When shopping for a 3D printer that will be integrated into a classroom or professional setting, it should always meet certain prerequisites, such as accessibility and around-the-clock reliability. Of course, quality is another pertinent component to the 3D printer selection process, and finding a machine with a perfect balance of both can be quite the daunting task.

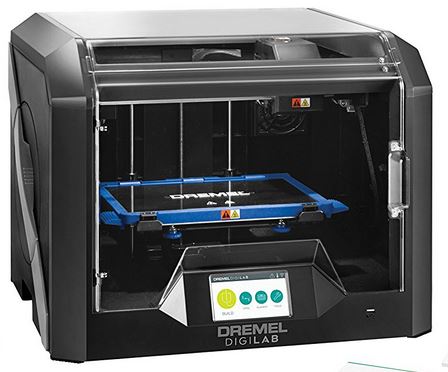

This is the space that Dremel seems to be occupying with its Dremel DigiLab 3D45 3D printer. The printer is designed to be incredibly easy to use and dependable, two critical factors for these intended markets. Priced at $1,799, this 3D printer is an affordable option for those that require safety and reliability in classroom or workshop.

Read more: Top 10: The Best 3D Printers for Schools

Want to learn more about how the Dremel DigiLab 3D45 matches up to other educationally-minded desktop 3D printers? Keep reading to find out.

Verdict

Pros

- Easy to set up and use

- Excellent print quality when using proprietary materials

- Designed to enhance safety and reliability

- Comprehensive 3D printing ecosystem tailored for education

Cons

- Reduced print quality when third-party filament is introduced

- Tends to struggle with more advanced materials like Nylon

- Closed system ensures safety and reliability, but limits creativity

Verdict

Depending on your wants and needs, the Dremel DigiLab 3D45 can either be seen as a fairly excellent or highly limited 3D printer. If you plan on staying within the Dremel ecosystem while you print, the Dremel DigiLab 3D45 is a terrific machine that promotes safety and reliability. But once you decide to stray outside of the manufacturer’s proprietary boundaries, the capability of this 3D printer takes a noticeable nosedive.

Intuitive Features for Classrooms and Professionals Alike

Before we dive into our hands-on review of the Dremel DigiLab 3D45, let’s take a quick look at the features that make this 3D printer such a popular option in the educational sector.

For starters, the Dremel DigiLab 3D45 is capable of tackling more advanced materials that require high printing temperatures, such as Nylon, polycarbonate, and EcoABS – a more environmentally friendly formulation of tradition ABS.

The 3D printer includes a heated bed and removable build platform, offering a maximum build volume of 10 x 6 x 6.7 inches. The bed leveling is semi-automatic, using a simple two-point system. This makes the leveling process extremely easy. Prompted on the 4.5-inch color IPS touchscreen, the Dremel DigiLab 3D45 shows users exactly how much each knob should be turned in order to even out the print area.

As for precision, the Dremel DigiLab 3D45 is capable of printing objects with a 50-micron resolution. In addition to the high-temperature extruder, the Dremel DigiLab 3D45 is also equipped has a full enclosure, assisting in keeping the build chamber temperature stable. Despite being encapsulated, it’s still easy to observe and tinker with the printing process. Not only is the door and lid completely transparent, but both can also be opened while the printer is in operation.

When using proprietary filament from the manufacturer, there’s an RFID reader that will automatically recognize the filament type and adjust the printer settings accordingly. This makes it easy for students and teachers to start their 3D printing projects as soon as the material is loaded. After loading the Dremel material into the internal spool holder, the machine was able to instantly detect the spool and prepare the settings for our upcoming print.

Another aspect that makes the Dremel DigiLab 3D45 ideal for the classroom is the integrated 720p camera. This allows users to monitor and control multiple machines remotely. Not only can you use the camera to watch over your prints, but you can also create time-lapse videos with the captured footage. Users can watch the printing process using the cloud-based slicer Dremel Print Cloud. We found that this camera worked relatively well, but there seemed to be a noticeable amount of lag that sometimes brought the real-time streaming to a complete halt.

The 3D printer is developed with Bosch sensor technology and UL certification, meaning that users should be able to rely on the 3D45 for safe use in learning or studio environments. There’s also carbon filters to protect from harmful VOCs and unpleasant odors.

All in all, the Dremel DigiLab 3D45 is ideal for makerspaces and classrooms. It’s easy to network and stack multiple printers with one another, creating an efficient print farm that is completely interconnected and can be controlled all from one place. Connectivity can be made via WiFi or Ethernet, as well as USB for offline printing.

When we received the Dremel DigiLab 3D45, we found most of these features to be as described. The printer is essentially plug-and-play, requiring just a few assembly steps before we got it up and running. It took about 20 minutes before we got started on our very first test print.

We found the Dremel DigiLab 3D45 to be exceptionally intuitive and easy to use, particularly when using proprietary materials. However, throughout the review process, we also encountered a few hiccups, all of which we will touch upon in the following sections.

Amplifying Advanced Materials

The Dremel DigiLab 3D45 is compatible with a range of advanced materials. Our review unit came with two spools of Dremel-branded Nylon and Eco-ABS, so we put PLA on the backburner and jumped straight into the harder-to-print materials.

As per usual, we kicked off our testing with the famous 3DBenchy model, a torture test used across the 3D printing community to see how a 3D printer performs with difficult geometries and design features. Before we could start extruding, we had to load the proprietary Eco-ABS filament into the spool holder compartment that is integrated into the side of the printer.

The filament loading process is a breeze. The spool snaps right into place and is inserted into the top of the print chamber, where there’s a filament guide clip to keep the filament in place as it’s fed into the extruder. Using the RFID chip, the Dremel DigiLab 3D45 was able to instantly recognize and prepare the printer for the Eco-ABS.

Our initial Benchy model was exceptional, we were extremely impressed by how this 3D printer was able to seamlessly print with ABS without any issues. Nearly all of the design features integrated into this little boat were flawless, from the surface overhangs to cylindrical shapes. The surface of the Benchy was incredibly smooth, perhaps due in part to the sleek black filament color, and any layering issues were hardly noticeable.

Next, we moved onto some test models that were included on the SD card that came with the Dremel DigiLab 3D45. The manufacturer included a variety of complex models for test prints, one of which was the towering Mechanic Girl. Printed again in Eco-ABS, this model includes a ton of difficult-to-print geometries and seems designed to show just what the Dremel DigiLab 3D45 is capable of.

It features a wrench-wielding maker who stands proudly atop a gear, with a ton of tools littered around her feet. Despite the many angles and overhangs, it printed nearly perfectly without any support structures. As you can see in the detailed photos below, the model of this young female maker is packed with intricate details from head to toe. Despite this, the Dremel DigiLab 3D45 was able to tackle every complexity with grace, resulting in the most impressive model we were able to achieve on this 3D printer.

With the Eco-ABS, the print quality turned out incredible, to say the least. The only issue with this print was the slight discoloration that appeared in some areas, but even this added an unexpected, but visually aesthetic effect. You’ll notice that every single detail is represented well in this test print, from the shoelaces of the boots to the model’s waving head of hair.

The next test model we loaded up was a ferocious Lion bust, yet another highly detailed design that the Dremel DigiLab 3D45 handled masterfully. Once again, the 3D printer proved adept at reproducing details like hair and facial features. The king of the jungle wears a fierce grin on its face, so you can almost hear the growl just by looking at the print. This particular test model also came out with exceptional quality. The lion’s mane seems to waver in the wind, while its intense eyes are focused on whatever prey stands before it. These are details that don’t always come through when 3D printed, but the Dremel DigiLab 3D45 proves itself capable of printing some of the most elaborate features.

Needless to say, the Dremel DigiLab 3D45 made a tremendous first impression on us. Unfortunately, when we moved onto the Dremel-branded Nylon filament, things didn’t go quite as smoothly as with the Eco-ABS. After loading up the Nylon, we set forth to print some more functional models. The manufacturer included a circular bracket with the collection of test prints, a functional prototype that seemed like a good match for the Nylon material.

Compared to the Eco-ABS, the Nylon material was much more difficult to print with. Despite being a proprietary material, we initially had trouble with getting the first layer to stick to the bed. After solving this first problem by upping the bed temperature, we finally got the test model to print.

While the quality of the Nylon print was decent in some areas of the print, the layers seemed to struggle in sticking together. The first time we tried to remove the print, it broke horizontally into two pieces. We also found that the surface layers tended to peel away from the rest of the model.

After having far less success printing with the Nylon than Eco-ABS, we suspected that the culprit that ruined the printability of this material was external moisture (which impacts Nylon much more than other materials). Regardless of the reason, we found the Nylon to be borderline unprintable due to the layering issues. Therefore, we focused more on printing with the Eco-ABS, which produced consistent and high-quality results with ease.

We also wanted to see how the Dremel DigiLab 3D45 handled third-party materials, and our results were, unfortunately, a bit of a let down.

Not All Materials Are Created Equal

We were extremely impressed with how the Dremel DigiLab 3D45 handled the EcoABS (not so much the Nylon material, though). But then again, this material is proprietary and likely optimized for this machine. While the manufacturer recommends sticking to its own filament, the DigiLab 3D45 is also compatible with third-party materials as well.

There’s no sugar-coating the limitations of proprietary-driven 3D printers. Most makers don’t want to be restricted to a few filament types. And so, we wanted to experiment with other materials to see how the Dremel DigiLab 3D45 would handle a spool of foreign filament. Unfortunately, there was a stark difference in print quality between the Dremel-branded filament and third-party materials.

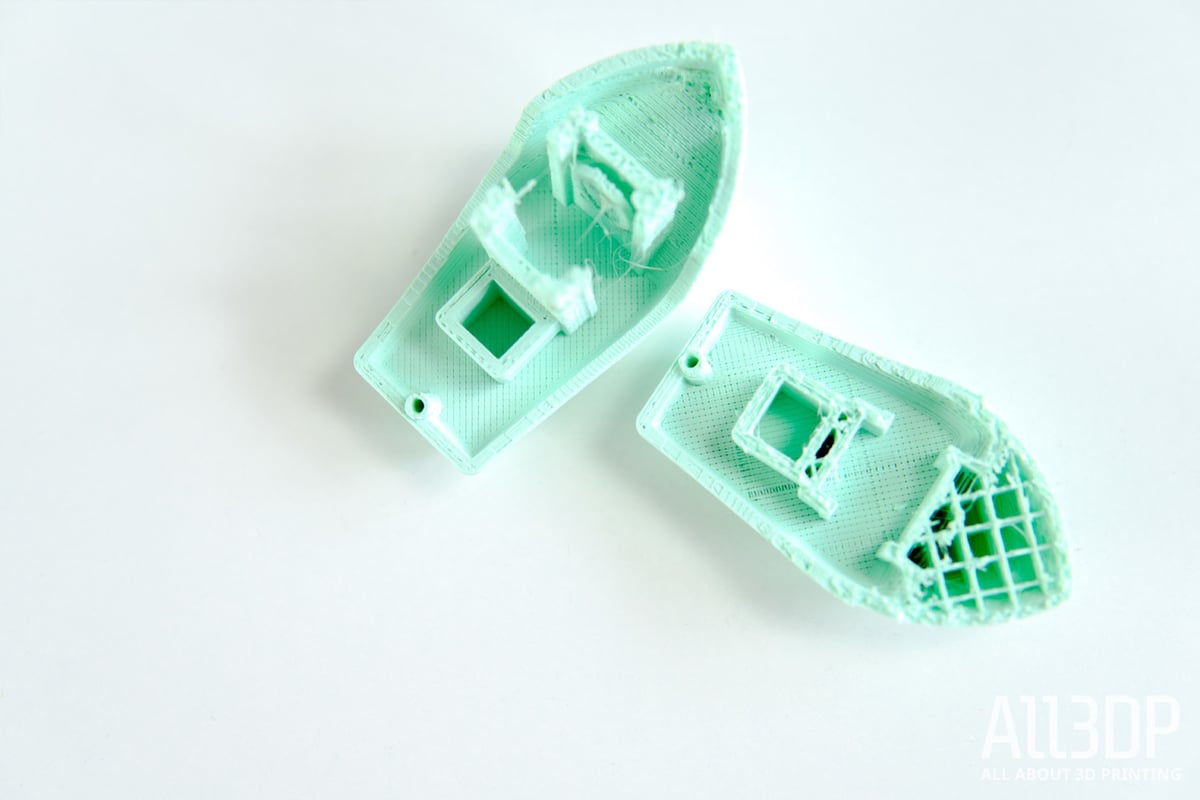

Aiming to print another 3DBenchy, we loaded some Mint colored Fillamentum Extrafill PLA into the filament pathway. Since the Dremel spools are specifically sized to fit into the 3D printer’s side compartment, most other spools need to be rigged outside of the printer before being fed into the extruder system. Although this is a minor inconvenience, we were able to resolve the issue with an external filament spool holder (we used the popular 3D printed TUSH filament spool holder).

Once the third-party filament was loaded and the proper settings were dialed in, we set off to print a 3DBenchy. At first, the quality seemed to be on par with the Benchy we printed in the Dremel ECO-ABS. However, about halfway through the print, the Dremel DigiLab 3D45 started under-extruding and even stopped printing at certain parts of the model.

This led to the creation of a Benchy that looked like it had been ship-wrecked for years, deteriorating and missing layers in various areas. At first, we suspected that the extruder was clogged, but after attempting to print a few more 3DBenchy models, we found that this problem continued to persist.

From our experience, the overall print quality took a significant dip when we switched from Dremel to third-party materials. How major of a disadvantage this is will be wholly dependant on the user. For makers that like to experiment with exotic materials, this could likely be a dealbreaker. But in the educational setting, the convenience of using proprietary materials might quell the desire to use third-party filaments.

Dremel seems to be working diligently to develop a range of materials. The manufacturer’s current range of filament includes 11 colors of PLA, PETG, Nylon, and two colors of ECO-ABS. The price per spool ranges from $29.99 to $39.99, a tad bit more expensive than your average 3D printing material.

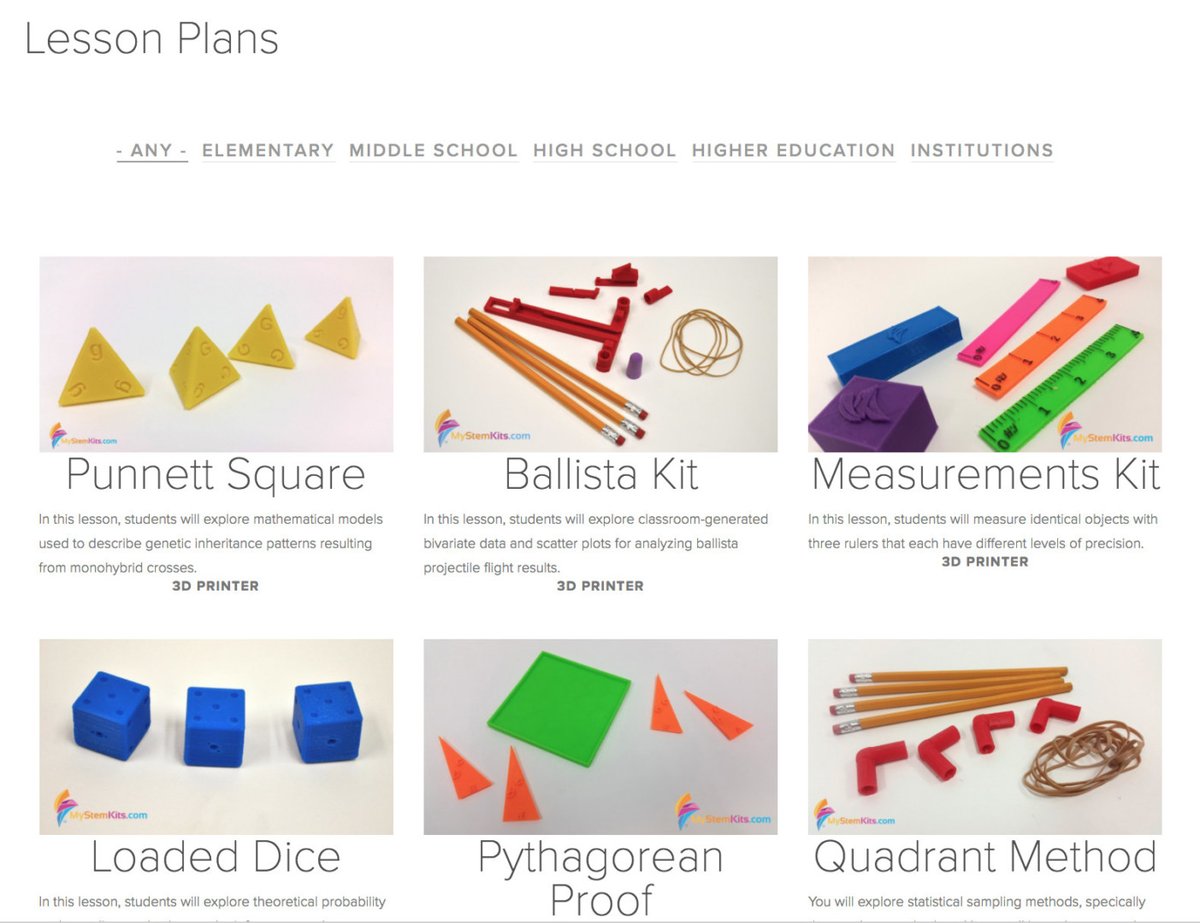

Dremel Offers an Educational Ecosystem

One of the distinct advantages that the Dremel DigiLab 3D45 holds over other 3D printers is the robust educational ecosystem that comes with it. The manufacturer has developed a curriculum for students of all ages, ranging from elementary school to the university level. From mathematical lessons to biotechnology projects, the Dremel curriculum appears to have something for every academic level. There are also other resources, such as Thingiverse, that offer free educational lessons and projects as well.

With fabrication tools that are geared toward educators, Dremel offers a collection of ready-to-use lesson plans that include various projects on STEM-based subjects. By packaging together the 3D printer, materials, and software, Dremel has created an accessible and functional workflow that is nearly perfect for the classroom setting.

The hardware itself is also optimized for use in the educational environment. The Dremel DigiLab 3D45 is designed to make setup and printing as intuitive and reliable as possible. Even younger students can follow along with the instructions for bed leveling, filament loading, and printing. The Dremel Print Cloud provides a place for teachers and students to control and monitor the entire process, ensuring that no precious time or resources are wasted.

Of course, the safety features that are integrated into the Dremel DigiLab 3D45 also make it well-suited for the classroom. The transparent lid and door allow users to get a close look at the printing action, but also keeps the heat inside and wandering fingers out. The carbon filter is also an essential part for educational use, as it keeps harmful toxins and funky odors out of the classroom or workshop.

The Final Say

In deciding whether or not the Dremel DigiLab 3D45 is the right printer for you, the answer is ultimately contingent on your experience level and how you plan to use it.

This 3D printer is a viable option for beginners looking for a simple and full-fledged 3D printing ecosystem, or for a classroom that prioritizes safety and usability above all. For an experienced maker or professional looking to experiment beyond the Dremel realm, we’d probably suggest that you look elsewhere for something more versatile machine in the same price segment.

After spending a couple of weeks with the Dremel DigiLab 3D45, we found that our personal opinion continued to waver between pleasantly surprised and sorely disappointed. The difference really came down to proprietary vs third-party materials.

When we printed with Dremel branded filament, the resulting print quality was nothing short of impeccable. But, when third-party filament entered the mix, the Dremel DigiLab 3D45 essentially became a different printer, one that was unable to procure a complete model with the desired print quality.

While we became slightly disheartened by the Dremel DigiLab 3D45’s inability to handle third-party filament, we also recognize that the manufacturer engineered this machine to work best in a closed ecosystem.

Outside of the issue with third-party materials, this 3D printer hits the mark on almost all imaginable criteria. Bed leveling, filament changing, slicing, monitoring your prints, it’s all simplified on the Dremel DigiLab 3D45. The fully enclosed print area and carbon filters also prove that user safety is a primary focal point for the manufacturer.

In order to see what the Dremel DigiLab 3D45 truly has to offer, you have to look beyond the hardware and focus on the entire 3D printing ecosystem. The Dremel Print Cloud doubles as a cloud-based slicer and 3D printer management platform, giving users full control even when they’re not right in front of the printer.

If you’re thinking about adding one to your classroom, rest assured that the manufacturer has developed a comprehensive STEM-based curriculum for both K-12 and higher education. Couple this with the convenience and protection that this printer supplies, it’s easy to see why the Dremel DigiLab 3D45 has become one of the go-to options in the educational sector.

Specs

Here are the technical specs for the Dremel Digilab 3D45 3D printer:

General

- Printing Technology: Fused Deposition Modeling

- Extruder: All-Metal Hot End/Direct Drive/Single Extruder

- Build Volume: 10 x 6 x 6.7in (402 cubic inches)

- Z-Layer Resolution: 50-300 microns

- Filament Diameter: 1.75mm

- Nozzle Diameter: 0.4mm

- Internal Storage: 8GB

- Operating Interface: 5″ full-color IPS touchscreen

- Build Platform Leveling: Semi-automated leveling

- Materials: Nylon, Eco-ABS, PLA, PETG

Temperature

- Max. Extruder Temperature: 280°C

- Max. Build Platform Temperature: 100°C

Software

- Software Bundle: Dremel DigiLab 3D Slicer (Cura), Dremel Print Cloud (3DPrinterOS)

- File Types: STL, OBJ

Electrical

- Input Rating: 100-240V, 47-60Hz, 0.85-2.3Amps

- Connectivity: Wifi, USB, Ethernet

Weight and Dimensions

- Weight: 21.5kg (47.5lb)

- Dimensions: 20.25 x 16 x 15.9in

Where to Buy

You can buy the Dremel DigiLab 3D45 from the online shops to the right. If you’re interested in purchasing multiple printers as a package deal, you can contact Dremel via their website.

License: The text of "Dremel DigiLab 3D45 Review: Best 3D Printer for Schools 2020" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.