When it comes to empowering businesses through additive manufacturing (AM), Forward AM helps by turning customers’ design ideas into finished products.

What makes this company stand out at first glance, is the offered consultancy throughout the whole value chain and the broad material portfolio fitting all 3D printing technologies with flexible and strong materials that can withstand even demanding applications.

Established by the German chemical company BASF in 2017, Heidelberg-based Forward AM is deeply specialized in AM. With its start-up-like organizational structure of over 150 employees spread across Europe, the US, and Asia, it has a broad global presence and a strong network. By offering materials, consulting services, and post-processing solutions, it enables customers in a range of industries – including automotive, consumer, medical and dental, and aerospace – to get the most out of their AM projects.

And the company has a unique advantage – due to its ties to BASF it benefits from BASF’s research and development and knowledge of materials.

Read on to learn more about Forward AM.

AM Partner

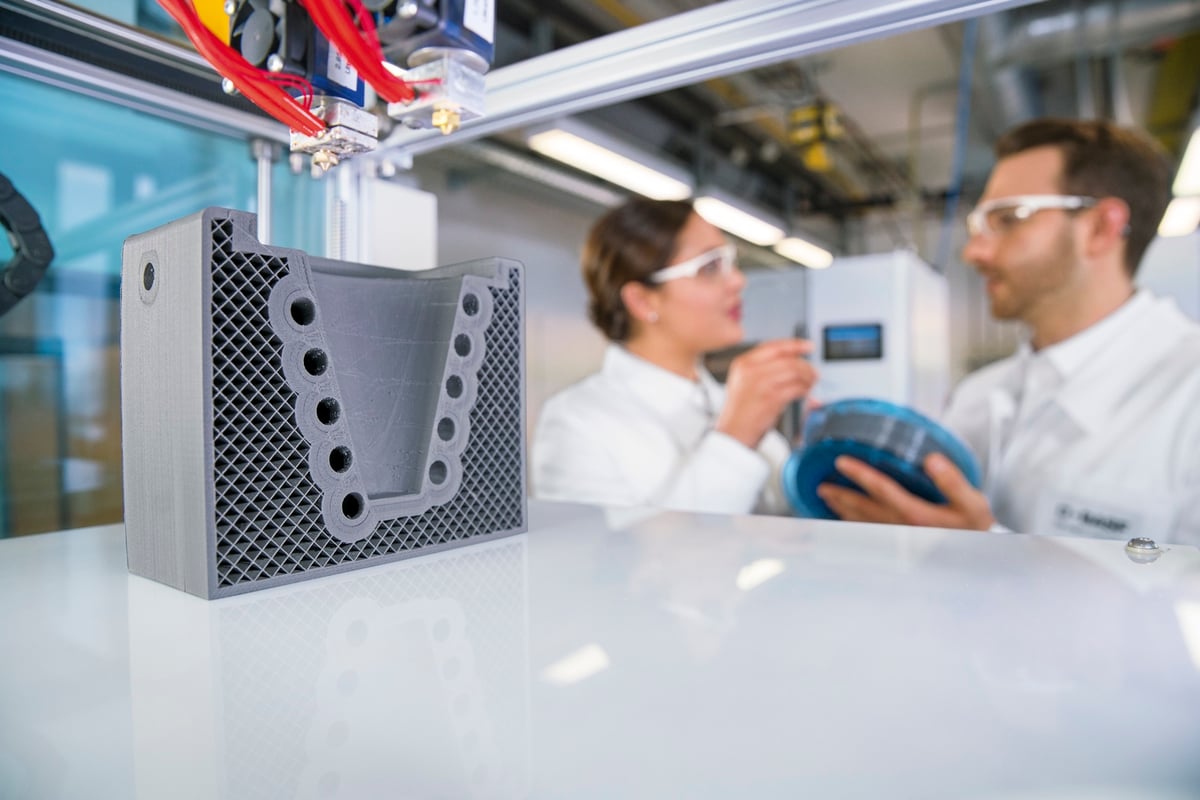

Forward AM’s proposition is that they can help customers on their AM journey from the very beginning – with a design idea – to the very end – with a finished product. Starting with the design idea, the company’s application engineers offer solutions from helping to validate and improve designs, to simulating components and process properties and spotting weaknesses in parts.

The company can recommend printing technology to optimize 3D printing processes for the best results and produce and test parts to make sure the material grade of choice qualifies for the industrial applications they’re created for.

Forward AM offers some highly specialized materials to suit the needs of its customers, including flexible materials and ones able to withstand some of the toughest applications out there.

Its Ultrafuse® TPU 85A, for example, is designed for FFF printing and is perfect for applications where flexibility is critical, like footwear, sports goods, and functional components. It also offers, Ultrasint® TPU01 for the powder bed fusion process, adapted for softer parts that need abrasive and chemical resistance, like the automotive and consumer-fashion industry. And its flexible photopolymer offering, amongst others, is Ultracur3D® FL.

Its more robust materials are Ultrasint® PA6 FR, a polymer powder which received the Blue Card certification, making it the ideal material for any applications requiring flame-retardancy, and Ultrafuse® PPSU, a filament that has flame-retardant properties and is suitable for the aerospace or rail industry.

Once the parts have been printed in the ideal material, specialists at Forward AM can then select the ideal technologies to post-process the parts to make sure they have the best surface quality while ensuring maximum functionality.

Engineering-Grade Materials

As mentioned, one of Forward AM’s advantages is that it’s a subsidiary of the chemical manufacturing company BASF. This unique position gives Forward AM special access to BASF’s R&D environment, enabling the company to build on key patents and the expertise of BASF in developing and manufacturing plastics.

It also allows Forward AM to offer one of the largest portfolios of high-performance 3D printing materials in the chemical industry worldwide, including engineering-grade materials for technologies like powder bed fusion, photopolymers, and metal and plastic filaments.

Forward AM’s materials are all manufactured with the same quality and consistency standards that BASF is known for.

Among the company’s engineering-grade materials are Ultrafuse filaments, which offer tight diameter tolerances, ease-of-use, and come in a range of types suitable for different functions including PLA, PET, ABS, HIPS, and BVOH.

Its Ultrafuse® PET CF15, for example, is a carbon fiber reinforced filament. Since it’s made of 15% carbon fibers, it allows printed parts that remain fully functional under higher mechanical and thermal loads. With its superior heat resistance, high strength and rigidity, this is a filament for a wide range of demanding industrial applications. Its high dimensional stability and very low moisture uptake make it a perfect solution for applications in humid operating environments.

Forward AM also produces Ultrasint® powders for powder bed fusion, which have the ideal properties for big lot sizes and series production. Among its Ultrasint® powders is PA6, which is ideal for applications requiring precise feature control and simple surface repossessing – perfect for complex shapes or structures. The company also offers variations of this powder, including PA6 MF, PA6 LM, and PA6 FR. Each material has different benefits which can be tailored to customers’ particular design needs.

In addition, Forward AM carries Ultrasint® PP nat 01, which offers excellent chemical resistance and high plasticity, and PA11 Black CF, which has high tensile and impact strength and yields very rigid end parts.

Forward AM also produces Ultracur3D photopolymers and inks for SLA, DLP, and PPJ – providing a diverse range of properties for AM applications, from high accuracy to improved impact strength to optimized long-term stability.

Lastly, customers can create 100% metal parts with Forward AM’s Ultrafuse metal filaments, which are designed for all FFF systems and are designed for easy and cost-effective metal part production.

Using AM to Empower Customers

All of Forward AM’s materials can be used for a range of applications, including robust functional prototypes, tools, jigs & fixtures, high-performance series parts, footwear, functional end-use parts, and fluid flow models.

By combining its access to the full spectrum of BASF’s material know-how and extensive end-to-end services portfolio, Forward AM is able to meet its customers’ requirements. In fact, the company says it prides itself on finding solutions for AM needs that are not yet met.

With Forward AM’s vast resources come possibilities to create parts in innovative ways. Find out more on Forward AM’s impact on the AM industrial revolution.

—

This content is sponsored and the views and opinions expressed within it do not necessarily reflect All3DP’s editorial stance.

For more information, please see our Terms of Use.

License: The text of "Forward AM: Portrait of an Innovative AM Company" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.