To quote a tired meme, “Yo dawg, I heard you liked upgrades, so I put an upgrade on your upgrade”. That’s what springs to mind evaluating the Creality CR-6 SE, an upgraded Ender 3 V2 that’s so upgradey, they couldn’t even give it an Ender 3-ified name. A whole new class, this.

Flippancy aside, the CR-6 SE deserves our serious faces, because really, it’s quite a remarkable little printer the shows the kind of elevated machine a company such as Creality could be outputting on the regular. It’s not perfect, but it is exciting.

Stepping aside from the printer for a second, it launched as a Kickstarter oddity, attracting a not inconsiderable amount of ire from its crowdfunding backers and other early adopters, for reasons we’ll address a little further down this review. To many, the CR-6 SE’s name is mud, which is a shame, because it’s quite an interesting printer.

Cliffnoting the CR-6 SE, it’s a 235 x 235 x 250 mm build volume, with super interesting automatic bed leveling, dual-driven Z-axis, textured glass build plate, belt tensioners, a touchscreen UI, 32-bit board with silent stepper motor drivers, plus, as with the Ender 3 V2 before it, a handy-dandy tool tray (that we may or may not – but definitely will – put foodstuffs into again.)

Let’s jump to it.

Verdict

Pros

- Solid bed leveling (with live Z-offset)

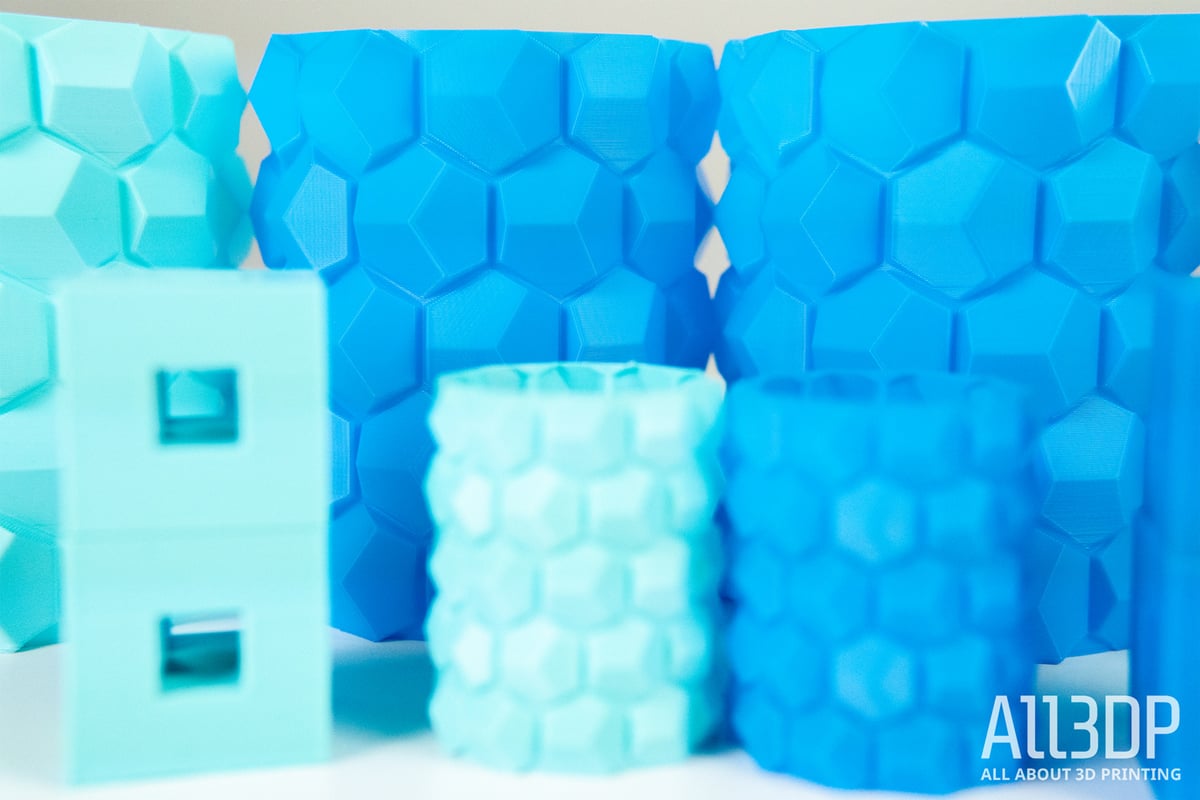

- Great out-of-the-box print quality

- Premium design, compared to past Creality printers

Cons

- Filament loading can be tricky

- Onboard settings a little sparse

- Questionable serviceability

We went hands-on with a beta unit of the CR-6 SE before the conclusion of its ~$4.5-million raising crowdfunding campaign and found that even that unfinished model presented an elevated printing experience.

Months later, and with our hands on the final, 32-bit board-toting retail version, we can say that the experience has remained pretty consistent. The CR-6 SE feels very much like the souped-up Ender 3 V2. The stock print quality is great, and both the big and small touches add up to a slightly premium-feeling version of the familiar Creality 3D printing experience.

The auto-bed leveling is consistent and performs well, the new extruder is easy to work with if a little over-engineered.

If you need a solid starter printer that prints well with little fuss, the Ender 3 V2 is still very much our recommended budget go-to. But if you want to do that in a little more comfort with less hands-on time with the printer, or enjoy owning odd and unique things, then the CR-6 SE is a justifiable upgrade.

A Rocky Road

Creality’s CR-6 SE is a bit unique. It was the company’s first printer to run through Kickstarter, using the platform as a marketing tool rather than anything true to Kickstarter’s core concept of connecting creatives with funding.

Things did not go smoothly. A long trail of dissatisfied backers can be found on the Kickstarter campaign’s comments section, with the complaints ranging from slow updates on shipping, to the alleged retail availability of the printer before all backers rewards had shipped to backers, and perhaps more pressingly, a faulty first batch of printers suffering from electrical issues frying boards and power switches (a telltale sign of the issue was, apparently, that the power switch was loose to the touch, not nested properly in the printer’s housing.)

No slight goes unpunished, though. Creality has doubtlessly lost some customers for life with the CR-6 SE’s troubled early units. The company did publicly acknowledge that there was an issue and set about rectifying it. Despite not going to the lengths of documentation that other prominent 3D printing companies have (Hi E3D) to document issues, it would seem that Creality has gotten the CR-6 SE applecart back on track.

Our review sample has a clicky, unmoving power switch and, after more than a handful of days runtime, no blue smoke or issues of note. An anecdotal sample of one, we know, but one that allows us to see what exactly this printer is all about.

Marshmallows and Bed Leveling

At first glance, the CR-6 SE looks like a souped-up Ender 3 V2 and this is not all that far from the truth. Its odd name comes from it being Creality’s 6th anniversary and an opportunity for the company to do something a little outlandish to, it claims, give back to its customers – besides a headache in warranty claims, that is. (Couldn’t resist.)

For your $399, the CR-6 SE comes with a 235 x 235 x 250 mm build volume, dual Z-axis stepper motors, a Creality 4.5.2. 32-bit mainboard with TMC2209 stepper motor drivers, a textured glass bed, X- and Y-axis belt tensioners, and a sophisticated auto-bed leveling system that, for all its complexity, works really well. This, and a double whammy of new-style hot end and extruder. Really, quite the revamp of what came before in the Ender 3 V2.

Rather than turning to the touch probe leveling used by past auto-bed leveling Creality printers, the CR-6 SE makes use of a load cell of sorts. Basically, the hot end assembly is fixed to a plate almost completely pocketed out of a larger plate, which is fixed to the print head. To determine a level, the print head lowers to the bed, meeting resistance when the nozzle comes into contact with the glass. This mechanical resistance translates to a change in electrical resistance, effectively “triggering the sensor. A mesh of these readings across the bed form the basis for a first layer that correctly accounts for any pitches in the surface. As far as we’ve seen, it’s pretty novel – pricier printers use similar systems, but we haven’t seen anything similar to this on other “budget” machines.

Theoretically, this system means you can swap nozzles, heater blocks, heat sinks…whatever, providing they fix to this plate, and continue auto-bed leveling without skipping a beat. In practice, it works very well. On no occasion did we find it failed to provide an even first layer. As with the Ender 3 V2, you can live-adjust the Z-axis, which helps to achieve the correct amount of squish.

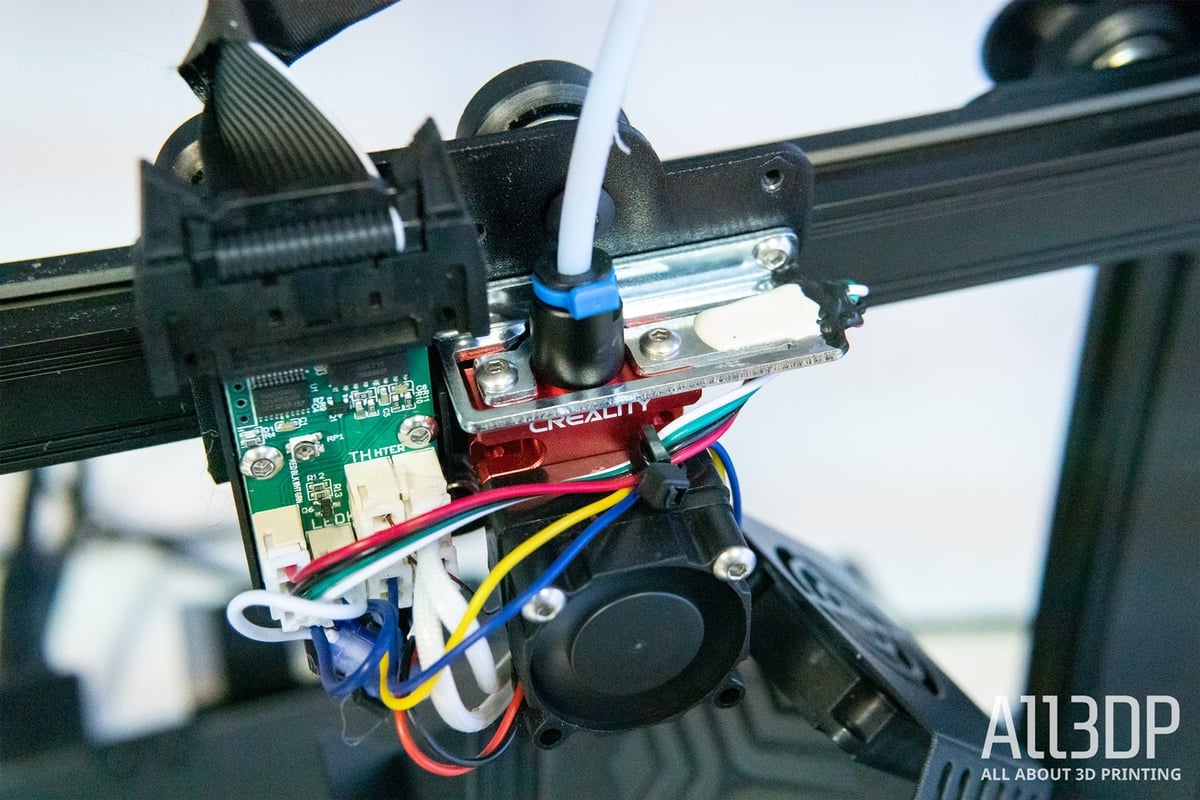

The whole print head plays into Creality’s notion of a modular hot end – one with the majority of components plugged locally into the print head and easily swappable. The implementation is neat, and we can see the benefit it might bring in servicing the printer. Whether spares will be sold preconfigured for the CR-6 SE, or you’d have to get handsy nipping cables and sleeving them in the connectors, we’ve yet to see. Creality would be missing a trick if they didn’t release high volume or high temp variants of the hot end to easily swap in.

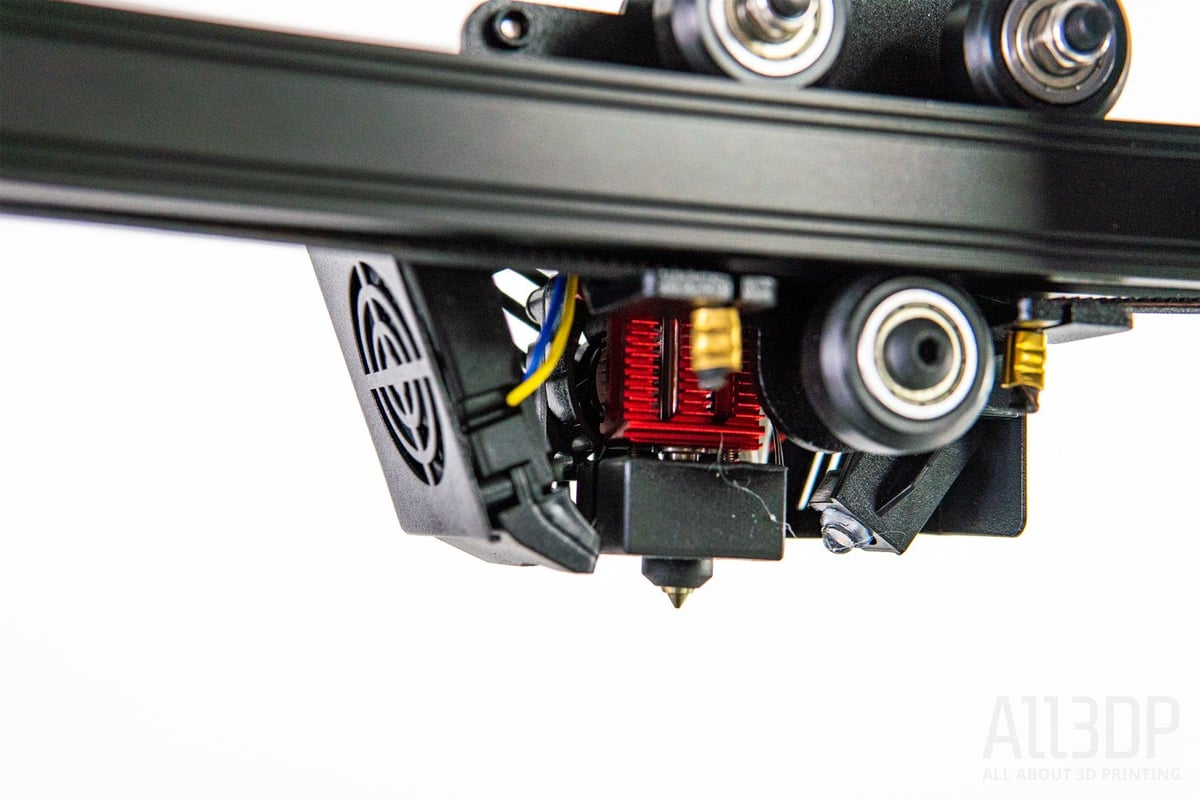

Speaking of the hot end, the CR-6 SE’s is a svelte nubbin of metal that looks incredible. Of course, this counts for nothing in its performance, but as a slim, near skeletal red strip of a heat sink leading to a square, silicone shrouded heater block, it looks neat. With screws serving as standoffs – necessary, we imagine, to protect the heatbreak from the bed leveling procedure – it bears some resemblance to Slice Engineering’s Mosquito. Lots of air gaps and a compact footprint.

One observation is that the Bowden tube sits very deep in the heatsink, butting right up on the heatbreak. Were you to print with the likes of PETG, ABS, ASA, or similar high-temp filaments, we would consider swapping the provided generic PTFE tube for a named brand you know is rated well for high temperatures.

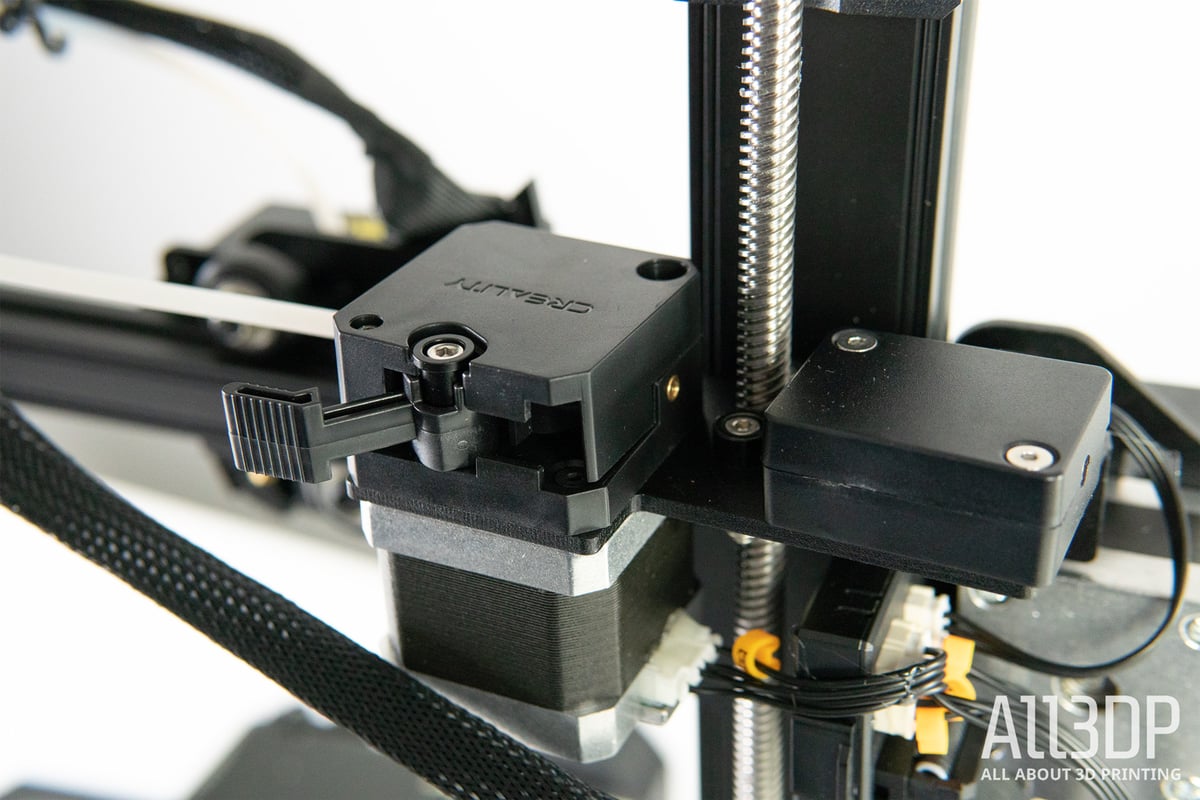

Besides bed leveling, the CR-6 SE also benefits from a new-style extruder that uses a lever action to tension the filament against the driving gear. Its novelty contributes to the CR-6 SE’s general sense of being a cut above the company’s other machines. It’s not a dual toothed gear feed though, like on the newer 3DPrintMill, but it does serve its purpose. Avoid taking it apart unless you absolutely have to. If you do, be very careful removing the housing – there are comically small pieces that will fall out and get lost in the carpet.

We’re not keen on the closed-box nature of the extruder, nor the frankly obnoxious placement of the filament sensor, which leaves you with little room to maneuver. Only the straightest filament makes it through both without catching or needing awkward intervention.

Interacting with the CR-6 SE is handled via a responsive color touchscreen, with Creality’s skin over the Marlin firmware. Similar in most ways to that on the Ender 3 V2, there are some small changes to accommodate the change in features, such as an auto-level button. You get a little less live print information on the CR-6 SE than you do the Ender 3 V2, which is an odd step backward. Something we’d expect to be rectified in a firmware update.

In practice, this touchscreen is a pleasant way to interact with the printer, responding to your touch in an instant. We don’t miss the imprecision of a rotary encoder, that’s for sure. Running the CR-6 SE and Ender 3 V2 side by side for some comparison prints left us preferring setting prints up on the CR-6 SE, simply for how much quicker it is to tap through the menus.

Further pleasantness marking the CR-6 SE apart is its use of a full-size SD card, which gives an obvious benefit if you’ve ever dropped a microSD card on a dark carpet and have anything short of eagle-like vision. Also, belt tensioners on the X- and Y-axes, a tool drawer (unlike the Ender 3 V2, with the tools actually inside it,) and dual stepper motors driving the Z-axis.

Our CR-6 SE shipped with a slightly out of date version of Creality’s Creality Slicer software (a Creality-skinned and customized version of Cura.) This software, out of the box, has a printer profile for the CR-6 SE but misses print quality profiles – a key feature of Cura – making the software experience untidy and not particularly easy if you’re not already familiar with Cura.

However, downloading the latest version of Creality Slicer adds print quality profiles (yay) but omits an obvious printer profile for the CR-6 SE (nay.) We say obvious because really, it is there, just labeled simply as the “CR-6”, which makes for a rather unhelpful time of getting acquainted with the software. This really is the last frontier for these cheaper 3D printers – a cohesive software experience. We’re not currently there yet, apparently.

On the other hand, being a peppier-looking Cura, Creality Slicer is pleasant to look at and, while missing the broad selection of material profiles and quality profiles stock Cura carries, is as capable as stock Cura for those familiar with it.

Is It Worth It?

Kinda. The bottom line is your printing won’t be any better than that found with the Ender 3 V2.

But, using the CR-6 SE for the better part of a few weeks has been quite instructive for us. You really do get the sense of it being a printer pushing to break new ground in some way. But this doesn’t escape the fact that it’s still just a souped-up Ender 3 V2. The printing performance is on par with that printer.

On the flip side, the bed leveling system is *insert chef’s kiss gif here*. There are no bed leveling knobs present on the CR-6 SE, and we’re so glad for it. Manual bed leveling sucks, and the less time we have to spend doing it, the happier we are – so full credit to the CR-6 SE for that. Similarly, using a touchscreen to manipulate the printer feels current, easy, second nature. It stands to reason that it feels right since most of us spend our days thumbing through our smartphones. It’s quick, quiet, has exotics parts that are fun to poke around and explore.

For this novelty in its custom parts, an immensely satisfying bed leveling system (for a sub-$400 printer,) and a printing experience on part with an Ender 3 V2, it makes a good case for itself. It’s a bit like a sports car, in that it still gets you from A-B, and is enjoyably special in the here and now. But only longer-term use will tell if those unusual parts can hack the long-haul, or if you’ll end up modding it sideways with more familiar components.

Features

Sleek Design & Easy Setup

The CR-6 SE has a stylish appearance sprinkled with some useful features. Embedded in the base, you’ll find a little compartment for storing nozzles, needles, pliers, and other tools. The handle on the gantry enables you to carry the printer around safely without the risk of offsetting belts or tensioners.

The printer itself comes assembled and should be ready out of the box within minutes. Just connect the gantry to the base with four screws, and you are ready to print.

Innovative Bed-Leveling

Probably the most noteworthy feature on the Creality CR-6 SE is the automatic platform leveling. Where on most Creality 3D printers you would have to make do with manually leveling via a sheet of paper, the force-based sensor on the CR-6 SE promises hassle-free automatic bed leveling. Having a truly leveled print surface greatly improves bed adhesion and print quality overall, with much less hassle.

Tempered Glass Plate

The Creality CR-6 SE comes with a carborundum glass plate as its build platform – Creality’s take on the popular Anycubic Ultrabase. The glass print bed seems to improve overall material adhesion, reduce the need for adhesives, provide a smooth surface, and let you remove prints easily once cool, something we confirmed during our testing.

Rigid Build

A recurring issue with fused deposition modeling (FDM) 3D printers is inconsistency on the surface of prints. The CR-6 SE features dual lead screws, which, in combination with the printer’s sturdy aluminum frame, can help to reduce vibrations, and therefore reduce Z-wobble giving a smoother finish of prints. The connector belt on top of the Z-axis should ensure synchronized movement. All of this results in better quality, even towards the top of the build volume.

Under the Hood

The CR-6 SE is outfitted with a 32-bit Crealtiy 4.5.2 silent motherboard and an ATmega2560 control chip, which contributes to smooth operation and thermal equality when printing. In combination with the powerful 24V 350W MeanWell power supply, the CR-6 SE heats quickly and operates at a low noise level of around 30 decibels.

Touchscreen

The CR-6 SE features a large, portrait-oriented color touchscreen with a bold user interface. Using the printer should be a piece of cake for those of us blessed with large digits on our hands. The UI is, generally, a breeze to navigate and presented us with no issues.

Further Features

Additional features on the Creality CR-6 SE include:

- Modular nozzle: Creality designed the hot end with modularity in mind. Users can exchange the heat block, heat sink, PTFE tube, or the nozzle tip with the included spares.

- Extruder: The redesigned extruder allows for straightforward feeding of filament.

- Filament sensor: The CR-6 SE has a photoelectric filament sensor detecting any possible filament breakage or runout.

- Resume print function: Outages or disconnections should be no problem for CR-6 SE because it can fully recover and resume the print when it’s back up. We confirmed this feature while testing.

- TMC2209 motor drivers: Another stretch goal, passed at the $3-million mark. The addition of TMC2209 motor drivers makes for more precise and quiet printing.

- Mean Well power supply: Clarified in a Kickstarter update, the CR-6 SE ships with a high-quality Mean Well power supply.

Max It Out

With the suggestion having gained a massive amount of popularity among backers, Creality added a brand-new CR-6 Max variant of the SE to its Kickstarter campaign just five days before its close.

Boasting a massive 400 x 400 x 400 mm build area, Z-axis supports, and all of the add-on features unlocked through the stretch goals of the campaign, the CR-6 Max is lining up to be a heavy hitter (although Creality notes the exact features may change during further development).

Tech Specs

General Specifications

- Technology: Fused deposition modeling (FDM)

- Year: 2020

- Assembly: Partially assembled

- Mechanical arrangement: Cartesian XZ-head

- Manufacturer: Creality

3D Printer Properties

- Build volume: 235 x 235 x 250 mm

- Feeder system: Bowden

- Print head: Single nozzle

- Nozzle size: 0.4 mm

- Max. hot end temperature: 260 ℃

- Max. heated bed temperature: 110 ℃

- Print bed material: Glass

- Frame: Aluminum

- Bed leveling: Automatic

- Connectivity: SD card, micro USB

- Print recovery: Yes

- Filament sensor: Yes

- Camera: No

Materials

- Filament diameter: 1.75 mm

- Third-party filament: Yes

- Filament materials: Consumer materials (PLA, ABS, PETG, flexibles)

Software

- Recommended slicer: Creality Slicer, Cura, Simplify3D, Repetier-Host

- Operating system: Windows, Mac OSX

- File types: STL, OBJ, AMF

Dimensions and Weight

- Frame dimensions: 442 x 462 x 540 mm

- Weight: 9.5 kg

Similar Printers

You may also be interested in the following printers:

For further information, feel free to check out our Best Budget 3D Printers Guide.

Artillery Sidewinder X1

The Sidewinder X1 is Artillery’s flagship 3D printer. Priced around $450, the Sidewinder puts out a similar sleek look but features a bigger build volume of 300 x 300 x 400 mm as well as a direct drive system.

Anycubic Mega X

The Mega X from Anycubic offers a print volume of 300 x 300 x 305 mm encompassed in a sturdy all-metal frame. With a fast heating Ultrabase print bed and Titan-style Bowden extruder, the Mega X is capable of printing with many different materials.

Creality Ender 3 V2

The Ender 3 V2 is Creality’s newest iteration of its immensely popular Ender 3 series. It features a slightly smaller print volume ( 220 x 220 x250 mm) and has to be leveled manually.

License: The text of "Creality CR-6 SE Review: Flight of Fancy" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.