In the years since releasing its trailblazing CR-10 in 2017, Creality has released a lot of variants in an attempt to bottle lightning a second time with follow-ups such as the Creality CR-10S and Creality CR-10S Pro.

Such was the mark it made that now, in 2020, it is still an oft-copied design in the 3D printing cosmos.

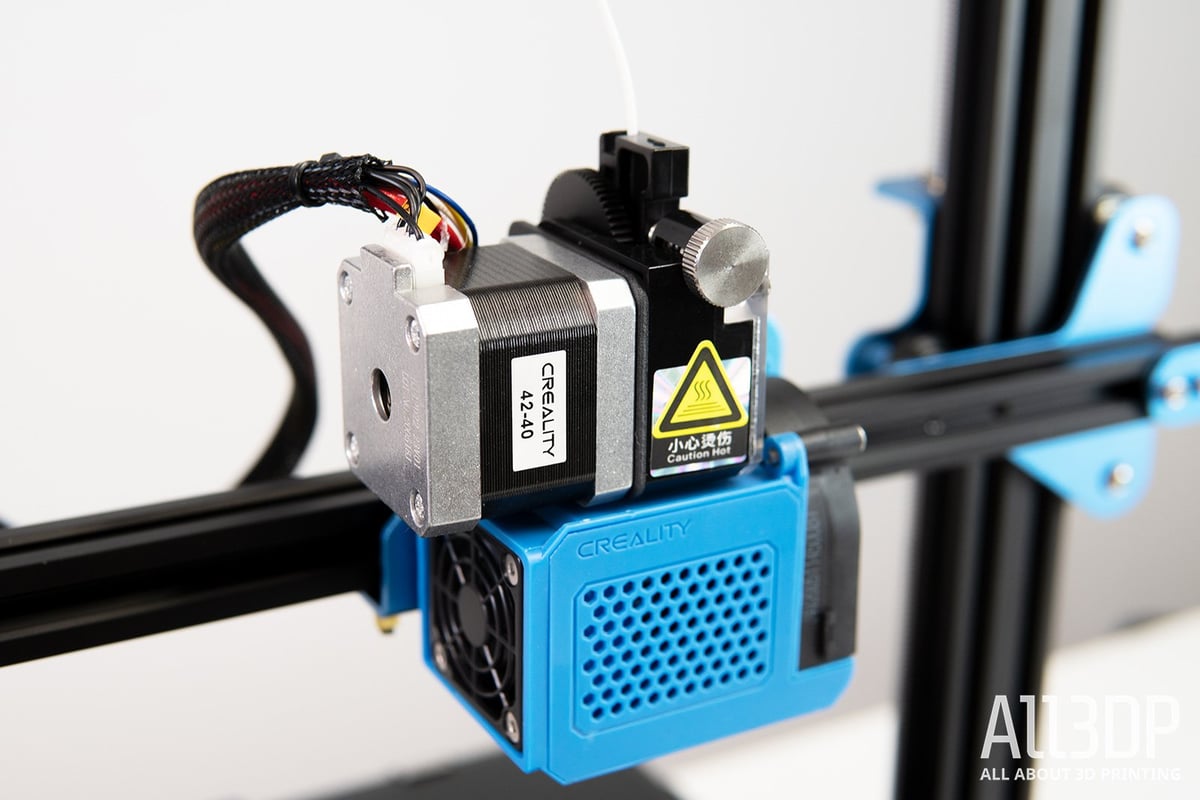

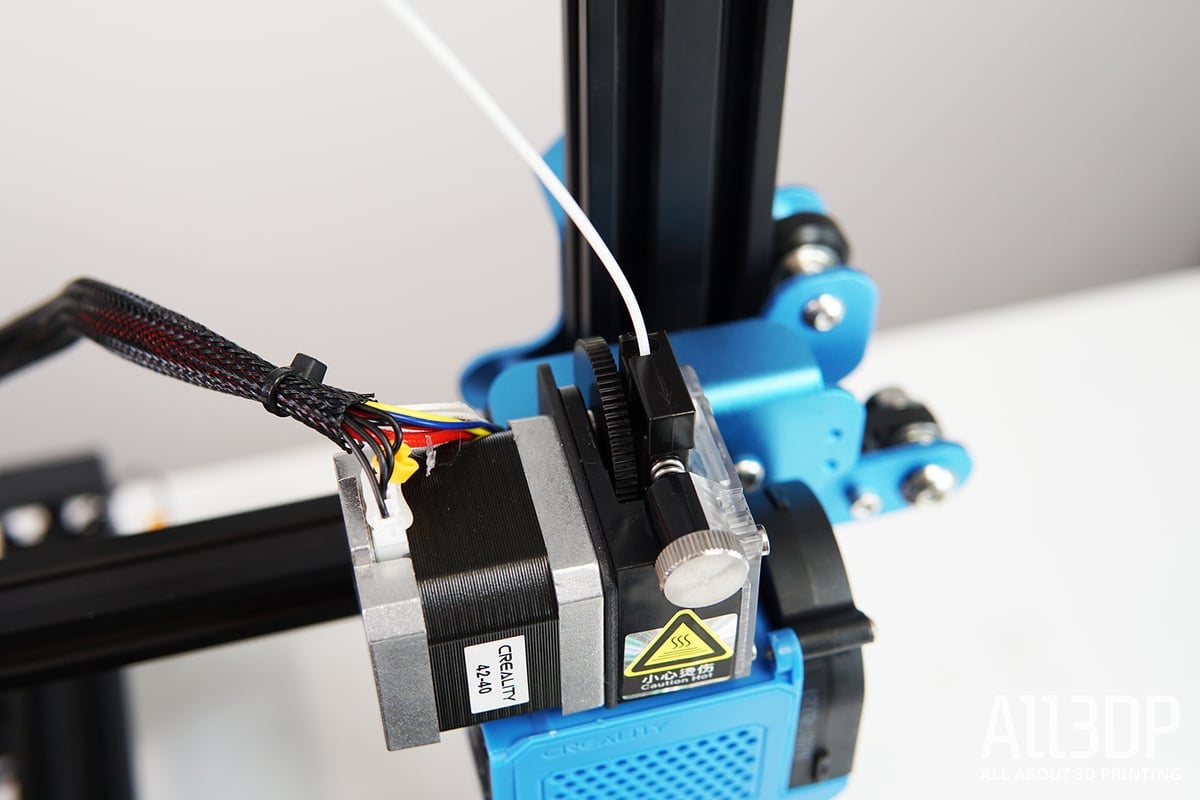

Less than two years later the much-awaited and completely overhauled Creality CR-10 V2 dropped. And now less than a year after that comes the Creality CR-10 V3. A moderately tweaked iteration of an iteration, the CR-10 V3 has one key thing that sets it apart – a direct drive extruder.

So what’s Creality playing at? Is the CR-10 V3 even necessary? We went hands-on to find out.

Hands On

Direct drive extruders are typically scarce on budget 3D printers. Recently, Artillery achieved considerable success with its direct-drive-featuring Sidewinder X1, ever so slightly tackling Creality’s hegemony over the large format budget 3D printing sector.

Can Creality, with the CR-10 V3, reassert itself?

If it ain’t broke, don’t fix it

Not to beat around the bush, but frankly, the only real change from the Creality CR-10 V2 is the switch from a Bowden extruder to a Titan direct drive, with minor changes to the spool holder and filament run-out sensor to accommodate the switch.

Having a direct drive extruder generally offers an easier time loading filament than you might have using a Bowden extruder. Also, you might see better performance when retracting filament, thanks to reduced stringing and oozing.

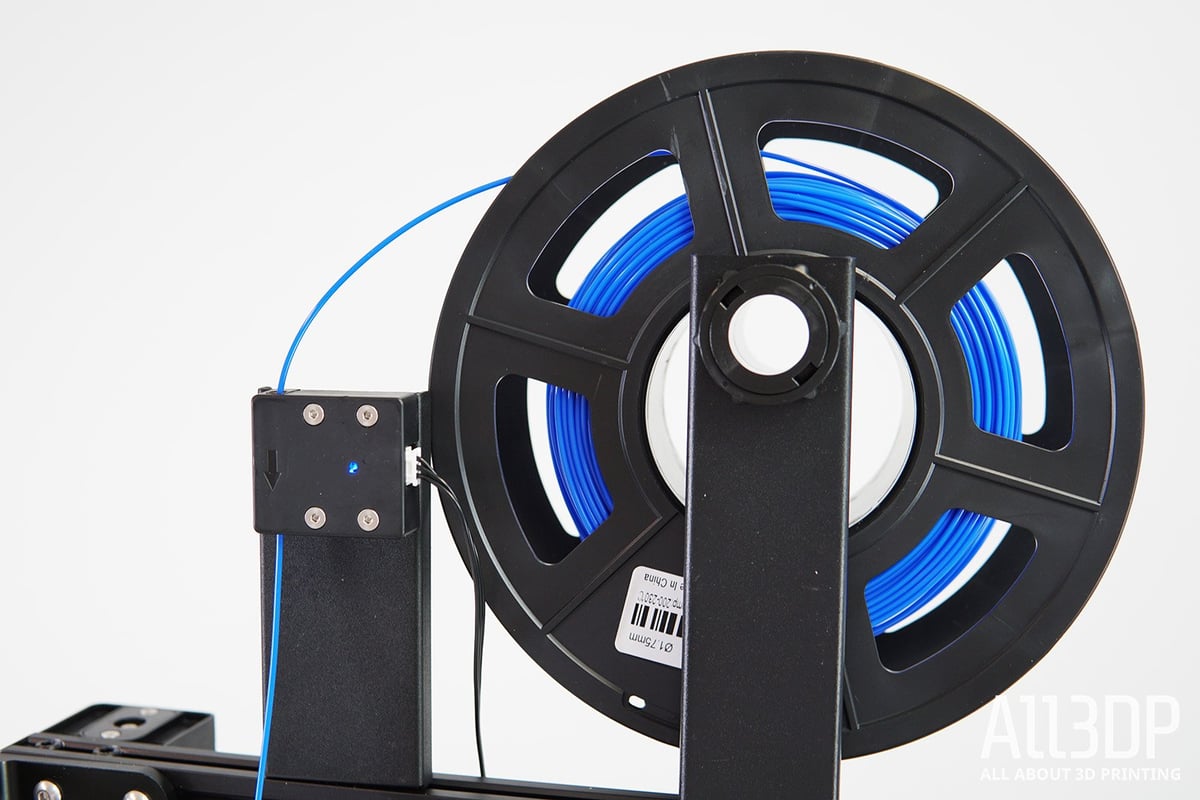

Due to the change in extruder technologies, the filament spool holder now rests atop the printer’s frame, together with the runout sensor. The arrangement means filament feeds straight down to the print head instead of sideways as would be found on the V2 with its Bowden extruder.

Placing the filament up top eliminates the issue of imbalancing the control box (a frustration of ours with spool placement on Bowden-toting CR-10 models that use the umbilical control box). It could be argued that this extra weight on the top of the frame could introduce Z-wobble in tall prints, but Creality mitigates this with a sturdy brace.

What’s more, the parallel arrangement of both holder and sensor is not ideal. Placing constant strain on the filament thread this could lead to under extrusion and prints failing, especially if the filament is not furled up properly on its spool.

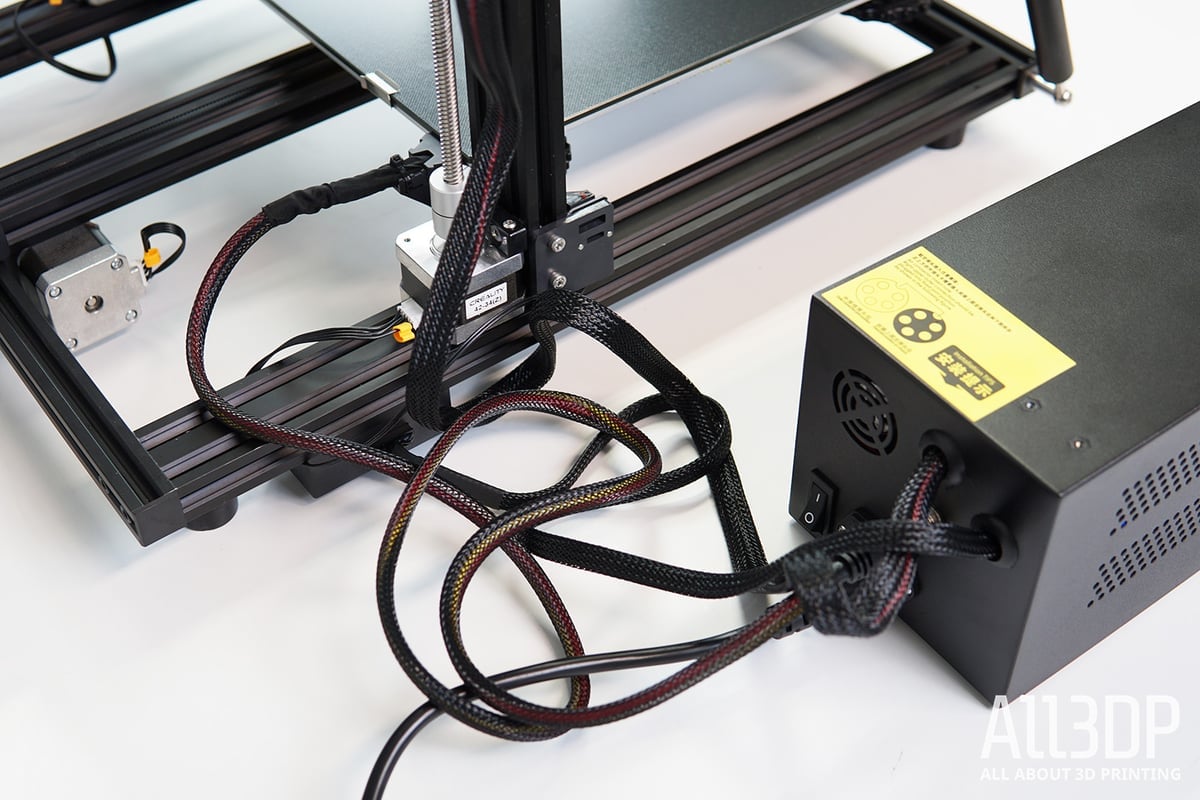

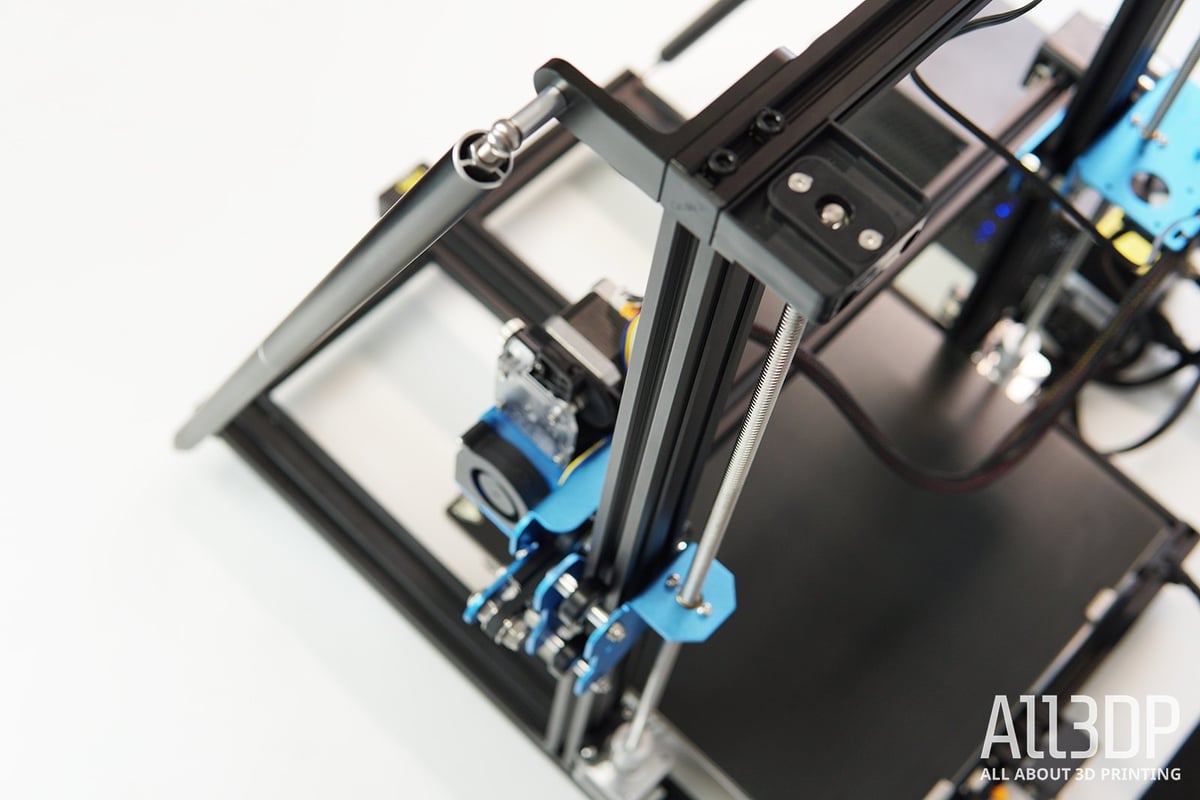

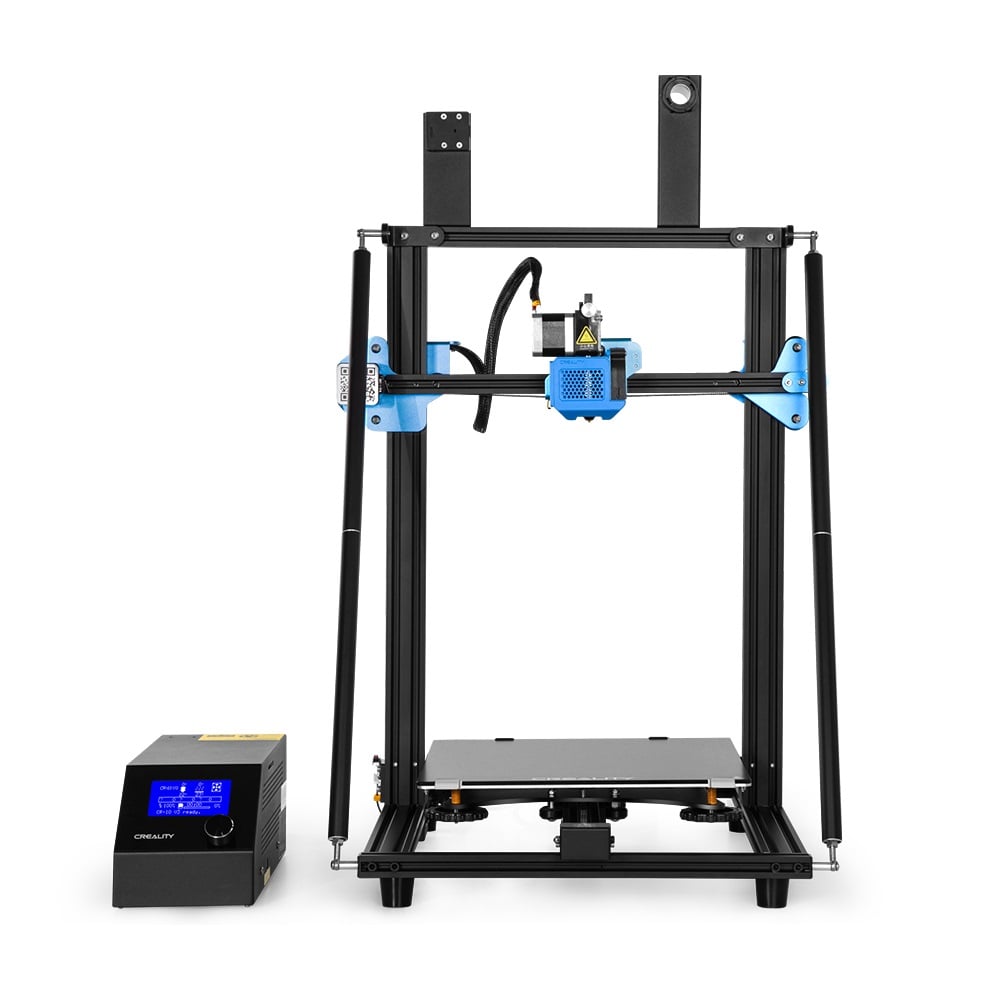

Other than that, the CR-10 V3 is identical to its forebear. It has the same Z-axis-stabilizing cross braces, sturdy aluminum-extrusion build, coated glass print bed, 300 x 300 x 400 mm build volume, and umbilically-attached control unit housing the power brick and controls.

If you already own the CR-10 V2, you can upgrade it to a V3 with the Titan direct drive extruder upgrade.

It would have been nice to see innovations found on other recent Creality printers (even some CR-series machines, such as the CR-6 SE) make it to the CR-10 V3. Be it long-term convenience of belt tensioners, automatic-bed leveling, or a slick touchscreen user interface – anything to help it stand out more.

Although Creality did furnish the CR-10 V3’s print head with space to add a BLTouch auto-bed leveling probe, it would have been nice to see the probe included as standard on the stock V3.

Another drawback of the CR-10 V3 is its umbilically-attached control unit and the mess of cables that come with it. The pause-giving frustration of correctly looming these tendrils to avoid snagging on the moving axes is practically a right of passage.

There’s a sense that the V3 is getting a bit dated. Even the budget options in Creality’s lineup (looking at you, Ender 3 V2) benefit from colorful touchscreens and easy to navigate UIs. Yet again, we wouldn’t have minded if some of the innovations would have carried over to the CR-10 V3. We don’t mind controlling the printer with a rotary knob, but the fistful of chunky spaghetti accompanying the external box sucks. Plus, the cables are quite short, restricting the box’s placement and ease of use.

Setup & Printing

After the initial assembly, the CR-10 V3’s pre-flight preparations – mainly leveling the bed – are equally effortless. However, the somewhat unwieldy user interface falls short compared to machines with colorful touchscreen UIs to tap around.

The same goes for the proprietary slicer software, Creality Slicer, which runs an old version of Cura under the hood. It does the job, but frustrations such as the software’s constant and automatic slicing whenever one variable is changed can be a drag (for you and your computer’s RAM). We recommend using a current install of Cura in the long run for better slicing performance.

Unsurprisingly, given Creality’s hot streak of decent budget printers lately, the CR-10 V3’s print quality is uniformly gratifying. It needed the bare minimum of tinkering on our end to sing.

During our time reviewing the printer, we found little to grumble about in its performance.

Detail renders well on prints of all sizes, and printing up to the full height on offer showed little sign of Z-wobble – something previous CR-10 printers without the cross brace sometimes faced.

Verdict

After printing with the Creality CR-10 V3 for a week, we can say it is definitely up to the task of high quality, day to day printing.

But (there’s always a but), given the asking price of approximately $530, and comparing it to similarly specced printers (Artillery Sidewinder X1, for example) the CR-10 V3 falls short. Be it the unwieldy control box, the somewhat outdated UI, or the noise level during operation.

Although having no real impact on the print quality, we would have expected a few quality-of-life improvements to make it to the CR-10 V3. As it stands, all Creality is offering in the CR-10 V3 is convenience. The convenience of not having to outfit a CR-10 V2 with the Titan upgrade yourself.

Thankfully, the CR-10 V3 is – as many of Creality’s printers are – a triumph in simplicity, and thanks to the massive online community Creality rallies, and common design shared by many of the company’s printers, there are numerous mods and upgrades out there that add some of what we feel is missing from the CR-10 V3.

Features

At a glance, the CR-10 V3 is the V2 with a direct drive extruder setup and new firmware – but let’s get into more detail.

Direct Drive

As already mentioned, the biggest and most noteworthy novelty is the switch from a Bowden extruder – a Creality staple – to a direct drive Titan extruder.

Having a direct drive setup does have some benefits, typically better handling of flexible filaments and better filament retraction, leading to less stringing and oozing during prints.

To help make this change, Creality moved the spool holder and filament sensor from the control box – as seen on the CR-10 V2 – to the top of the frame. Adding weight to the frame like this could contribute to instability and Z-wobble, but the support braces do well to counter this.

Sturdy Frame

Labeled by Creality as the golden triangle, and notably used in Creality’s CR-10 Max, the improved frame is not to be confused with the famous tourist area in Asia. In this case, the golden triangle refers to the Z-axis brace connecting the top of the frame to the base.

The goal of this is to give the printer a sturdier frame, reducing vibrations and Z-wobble to ensure prints have a smooth finish. From experience, we can confirm that this design helps give Z-axis consistency.

Feel the Power

Making a welcome reappearance from the V2 version is the 24 V /350 W Mean Well power supply. In the past, previous Creality printers struggled with reaching and maintaining the desired print temperatures. With the switch to the brand-name power supply, this has been tackled, allowing for a wider filament range to be processed. From our hands-on experience with the V3, the printer heats quickly and maintains a consistent temperature.

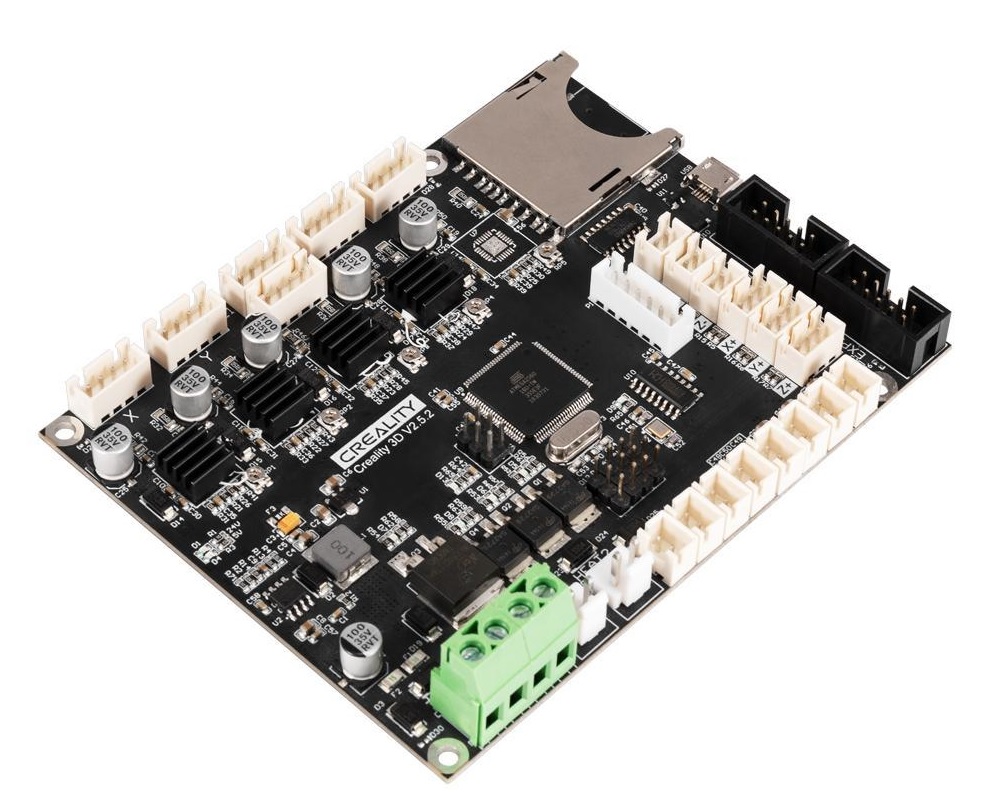

Silent Drivers

Like the CR-10 V2, the V3 is equipped with a new motherboard and a TMC 2208 ultra-mute drivers. With this silent stepper driver, the Creality CR-10 V3 is – like its predecessor – supposed to operate at under 50 decibels. We can confirm a smoother printing experience with much less motor noise during prints, but wouldn’t go as far as calling it “ultra silent.”

DIY Upgradeable

Creality deliberately left room for DIY improvements on the CR-10 V3. For the stock version, the bed leveling still has to be done manually, but the machine does feature space for a BL-Touch bed-leveling probe.

Further Features

Additional features of the Creality CR-10 V3 are:

- An Ultrabase-like build plate

- New Marlin firmware

- A resume-print function

- A filament run-out sensor

Tech Specs

GENERAL SPECS

- Technology: FDM

- Year: 2020

- Assembly: Assembled

- Mechanical arrangement: Cartesian-XZ-head

- Manufacturer: Creality

3D PRINTING PROPERTIES

- Build volume: 300 x 300 x 400 mm

- Feeder system: Direct drive

- Print head: Single nozzle

- Nozzle size: 0.4 mm

- Max. hot end temperature: 260 °C

- Max. heated bed temperature: 100 °C

- Print bed material: Carborundum glass platform

- Frame: Metal

- Bed leveling: Automatic optional

- Connectivity: SD card

- Print recovery: Yes

- Filament sensor: Yes

- Camera: No

MATERIALS:

- Filament diameter: 1.75 mm

- Third-party filament: Yes

- Filament materials: Consumer materials (PLA, ABS, PETG, TPU)

SOFTWARE:

- Recommended slicer: Cura, Simplify3D, ReptierHost

- Operating system: Windows (XP or higher), MacOSX, Linux

- File types: STL, OBJ, AMF

DIMENSIONS AND WEIGHT:

- Frame dimensions: 420 x 550 x 650 mm

- Weight: 11.5 kg

Similar Printers

You may also be interested in the following printers:

Artillery Sidewinder X1

The Artillery Sidewinder X1 and the Creality CR-10 V3 have a lot in common. They both feature a 300 x 300 x 400 mm print volume, a porous glass-coated print bed, and a direct drive extruder. The Sidewinder X1 does cost about $100 less, though.

Creality CR-10 Pro V2

The CR-10 Pro V2 costs a little extra but does have some pro features up its sleeve. For one thing, it features automatic bed leveling, and the Bowden setup is equipped with a double geared Bondtech extruder for better filament feeding.

Anycubic Mega X

The Mega X from Anycubic offers a print volume of 300 x 300 x 305 mm encompassed in a sturdy all-metal frame. With a fast heating Ultrabase print bed and Titan-style Bowden extruder, the Mega X is capable of printing with many different materials.

License: The text of "Creality CR-10 V3 Review: Hands On" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.