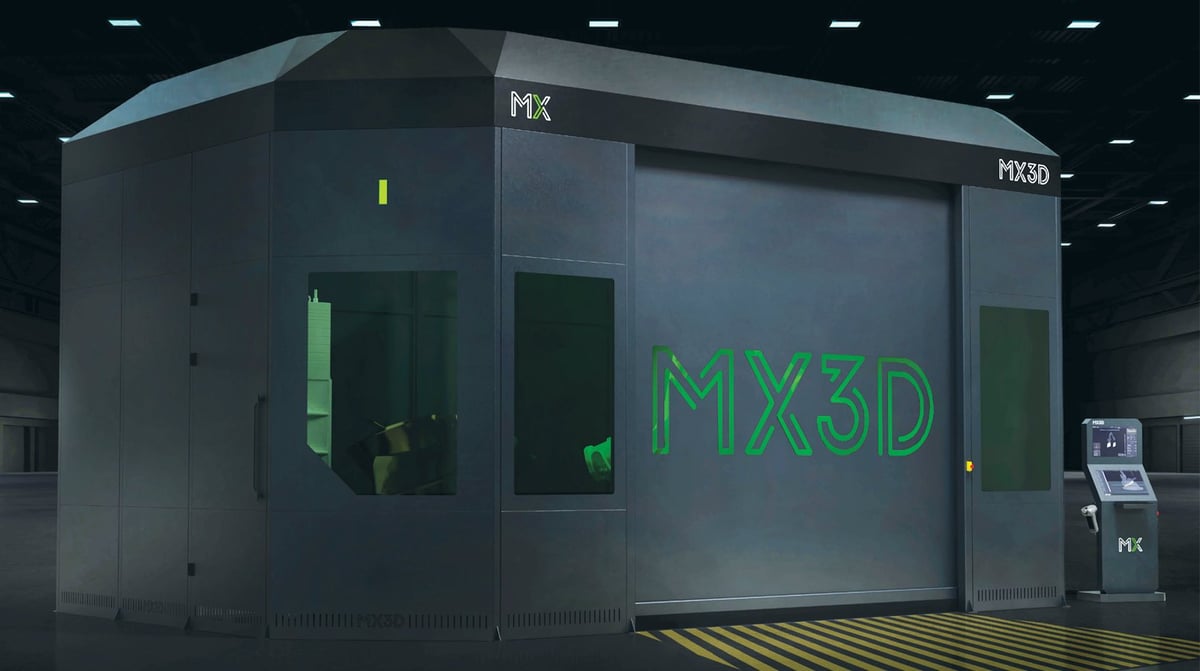

MX3D's MX Metal AM System WAAM

If your shipyard needs a five-ton propeller in a hurry, Dutch metal 3D printer maker MX3D has a solution. Its new MX Metal AM System, which can make metal parts as large as 6 x 1.5 x 3.6 meters out of any weldable metal, targets manufacturers in marine, energy, oil & gas, construction, and heavy industry.

In fact, anywhere large cast or forged metal parts are too expensive and slow to produce with traditional methods, MX3D offers an alternative that’s not only faster and cheaper, but about the size of a shipping container and installable practically anywhere.

The MX Metal AM System is a wire arc additive manufacturing (WAAM) setup incorporating MX3D’s existing technology with new software and accessories that enable customers to supersize their metal WAAM 3D printing.

For everyone who admires MX3D’s stainless steel 3D printed bridge in Amsterdam, you can now have that technology.

Just like MX3D’s smaller system, the M1, the MX is highly customizable. Customers have a choice of power source and 8-axis heavy-duty industrial robotic arm brand (ABB, Kuka). The robotic arms are offered in your choice of reach, payload, force, and accuracy.

“Several of our customers see opportunities for applying WAAM on much bigger parts … to accelerate the lead time, bring down cost, and reshore production of critical parts,” says Gijs van der Velden, MX3D’s CEO.

More features shared with the M1, the MX is an enveloped system that has interchangeable tool attachments to transform into a hybrid additive and subtractive system.

Tech Specs & Price

- Technology: Wire arc additive manufacturing (WAAM)

- Print volume: 6 x 1.5 x 3.6 m

- Machine footprint: 9.3 x 5.3 x 4.9 m

- Accuracy: 0.05 mm

- Speed: 10 kg/h

- Materials: Any weldable metal

- Price: >$500,000

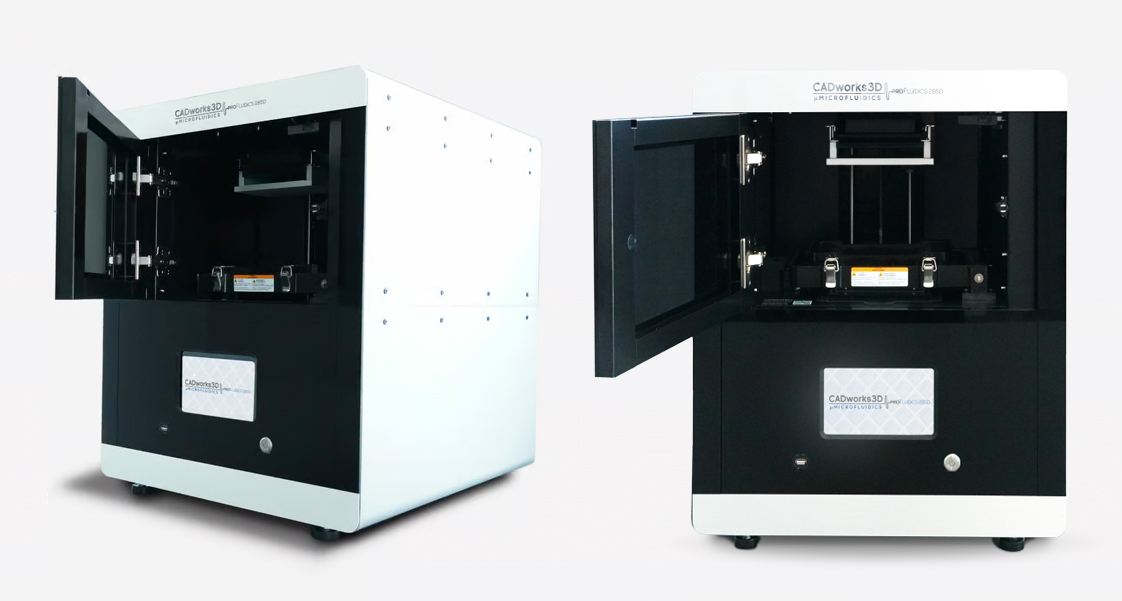

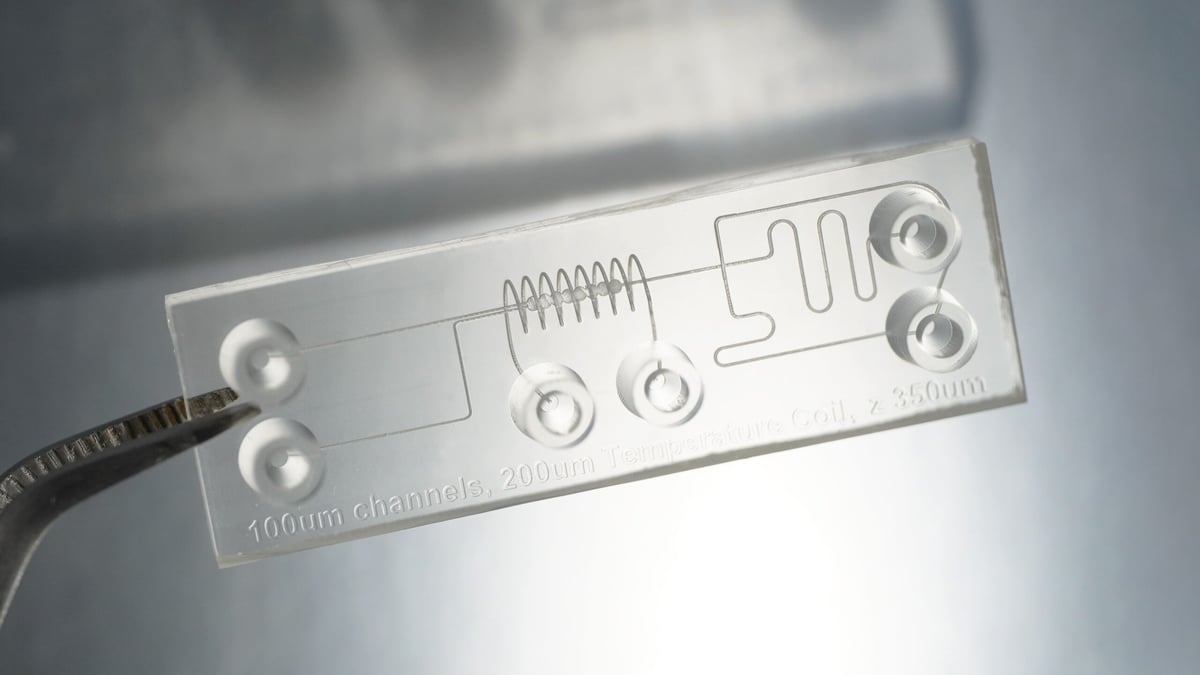

CADworks3D's ProFluidics 285D Resin

(Aug. 17, 2023) Canadian specialty 3D printer maker and 3D material developer CADworks3D launched its newest ProFluidics 285D 3D printer. It used DLP technology specifically to fabricate microfluidic devices.

For the past 8 years, CADworks3D’s primary focus has been on accelerating microfluidic research. With the ability to print 100µm channels reliably, the company says, the ProFluidics 285D meets the growing demand for smaller print features. Fabricated devices exhibit improved performance, geometric accuracy, optical transparency and better laminar flow analysis. “Using our material, the price of a single 5g device costs approximately $2.05 – $2.55.”

ProFluidics 285D 3D printer supports a variety of techniques such as direct printing or PDMS replica molding.

With its 28.5µm resolution, the ProFluidics 285D can successfully print features with 180-degree turns, complex serpentine channels and other intricate geometries.

Tech Specs & Price

- Technology: Micro Digital Light Processing

- Print volume: 110 x 62 x 120 mm

- Min Layer Height: 5 microns

- Material: CADworks3D Resin

- Price: not yet released

Airwolf 3D's Evo 2X FDM

(Aug. 2, 2023) Airwolf 3D, the Las Vegas-based 3D printer manufacturer, aims to fill a need in the market for a larger format filament-based machine with its new Evo 2X. It is one of the largest heated 3D printers — capable of handling carbon fiber-filled nylon — that will still fit on a workbench and is priced under $20K.

“Ever since we established our business in 2012, customers have consistently requested larger printers,” says Erick Wolf, founder of Airwolf 3D.

However, it has taken until now for the company to overcome the challenges that accompany developing larger heated enclosed printers. “The power requirements alone for producing printers capable of creating full-size parts in ABS thermoplastic can be daunting,” says Wolf, noting that the Evo 2X can be plugged into a standard 110-volt wall outlet.

Tech Specs & Price

- Technology: FDM

- Print volume: 609.6 x 304.8 x 558.8 mm

- Min Layer Height: 40 microns

- Speed: 80 mm/s

- Nozzle sizes: 0.35 mm, 0.50 mm, 0.80 mm, 1.0 mm, 1.2 mm

- Max. extruder temp.: 315℃

- Chamber temp.: 70℃

- Max. bed temp.: 160℃

- Materials: ABS, carbon fiber nylon (PA), PET, PLA, ASA, PETG, +

- Material format: Filament

- Price: $17,000

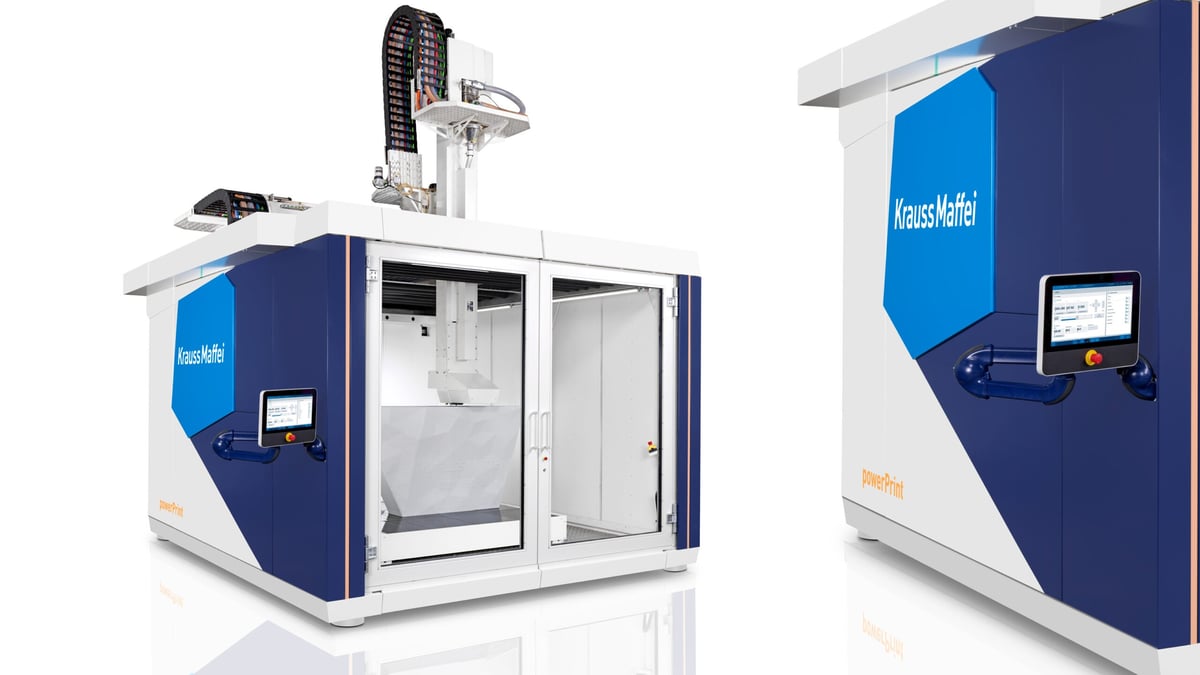

KraussMaffei's PowerPrint FDM

(July 26, 2023) At nearly twice the size of almost all other fully enclosed heated FDM 3D printers on the market, the new PowerPrint from KraussMaffei is designed for applications from mold making and facade panels to pipes, fittings, and prototype construction parts.

The massive 2 x 2.5 x 2-meter build volume fits the PowerPrint in between large-format FDMs and robotic arm 3D printers. (For reference, you could fit about 60 UltiMaker Method Xs inside the PowerPrint’s chamber.)

Couple the size with a high-temperature (400ºC) extruder, heated bed (140°C), and a heated (60ºC) vacuum chamber, and this new 3D printer can deliver parts in a wide range of thermoplastics, including ABS, carbon fiber reinforced nylon, ASA, TPU, PP, and recycled options.

Tech Specs

- Technology: FDM

- Print volume: 2 x 2.5 x 2 m

- Speed: 30kg/h

- Nozzle sizes: 2-20 mm

- Max. extruder temp.: 400℃

- Chamber temp.: 60℃

- Max. bed temp.: 140℃

- Materials: ABS, carbon fiber nylon (PA), PET, PLA, ASA, TPU, PP, +

- Material format: Pellets

BCN3D's Omega I60 FDM

(June 23, 2023) The folks at the Nissan production plant in Spain might be the inspiration behind the new Omega I60 from BCN3D. Nissan adopted BCN3D’s other 3D printers, the Epsilon series, some years ago to produce jigs, fixtures, and all types of shop-floor tools. By all accounts, the partnership was – and is – mutually beneficial, but if you look closely at the new Omega, you can almost see an Epsilon W50 in shop overalls.

The Omega I60 is bigger, sturdier, and has a heated chamber and bed to make quick work (300 mm/s) of dimensionally accurate tooling in heavy-duty materials, such as carbon fiber nylon. It has an integrated filament dryer for when you forget to put your materials away and an easy-swap nozzle change feature.

BCN3D took what users loved about the Epsilon — like the independent dual extruders (IDEX), XYZ autocalibration, and, let’s not forget, the affordable price tag — and fortified it into a shop-floor workhorse.

The I60, which is an open-material platform (no fees), will sell for just over $20K, making it one of the most affordable, higher-temp FDMs on the market. We take a closer look in the article linked below:

Tech Specs & Price

- Technology: FDM

- Mechanics: Independent dual extruders (IDEX)

- Print volume: 450 x 300 x 450 mm

- Max extruder temp: 350ºC

- Heated chamber: to 70ºC

- Heated bed: to 120ºC

- Min layer height: 0.05 mm

- Max print speed: 300 mm/s

- Price: $22,000

Solidscape's Muse Wax Material Jetting

(June 6, 2023) As 3D printers become a standard tool in dentists’ labs, architects’ offices, and jewelers’ studios, efficiency and ease of use are top attributes. These professionals are less interested in adjusting printer settings and more focused on receiving the part they expect consistently.

A compact, one-click operation wax model 3D printer designed specifically for jewelers is just what Solidscape says its customers want, so it developed its smallest and most affordable wax 3D printer yet, the Muse. Solidscape, a company by Prodways, the large French industrial 3D printer maker, already offers a line of precision wax printers aimed at commercial jewelers looking for large throughputs, starting above $20,000

Priced under $15,000, Muse is designed to bring wax model 3D printing to any size custom jewelry studio, according to Solidscape. It features material jetting technology similar to the larger Solidscape machines.

Tech Specs & Price

- Technology: Material Jetting

- Build area: 76.2 x 76.2 x 47.7 mm

- Layer height: 25.4 microns

- Accuracy: +/- 25.4 microns – 127 microns

- Materials: proprietary wax, soluble support

- Price: ~$15,000

UltiMaker's Method XL FDM

(May 23, 2023) The Method series of fused deposition modeling (FDM) 3D printers from Makerbot (now called UltiMaker after its 2022 merger) has been the go-to desktop machine for anyone needing reliable prints in engineering-grade materials at an affordable price (sub $10k).

But now, the new Method XL, which offers five times the print volume of the previous versions while maintaining the printing precision, can address a new customer, UltiMaker’s VP of Product Johan-Till Broer tells All3DP.

“The Method XL is more in the space where industrial printers play today, appealing to a more mature user,” says Broer.

UltiMaker is aiming the XL at companies that want to adopt 3D printing but may not yet have an established business case, or the full buy-in yet from their organization to invest in a six-figure industrial solution. The XL provides the reliability, materials, and ease of use to help companies uncover cost savings and integrate 3D printing into their workflows and processes, according to UltiMaker.

“Our mission is to drive the adoption of professional 3D printing,” says Broer. “And one way to do that is by developing very application-specific solutions. So you will see more of that kind of thinking and those kinds of products coming out of UltiMaker.”

Tech Specs & Price

- Technology: Fused Deposition Modeling (FDM)

- Architecture: Dual Extruder

- Print Volume: 305 x 305 x 320 mm

- Extruders: 2, with swappable print cores

- Nozzle diameters: 0.4 mm

- Nozzle temperature: 300 °C

- Heated build plate: 105 °C

- Min. layer resolution: 100 mm

- Touch Screen: 5-inch full-color touchscreen

- Supported files: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG

- Price: $13,000

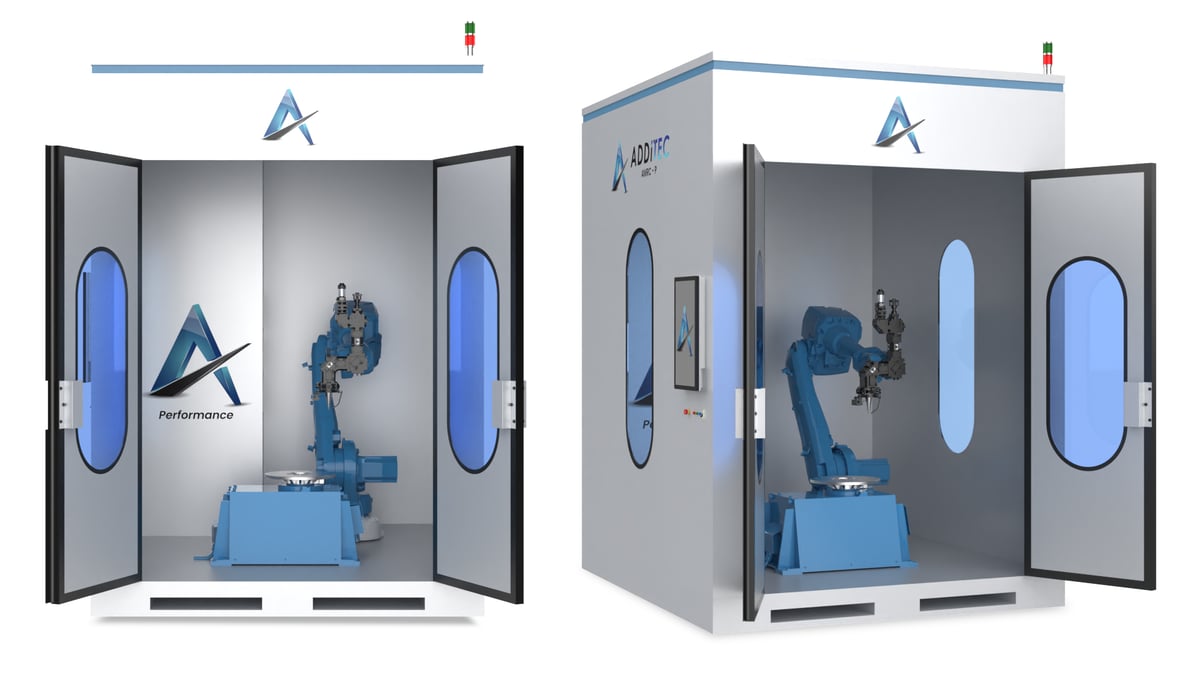

Additec's Performance AMRC-P Metal DED

(May 20, 2023) The ability to produce solid metal replacement parts at or close to the point of need is the promise of several additive manufacturing technologies gaining ground in the oil & gas industry and among militaries, where operational shutdowns are extremely costly and the lead times for traditional forged replacement parts are long.

Although there are several methods of producing large metal industrial parts quickly, few are as small or as fast as the new portable additive manufacturing robot cell from Florida-based Additec.

The Performance AMRC-P (additive manufacturing robot cell portable) is designed to be deployable at sites where industrial metal replacement parts are critical, such as oil fields, nuclear plants, mines, and remote factories. The cell footprint is a mere 2.29 x 2.74 x 3.23 meters (7.5′ x 9′ x 10.6′).

Tech Specs & Price

- Technology: Laser wire DED

- Laser: 1 x 6 kW fiber laser

- Layer height: 0.8 – 1.2 mm

- Speed: deposition rate 4 kg/hr

- Build volume: 2.29 x 2.74 x 3.23 meters (7.5′ x 9′ x 10.6′)

- Wire feedstock: 0.8 – 1.2 mm iron, nickel, titanium, copper, aluminum alloys

- Shielding: localized (argon or nitrogen)

- Inert chamber: vacuum and argon

- Robotic arm partners: ABB, Fanuc, Kawasaki, Yaskawa

- Price: $499,000

Valcun's Minerva Molten Aluminum Extrusion Printer

(May 15, 2023) Flemish startup Valcun is launching an aluminum extrusion metal 3D metal printer called Minerva, presumably after the goddess of handicrafts and the arts. The company is now taking pre-orders, but an official commercial availability has not yet been announced.

Nevertheless, it is an interesting development, and possibly a printer that can jump into the spot left open by Xerox’s exit from the aluminum molten extrusion market. The Minerva isn’t anywhere near the size of the Xerox ElmX, but that may actually pay off. A smaller, deployable, compact, metal extrusion solution could be the key to this technology’s adoption.

The printer enables 3D printing with economical wire feedstock and enables overhangs of up to 70 degrees without the need for a support structure. Valcun says the Minerva comes with an open parameter set, open materials, open data acquisition, and open nozzle architecture. Although only aluminum 4008, 4043, 6061, and 6082 have been officially qualified on the machine, the open settings make it attractive for anyone who wants to experiment with metal extrusion.

In fact, Valcun says their “Molten Metal Deposition” technology is material-independent, and new materials like magnesium, copper, silver, gold, and steel, could be added to the portfolio.

Print Specs

- Technology: molten metal deposition

- Build volume: 125 x 125 x 200mm

- Gas shielding: Argon

- Nozzle temp: 700°C – 900°C

- Bed temp: 400°C – 600°C

- Layer height: .5 mm

- Feedstock: Wire

- Price: not released

Nexa3D’s XiP Pro Resin

(May 2, 2023) Industrial 3D printer maker Nexa3D today launched a Pro version of the desktop resin machine it launched in early 2022. The XiP Pro is even zippier than the original XiP, the company says. It’s also bigger and almost 10 times the price. But there are a lot of pro features in this new version aimed at enabling businesses to print more and print faster without sacrificing any fine details.

Boosting print speed from 18 verticle cm per hour to 24 vertical cm per hour, the ZiP Pro can produce its entire build volume (292 x 163 x 410 mm) in under two hours. This measure is the foundation of the company’s claims of dramatically improved throughput.

But more than speed, this new Pro version offers several other feature upgrades. For example, the resolution is even greater because the XiP Pro has a 7K resolution LCD screen compared to 4K on the standard XiP.

The 7K screen has a 46-micron pixel size that, with anti-aliasing technology, can achieve a surface quality that appears even finer.

Tech Specs & Price

- Technology: Resin, LCD

- Build Volume: 292 x 163 x 410 mm or 19.5L

- LCD Resolution: 7K (6480 x 3600)

- Pixel Size: 46 microns

- Min. Print Resolution: 25 microns

- Min. Layer Height: 50 microns

- Product Dimensions: 622 x 447 x 895 mm

- Software: NexaX Pro or NexaX Basic

- Materials: open, 19+ validated

- Price: $60,000

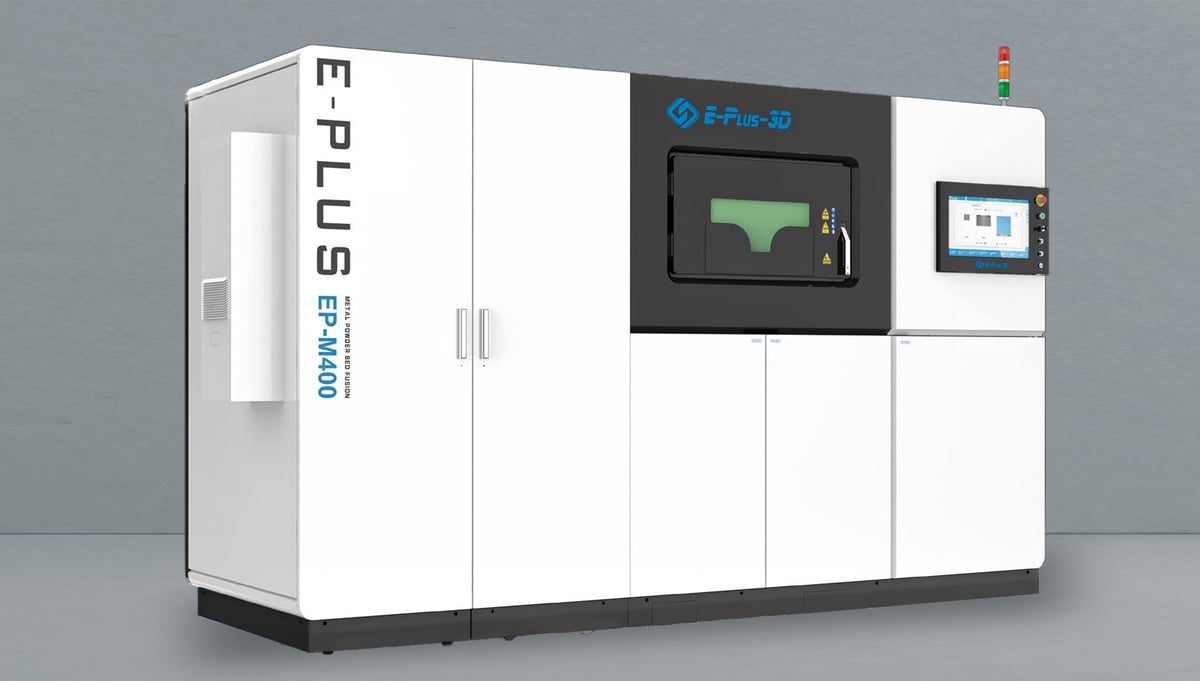

Eplus3D's EP-M400 Metal LPBF

(April 28, 2023) Eplus3D, a top manufacturer of metal, polymer, and sand 3D printers, has added a new metal 3D printer to its menu of 11 laser powder bed fusion machines.

The new EP-M400, which features variable single, dual, or quad-laser configuration and a 405 x 405 x 450 mm build volume, is a size smaller than the company’s M450, which only has a dual laser. The company’s other quad-laser is the much larger M650.

Eplus3D’s Deputy General Manager, Enis Jost says that Eplus is aiming for the sweet spot in both size and power. The M400 is twice as fast as the M450 (120 cm3 per hour vs. 55 cm3 per hour) but offers the size and front-loading structure customers prefer. If you’re comparing quad-laser machine speed, the M400 is as fast as the SLM Solutions SLM 500.

Eplus3D hopes the M400 will expand the application of multi-laser metal 3D printing in multiple industries. Although the company calls the M400 an entry into metal 3D printing, the newest machine is tailored to customers who are expecting to expand their business through large metal printing with quad-laser power at a lower cost than machines with similar technology (without sharing the printer’s price tag).

Tech Specs

- Technology: Laser Powder Bed Fusion (LPBF)

- Build Volume: 405 x 405 x 450 mm

- Laser: 1, 2, or 4, 500 -W Fiber lasers

- Laser Spot Size: 80 – 120 µm

- Max Scan Speed: 8 m/s

- Layer Thickness: 20 – 120 μm

- Materials: Open. Titanium Alloy, Aluminium Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, and more.

- Gas Supply: Ar/N₂

- Software: Eplus3D EPHatch

- Price: not yet available

Impossible Objects' CBAM 25 Carbon Fiber Sheet Lamination

(Apr. 24, 2023) Impossible Objects is launching a new composite carbon fiber 3D printer called CBAM 25 machine, which it says enables extremely fast volume manufacturing.

CBAM stands for composite-based additive manufacturing, which is a type of sheet lamination technology that uses long-fiber carbon or fiberglass sheets. On each sheet, a slice of the part is printed with thermal fluid, then coated with a polymer powder, such as PEEK or nylon 12. Layers are stacked, then heated to the melting points and compressed. Through a mechanical or chemical process, the unbonded portions of the sheet are removed, revealing the final part.

Along with parts and tools for a wide variety of industries, the CBAM technology is used to create parts for electronics manufacturing and soldering process.

“With high-performance, composite materials, such as carbon fiber PEEK, the CBAM 25 produces parts with better strength-to-weight ratios compared to aluminum and better temperature performance than conventional materials,” according to Impossible Objects.

The CBAM 25 is nearly 7 times faster than the company CBAM 2 3D printer with a larger build volume.

Tech Specs

- Technology: Sheet Lamination

- Printing Volume: 457 x 449 x 101 mm

- Printing Speed: 11,000 cm3 / hour

- Minimum Wall Thickness: 2 mm

- Layer Thickness: 50-60 microns

- Price: TBD

3D Systems' NextDent LCD1 Resin

(Mar. 13, 2023) 3D Systems, one of the world’s largest 3D printing companies with a vast portfolio of machines and materials, just launched its smallest 3D printer, the NextDent LCD1, to co-inside with the International Dental Show, in Cologne, Germany. Measuring about the size of a drip coffee maker, this resin 3D printer can sit comfortably on any dental office countertop.

The compact footprint, combined with basic touchscreen operation, makes this an attractive printer for small operations looking to enter dental 3D printing to produce low volumes of parts, such as molds, trays, guides, full and partial dentures, splints, and long-term temporaries. The NextDent LCD1 aims to “accelerate the adoption of additive manufacturing as part of every dentist’s workflow and provide opportunities to improve the patient experience,” the company says.

Tech Specs

- Technology: LCD

- Printing Volume: 128 x 80 x 140 mm

- Machine Size: 271 (W) x 292 (L) x 416 (H) mm

- Pixel Size: 49 μm

- Printer Wavelength: 405 nm

- Printing Speed: 4.5 cm/hr.

- Material System: NextDent resins / open platform

- XY Resolution: 49 μm

- Slice Thickness: 30 – 150 μm

- Resin Wavelength: 385 ~ 405 mm

- Price: $6,000 – $8,000 (All3DP estimate)

Structo's ST-01 Resin

(Feb. 23, 2023) Singapore-based Structo, a maker of dental 3D printers, unveiled the new ST-01 and ST-32 at the LMT Lab Day dental lab conference in Chicago.

The masked stereolithography (MSLA) machine is designed for high throughput digital production in medium to large dental and orthodontic laboratories, the company says. Particularly interesting are the machines’ speed and semi-automated design for lights-out manufacturing of clear aligner models.

ST-01 has a large build volume and a throughput of nine clear aligner models every 15 minutes. Paired with Structo’s solventless

post-processing workflow, you can have parts ready for thermoforming in 30 minutes, the company says.

ST-32 allows for the continuous printing of clear aligner models with minimal labor by eliminating several manual steps. Essentially it’s the ST-o1 with a gantry and part storage system that automates the changeover process in between print jobs with an EZrelease magnetic sheet. Once a print job is completed, the gantry system removes the sheet with the freshly-printed parts and stores them in a magazine within the cell. It will then insert a new EZrelease sheet to start a new print job.

This automation allows dental laboratories to run after-hours print jobs, returning the next day to a magazine of printed models ready for the next phase in their appliance-making process. At peak capacity, ST-32 will be able to print up to 24 EZrelease sheets in eight hours without needing any technician intervention.

Both units are expected to become available in 2023.

Tech Specs

- Technology: LCD, also called masked stereolithography (MSLA)

- Print volume: 221 x 129 x 200 mm

- Print Speed:

- Resolution: 4920 x 2880 (5K)

- Min layer height: 50 microns

- Price: TBD

Stratasys' J3 DentaJet Material Jetting

(Feb. 15, 2023) Stratasys, a giant in polymer 3D printing, introduced the J3 DentaJet 3D printer. This entry-level, multi-material printer enables dental labs to produce highly accurate mixed applications in a single tray simultaneously. The J3 is a smaller version of the company’s popular J5 DentaJet, but doesn’t have quite all the features of the J5. For example, it prints in three materials plus support materials compared to the J5’s five materials but has the same build volume.

The J3 DentaJet 3D printer features biocompatible resins (clear, rigid, and flexible). It can create mixed parts for crown and bridge models, implantology (model, surgical guides, and gingiva masks), and orthodontic models, all in the same print job. Its sizable circular build tray and high-speed mode can help labs to scale and boost output. PolyJet, Stratasys’ proprietary jetting technology, cures the printed parts during the print process, minimizing post-processing.

Without specifying a print speed, Stratasys says the J3 can print up to 37 aligner arches in 3 hours and 13 minutes. The J3 DentaJet is operated and managed through GrabCAD Print, Stratasys’ software for streamlining print preparation workflow. The new printer is expected to ship in March.

Tech Specs

- Technology: material jetting

- Print volume: 140 x 200 x 190 mm

- Min layer height: 18 microns

- Materials: color resin, biocompatible resin, support material

- Price: ~$50,000

3D Systems' ProJet MJP 2500W Plus Material Jetting

(Feb. 14, 2023) 3D printer maker giant 3D Systems just launched a new, high-resolution 3D printer specifically for high-capacity wax 3D printed jewelry patterns.

The ProJet MJP 2500W Plus is touted as bringing new speed and precision to lost wax casting, delivering 100% wax casting patterns in hours. The smooth pure wax casting patterns require less finishing, the company says, which also reduces precious metal waste.

The ProJet MJP 2500W Plus 3D printer includes a new feature the company is calling “ZHD print”, presumably for Z-axis High Definition, which delivers better vertical resolution without an increase in wax material consumption.

When used as part of 3D Systems’ comprehensive MultiJet Printing solution for jewelry casting comprising the ProJet MJP 2500W Plus, VisiJet wax materials, and 3D Sprint software, customers are able to quickly and consistently generate micro-detail, precision, 100% wax sacrificial casting patterns for high capacity jewelry production.

The ProJet MJP 2500W Plus is available now.

Tech Specs

- Technology: resin-based material jetting called MultiJet Printing (MJP)

- Build volume: 294 x 211 x 144 mm

- Print Speed: 69 cm3/hr

- Resolution: 8 µm (Z)

- Min layer height: 8 µm

- Materials: 100% wax

- Price: $70,000 – $85,000 (All3DP estimate)

B9Creations' Elite Micro Resin

(Feb. 7, 2023) B9Creations is a resin 3D printer maker specializing in high-resolution applications for various industries, including jewelry, medical, and prototyping. The new Elite Micro represents the company’s first foray into micro 3D printing, which they aim to make accessible since this is by far one of the lower-priced machines that can achieve a 10-micron layer height and 20-micro resolution.

The Elite Micro’s DLP technology offers a native pixel size of 20 microns with microscale features, such as wall thicknesses down to 30 microns and holes down to 100 microns, to deliver micro parts at production quality, the company says.

Resins include clear, engineering & design resins, but the printer can also use third-party materials or have B9Creations develop a custom resin for you.

The B9 Elite Micro prints with a range of resins, including HD Slate high-detail, HD Clear resin, and Robust – ABS/PC engineering-grade resin. Slate is formulated for highly detailed, microscale components, and with no z-bleed, parts have crisp detail, the company says. Parts with the Clear resin can be made fully transparent with polishing or coating. The Elite Micro is also open to third-party materials, or customers can also work with B9Creations to develop a custom resin.

The B9 Elite Micro is the first platform in the company’s Elite Series.

The machine comes with two resin vats, a 1-kg bottle of resin, a finishing kit, and remote factory startup assistance.

Tech Specs

- Technology: Resin digital light processing (DLP)

- Print volume: 38.4 x 21.6 x 127 mm

- Print Speed: 1 – 7 mm/hr

- Resolution: <20 µm

- Min layer height: 10 µm

- Materials: B9 Material Suite (HD Slate, HD Clear, ABS/PC) and open to 3rd-party materials

- Wavelength: 385 nm

- Price: $30,000

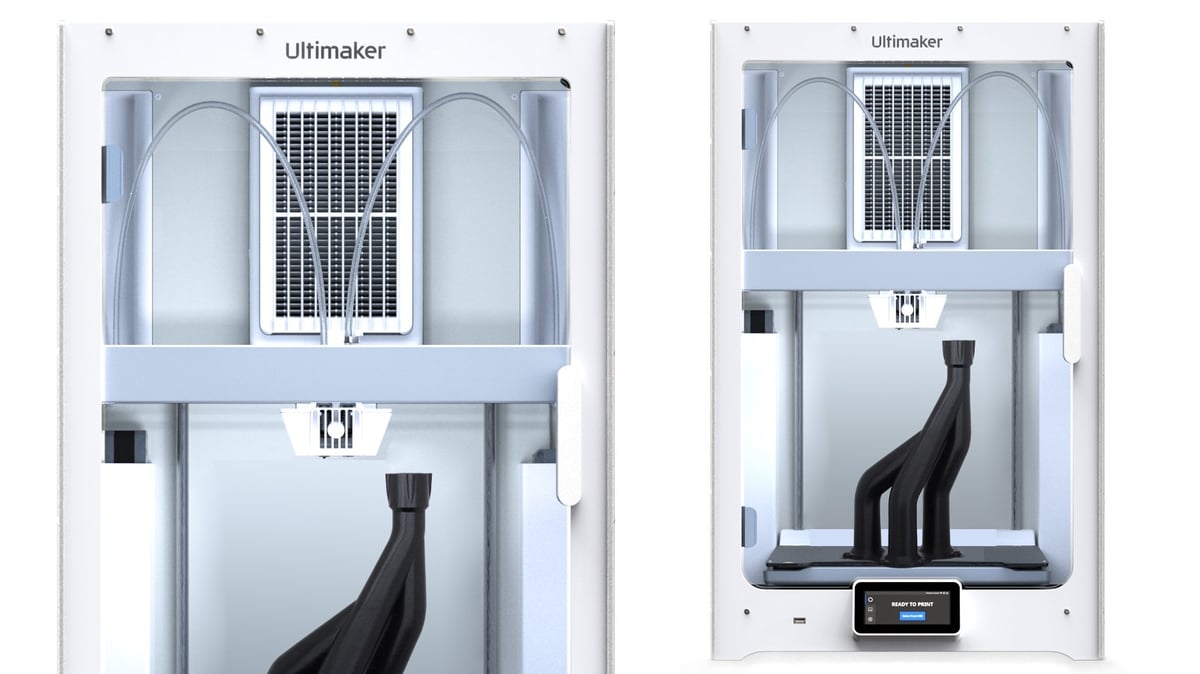

UltiMaker S7 Pro FDM

(Jan. 24, 2023) Although UltiMaker had been making constant updates to its flagship professional FDM, the S5, ever since it launched in 2016, it was about time to a new version. Granted, the new S7 is 90% the S5, but the improvements really will make a difference in reliability, consistency, and accuracy.

The S7 is not a replacement for the S5 but includes enhancements the company says target its professional “power users.”

We go into all the new technical details in our exclusive chat with UltiMaker CTO Miguel Calvo in the article linked below, but in brief, the S7 has better temperature control, updated bed leveling, and a built-in fan and filter.

Tech Specs

- Technology: Fused Deposition Modeling (FDM)

- Build volume: 330 x 240 x 300 mm

- Print Speed: 69 cm3/hr

- Nozzle temperature: 180-280 °C

- Heated build plate: 20-140 °C

- Min. layer resolution: 20 microns with a 0.25 mm nozzle

- Screen: 4.7-inch full-color touchscreen

- Supported files: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG

- Operating Sound: < 50 dB

- Price: $8,000 – $9,000

License: The text of "All the New Professional 3D Printers Launched in 2023" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.