Advances in 3D printing technology over the past 20 years have changed the way many industries operate and the architectural sector is no exception. 3D printing has found a home at many stages in the property development lifecycle, and one can easily argue that architecture firms benefit the most from the advantages 3D printing brings in terms of speed, detail, cost, and efficiency. Traditional model-making service providers are also rapidly embracing the technology that helps them produce more precise models, faster and cheaper.

My company, UK-based Hobs 3D, has been 3D printing architecture models for years now, and I’d like to share some of our expertise to get you started.

Here, we’ll cover the steps you need to know about printers, software, and methods to start making your own architecture models, including:

- Using computer-aided design software to craft your 3D model

- Prepping your model for 3D printing

- Feeding your model into your printer’s slicer software

- Printing your model

- Refining your model by assembling its parts, sanding surfaces, painting, etc.

We’ll also walk you through what to expect when working with a third party 3D printer to have your models custom made.

How Architects Benefit From 3D Printing

But first, let’s take a step back and look at why you might want to print an architectural model.

Architects play a pivotal role in the development of any new property. They have a level of involvement in building projects from conception to construction that is second only to property owners. As such, there are plenty of ways 3D printing can impact the success of a venture.

Design Development

As any designer will tell you, creation is an iterative process. New buildings and specific design features are imagined, drawn (physically or digitally), and improved over and over again.

3D printing allows the architect to build a physical representation of a design quickly and relatively inexpensively, thereby improving the final concept in a time- and cost-efficient manner.

Bid Winning

An architecture firm may find itself in a competition to promote their concept over a competitor. For particularly important projects, drawings and on-screen visualizations might not be enough to highlight the supremacy of your design. A 3D printed representation is often used to help a concept stand out from the crowd and ultimately win the contract.

Client Presentation

Final approval of a building design is another important stage where 3D printing can play an important role. Clients typically feel more comfortable making a judgement on a physical representation of a building or development than on a digital representation.

Public Consultation

It is common for a project to require some level of approval from a local council or planning authority, and these entities will typically require some level of consultation with the local public to discus the architect’s plans. A 3D model can put a design into context and help people outside of the industry understand what a development will mean for their community.

Sales & Marketing

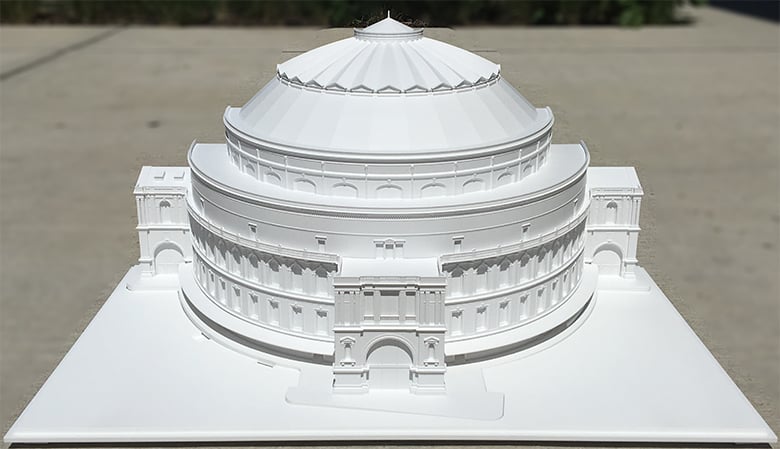

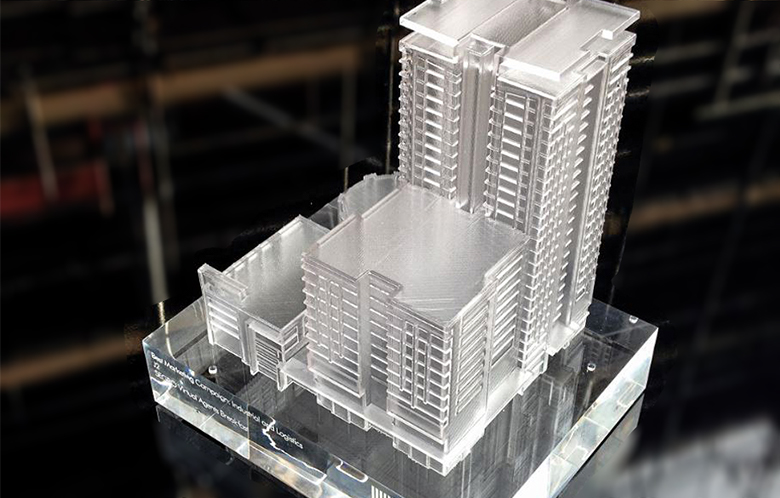

Once the build nears completion, property developers often build highly detailed scale models of their developments based on the architectural designs that assist in the selling of residential and commercial units. 3D printing is combined with traditional modeling techniques to create large scale representations that are works of art in their own right.

Types of 3D Printing Suitable for Architecture

You’ve decided that you want to 3D print your architectural models. Your next question will be, what printer do I need?

Picking a printer depends on your budget, your familiarity with the machines, and a host of other factors that are unique to your business, so here, we’ll go over the three types of printers (e.g., printer technologies) that are used most for 3D printing architecture models.

Fused Deposition Modeling (FDM)

A wide range of affordable FDM printers, which use a roll of filament extruded through a nozzle, are popular for in-house 3D printing. The main benefit of FDM printing – apart from its low price – is the ability to interchange the plastic filaments to produce models or model parts in a variety of colors and material properties – although it’s only possible to print with one or two types of filament at a time.

Depending on the quality (and usually the price) of your FDM printer, you may have more post-processing work to do to sand the layer lines and remove the supports to get the quality you’re looking for before painting or adding other surface finishes.

There are dual-extrusion FDM printers that extrude filament from two nozzles. This can be handy for printing the model in one material and the support structures in another, such as soluble support materials that dissolve.

Stereolithography (Resin)

Stereolithography (SLA) uses a liquid resin polymer that is cured using a UV laser. Very high levels of detail are achievable, and models are produced with smooth, durable surfaces. Some small scale desktop SLA printers are available on the market, but for full architectural designs, professional large-scale printers are more commonly used. A large build volume allows models to be produced as whole parts meaning less time spent hiding join-lines and less disruption to a model’s overall design.

As with FDM printers, you can only print in one material at a time, and there are slightly fewer material options available for resin printers than for FDM.

Color Binder Jetting

Using plastic powder as the printing materials, color binder jetting 3D printers have the ability to produce models at high levels of detail and full color without the need for supports. This method significantly reduces your post-printing labor since there’s very little to “finish” and nothing to paint. Once the excess powder is removed, the print is dipped in a stabilizing glue to seal the exterior and add a strength.

It’s an ideal choice for final architectural model presentations, such as context models and large-scale design studies.

There are color FDM printers, but for architecture models, most printing is done with color binder jetting technology or color Multi Jet Fusion technology. Some firms and model companies also choose to print with this technology in monochrome to achieve a crisp, matte finish that takes on a sculptural quality.

The downside is that color binder jetting machines and similar technology will set you back tens of thousands of dollars. Fortunately, these are the types of machines you’ll find in use at third-party 3D printing services. More on that below.

Model Post-Processing Required

For all the benefits of architectural 3D printing, in many respects it remains a labor-intensive process. All 3D printed models require a varying amount of post-production in the form of cleaning and removal of build-supports. To get the best results, a skilled and dexterous hand is needed, which is often found on anyone who considers themselves a model maker.

The majority of 3D printing produces models that are often transparent or whitish-grey in color and have the appearance of plastic. When this is not desirable, traditional model making processes, such as spray finishing and paint effects, are used to improve and elevate the visual impact of printed models.

3D printing is excellent at producing accurate, highly detailed models, but the various technologies have their own limitations. Due to the material properties of 3D printed plastics, models can sometimes be fragile. To resolve this, internal support structures can be engineered from wood or metal to provide reinforcement.

When 3D printing and traditional model making are employed correctly together, the final results can be truly stunning!

How to Print Your Own 3D Model

Before we dive into the details of how to print your own model, first ask yourself if it’s worth it to make your own models or if you should partner with a 3D printing service, many of which specialize in architecture models today.

Whether you work for a large architectural firm or an independent practice, this is a question that requires some consideration. Fundamentally, you’ll need to consider what level of investment in 3D printing equipment, knowledgeable staff, materials, and workshop space makes sense for the goals you hope to achieve.

Many of our clients have their own 3D printing capability in house, which they use for iterations, but they come to us for the final presentation model. More about 3D printing services in the section below.

In-House 3D Printed Models

No amount of drawings, blueprints, or digital 3D models can replicate the real-life perspective that you get by 3D printing your own architectural scale models. With your own 3D printer, you can test your design ideas over and over again at low cost to arrive at a final model that best meets your client’s brief.

Below we go into detail about the things to consider when printing in-house.

3D Modelling Software

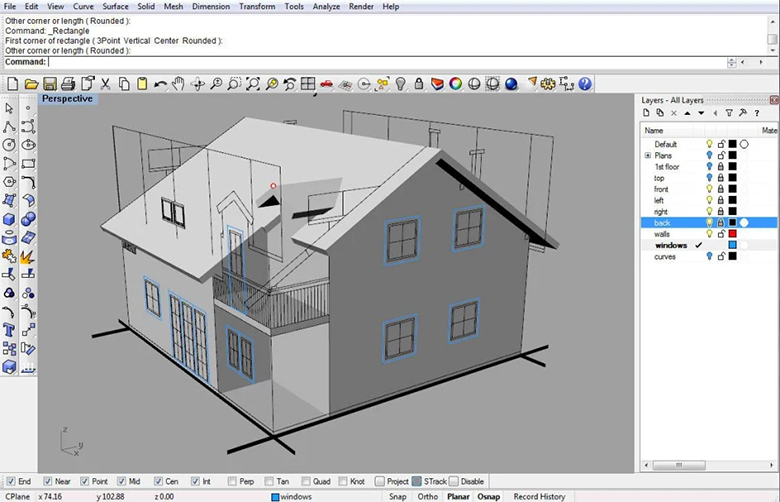

We talked about the machines above, so now let’s jump into the software. As any modern architect knows, 2D drawings and blueprints will need to be digitally recreated using 3D software before printing can even be considered. If you’re an architect, you’re probably already working with computer-aided design (CAD) software, such as AutoCAD, Rhino, or SketchUp Pro, and maybe also building information modeling software (BIM), such as Revit or MicroStation. If you’re not, check out the options in this article on architectural software.

Here at Hobs 3D we use a wide range of software but tend to use AutoCAD and Rhino most often.

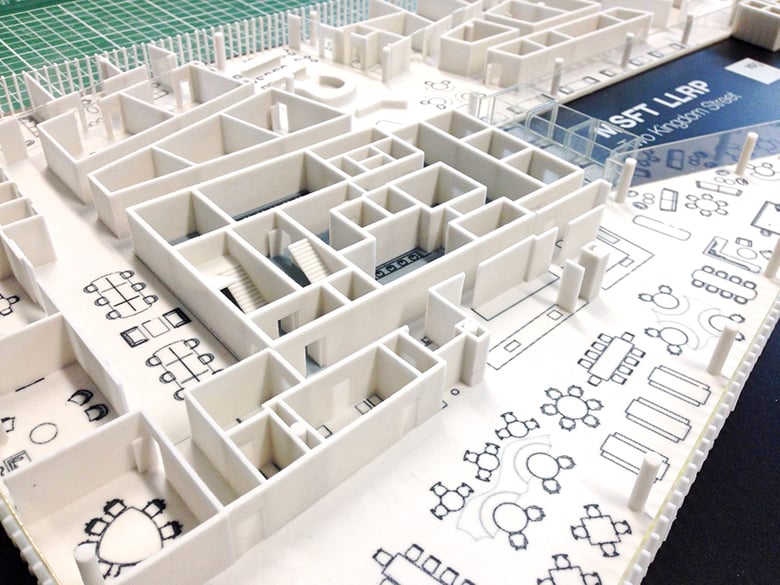

Understand that 3D Models Come in Shells

It doesn’t matter which CAD or 3D modeling application you choose, creating a 3D architecture model is almost always done by printing individual parts and assembling them. These parts, also called shells or nodes, are simply all the pieces that make up your final model. For example, your building model’s roof could be one part and you’ll print that separately. An architecture model can comprise dozens, hundreds, or even thousands of parts. You’ll assemble all of your parts to complete your final model.

These individual parts will need to be fully closed and have a suitable level of wall thickness to achieve a successful print because in 3D printing, best results are only achievable if you feed the printer watertight solid geometry. Your printer software will tell you whether or not your part is watertight and printable, but if it’s not you’ll need to repair your model, or “prepare” you model, to 3D print it.

Repairing Your Models

Most desktop 3D printers will come with their own printing software often referred to as slicing software (more below) that will automatically attempt to repair your model. If you want more control over the repairs or if your slicer software isn’t up to the tasks, there’s a wide range of software options to fix your model’s STL files.

Many, such as the one in the CAD program Blender (which is actually free) enable you to repair your STL file by choosing from a list of options that are tailored to common use cases, including architecture models or small miniatures.

For more significant problems, some professional software like Netfabb or Magics can be used to do the job for you. To move your CAD software model to your slicing software you’ll need to export the model as a STL file then upload it to the slicer.

Slicing and Supports

Once your slicing software or your file-fixing software tells you that you have a printable model, you have to consider how you will orient it in your printer for a successful print. FDM printing works with gravity to lay each layer upon the one below it. Your slicing software will automatically ‘slice’ your object into each layer that will build one upon the other. If your object has any overhangs, the software will fill in support material which can be removed at the end of the print. Ideally, you will want to create a print with as few supports as possible to reduce the labor required to remove them and sand down any loose plastic left at the end.

Another printer setting to consider is resolution. For FDM and SLA printers, high resolution prints have greater detail but take longer to print. Lower resolution prints might be all that’s required to test an idea or understand a basic shape.

Choose a 3D Printing Service Provider

If you’ve decided you want to achieve a finer finish than you’re able to do in-house, then you’ll need to find a partner that can execute your print to a high standard.

There are plenty of companies out there who offer generic 3D printing on demand, but not many of these specialize in the architectural realm. Here are the key questions we would recommend you need to ask to identify a suitable partner:

Do they offer the 3D printing technology you need?

As we’ve already written, not all 3D printing technologies are appropriate for architectural 3D printing. Large-scale SLA (resin) printing is an absolute must to achieve a top quality finish incorporating the development’s full scale. Color binder jetting printing may be desirable as well. SLS and metal are interesting but tend to be less pertinent to architectural prints.

Do They Offer a File Repair Service?

Unless you are a seasoned 3D maker yourself, your file will definitely need repairing prior to printing. Seasoned, architecture-focused 3D printing service providers will have a designated team that quickly and efficiently prepares your file for printing.

Do They Offer Professional Model Making Services?

In many cases, the print itself will not be enough. You will often require surface finishing, including painting, to give a smooth matte monochrome finish or sometimes an even higher level of craftsmanship to achieve full color, life-like finishes that resemble the final build in miniature. Specialist houses offer full model making services as a complement to their 3D printing service so you can experience a true one-stop-shop experience.

3D Printed Architecture is Here to Stay

Ultimately, any architectural project’s goal is to design and deliver an outstanding product that delights the client, builds your practice’s reputation, and helps you sell your design capabilities. 3D printing facilitates in all these ambitions and certainly provides a competitive advantage over those firms that ignore its advantages.

If you’re not already using 3D printing as a part of your design and sales processes, reach out to a potential 3D printing service provider. Then, after you’ve gained some understanding and experience of what 3D printing can do for your practice, you can then plan on bringing the process in house.

Robbie Jenkins is the production manager at Hobs 3D, a UK-based 3D solutions provider.

Lead image source: Model by 3D Hobs

License: The text of "How to Make a 3D Printed Architecture Model" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.