Creality has released some buzzworthy 3D printers over the last few years, namely in its the CR-10 and Ender series.

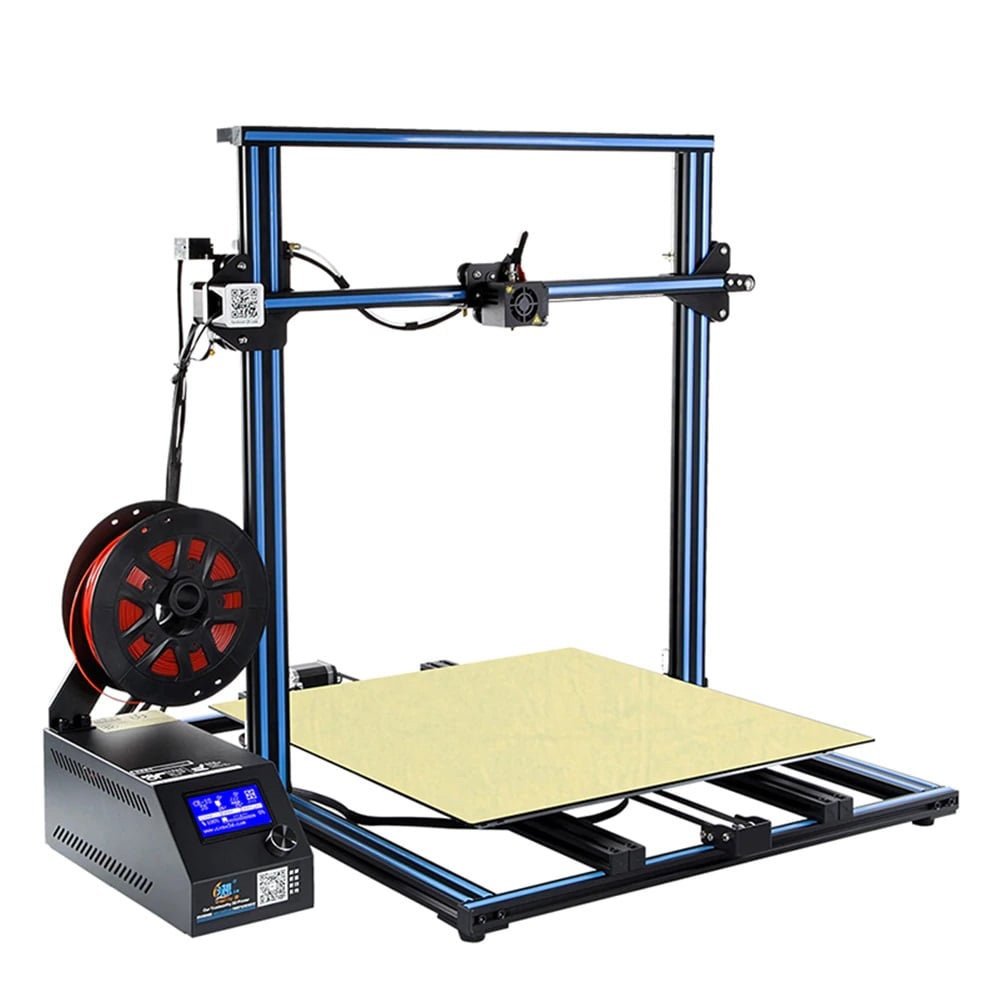

The Creality CR-10 S5 is Creality’s largest 3D printer and also one of the most competitively priced large-format consumer printers currently on the market. Packing a 500 x 500 x 500 mm build volume, it offers mind-bending possibilities for your biggest 3D printing dreams. By its scope, this 3D printer sounds beastly. But how does it fare in real-life conditions?

We have gotten ourselves a unit in the office and gone hands-on to find out.

Go Big or Go Home

Obviously, the main draw of the Creality CR-10 S5 is its ability to print enormous objects. But how well is the machine equipped for the task?

Tech up to the task?

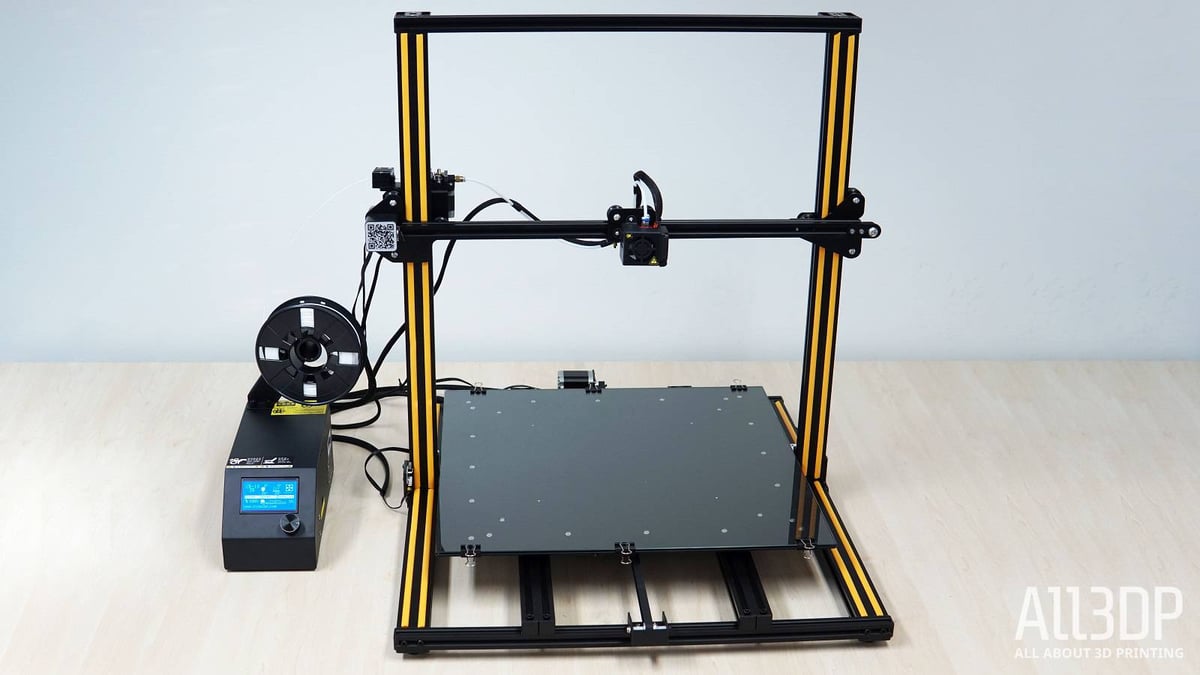

The Creality CR-10 S5 comes in the CR-series typical styling and features a dual lead screw mechanism as well as dual bed rails for smooth movement of its Y- and Z-axis parts.

Curiously, unlike other recent Creality models such as the overhauled CR-10 V2, the CR-10 S5 is missing what Creality refers to as the golden triangle – a Z-axis brace connecting the top of the gantry’s frame to the base. A measure to make the frame on its larger printers sturdier, the CR-10 S5 falls short.

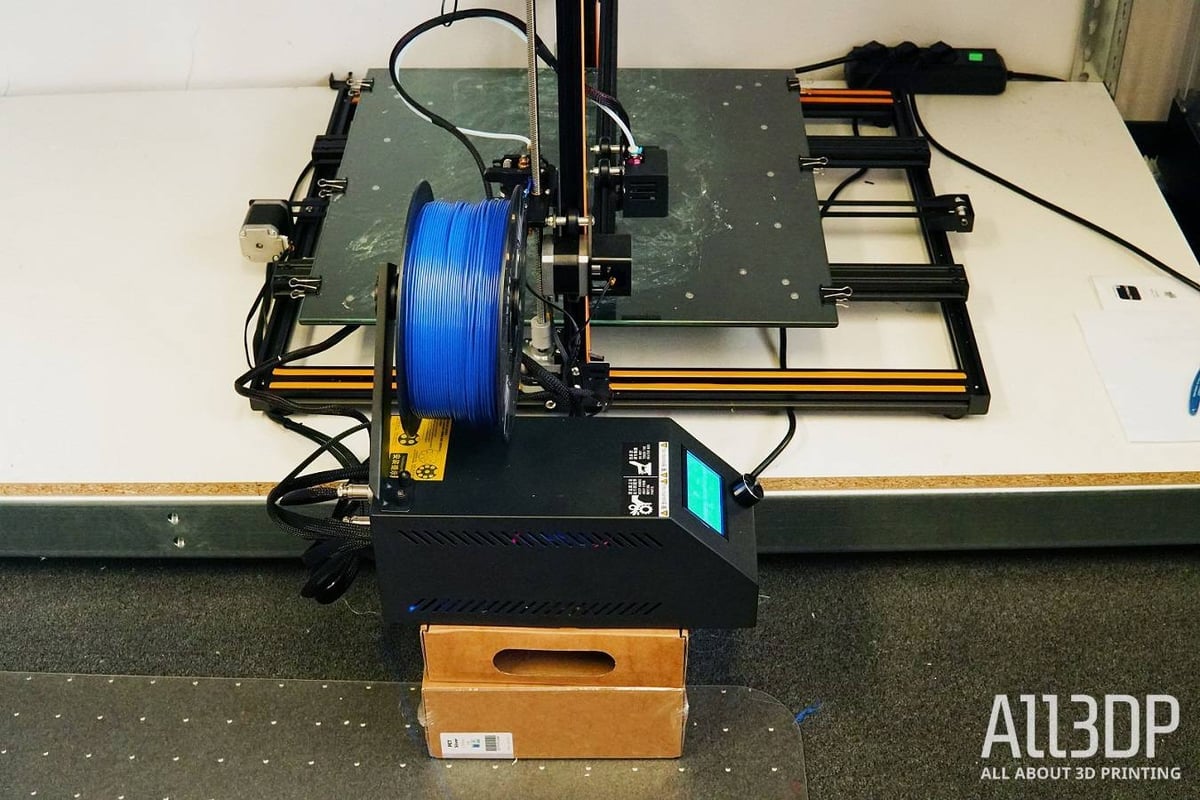

In keeping with the CR-10, which the S5 is derived from, the power brick and controls are located in an umbilically-attached control unit — the filament spool mounts on top of this box.

Having the spool holder installed separately is convenient because it would make this already enormous printer even bigger. Plus, the extra weight on the gantry could exacerbate any wobble.

The firmware and twist-to-control knob come across as somewhat outdated nowadays when you compare it to all the shiny touchscreen UI’s other 3D printers have adopted of late recently. Nonetheless, controlling the menu and printer settings is pretty straightforward. It allows you to access all the necessary settings you could ask for.

That is, if you can find a space to place the control box.

Given the printer’s size and the fact that it will be hard to find a place spacious enough to store the printer, having an external control box is a good idea as it would give you the possibility to still access the printer’s vital functions, even if the printer is stowed away in an inconvenient spot.

Or, rather, it would be a good idea, were it not for the fact that the control box is kept on a restrictively short leash – especially the X-axis cabling. Anywhere but directly next to the printer’s frame is a no-no for tall prints, with the printer unplugging its X-axis stepper motor all too easily. This makes storing this beast even more complicated, so keep in mind that you need space – and a lot of it.

The Creality CR-10 S5 has a heated glass bed that lets you operate and experiment with many material types. The heated print bed takes rather long reach the desired temperatures (to heat the bed to 80°C, slate about 30 minutes.) While this is an irritating time-drain, it is also self-evident due to the printer’s 500 x 500 mm bed size that a large plate will take longer to heat. In reality, though, the printer only heats about 300 x 300 mm of the entire bed, with a steep temperature drop at the bed’s fringes.

Especially for large prints, this may cause warping and ruin your prints before they’ve even really begun.

We tried to counter it by lowering the heated bed temperature to around 40°C when printing PLA, as to lessen the temperature differential. Especially for temperature-sensitive materials such as ABS, this might pose a problem. For our hands-on review, we stuck to printing with PLA, though, and were able to work around this issue.

Another difficulty the CR-10 S5 faces – and which plays hand in hand with the aspect mentioned above – is bed adhesion. The glass build plate, naturally, lacks the stickiness one might find with a textures sheet, something Creality tries to surpass by throwing in a roll of painters tape, which somehow would only suffice for about two-thirds of the print bed.

Ditch the tape, though, and use a glue stick instead.

Get to the task

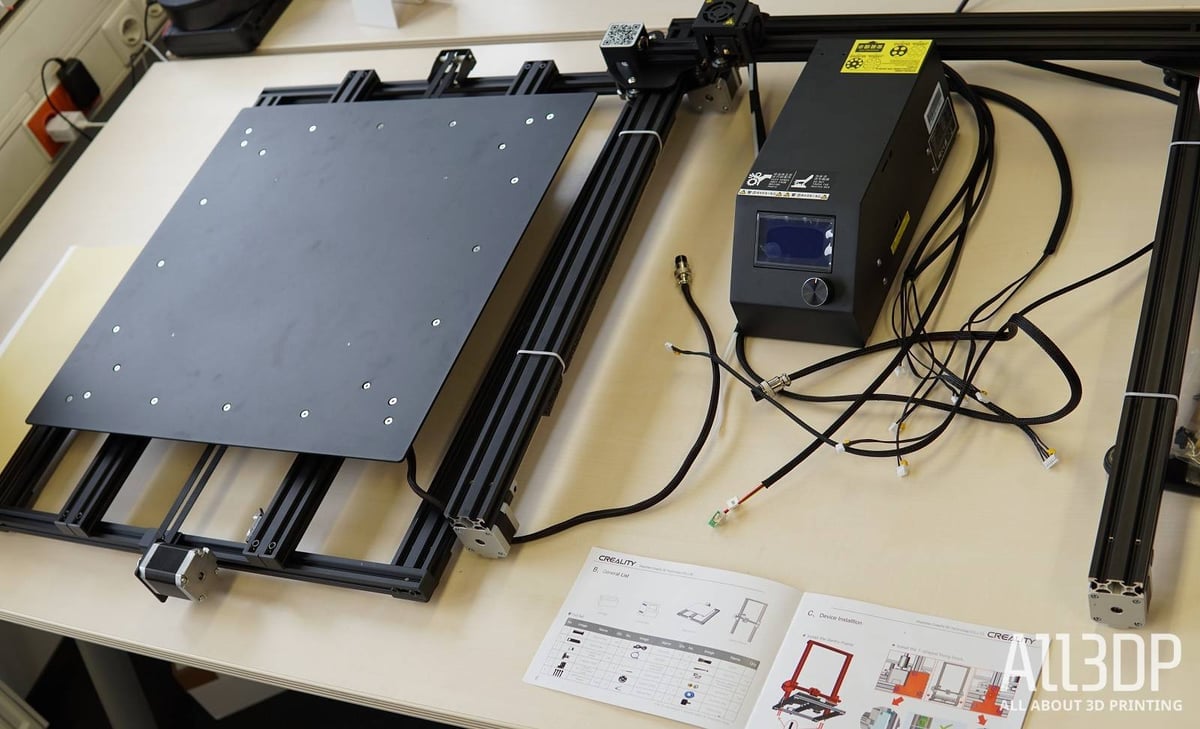

Although being marketed as a 3D printer kit, the CR-10 S5 comes semi-assembled, meaning all you have to do is to mount the Z-axis to the base, connect the cables, and you’re ready to 3D print.

If it wasn’t for leveling the bed, that is. While other CR-10 variants have upgraded bed-leveling routines assisted with the likes of BL-Touch sensors mesh-bed compensation, the CR-10 S5 still has to be leveled manually.

And honestly, it is not fun.

The CR-10 S5 uses the tiny plastic thumb nuts for raising and lowing the corners of the bed – the print bed runs too close to the frame for any large and easier to use nuts. This leaves you with no choice other than to twist and contort your wrists to reach each far-flung corner nut under the print bed. You’ll find yourself wishing for a hydraulic lift to jack it up. Lying beneath it like a mechanic would make it a breeze.

On the other hand, leveling such a big bed is rather tricky. Especially on the fringes, a perfect level is hard to attain. We did manage to level it rather quickly, within 30 minutes and the first small – and dead centered – prints came out fine.

For our test prints, we started with the go-to Benchy, or actually two versions of it. The standard and a militarized variant.

While both objects were printed without problems, you can make out some ghosting around the finer details of the boats – indicative of the resonance caused by sudden direction changes of the printers moving parts and the inertia they carry.

Even with the upgraded bearing system, physical forces can only be diminished to a certain point, which is why we would recommend to slow down the printing speed – even mid-print for larger prints – to decelerate the printer’s fast zig-zag movement.

Our next print was a screw cap bag seal mechanism. The hinges came out nicely, and all the parts fit together as they should. The printer can handle fine detail and delicate components rather well right off the bat.

But a hands-on review of a printer this size wouldn’t be complete if we didn’t go for a big print.

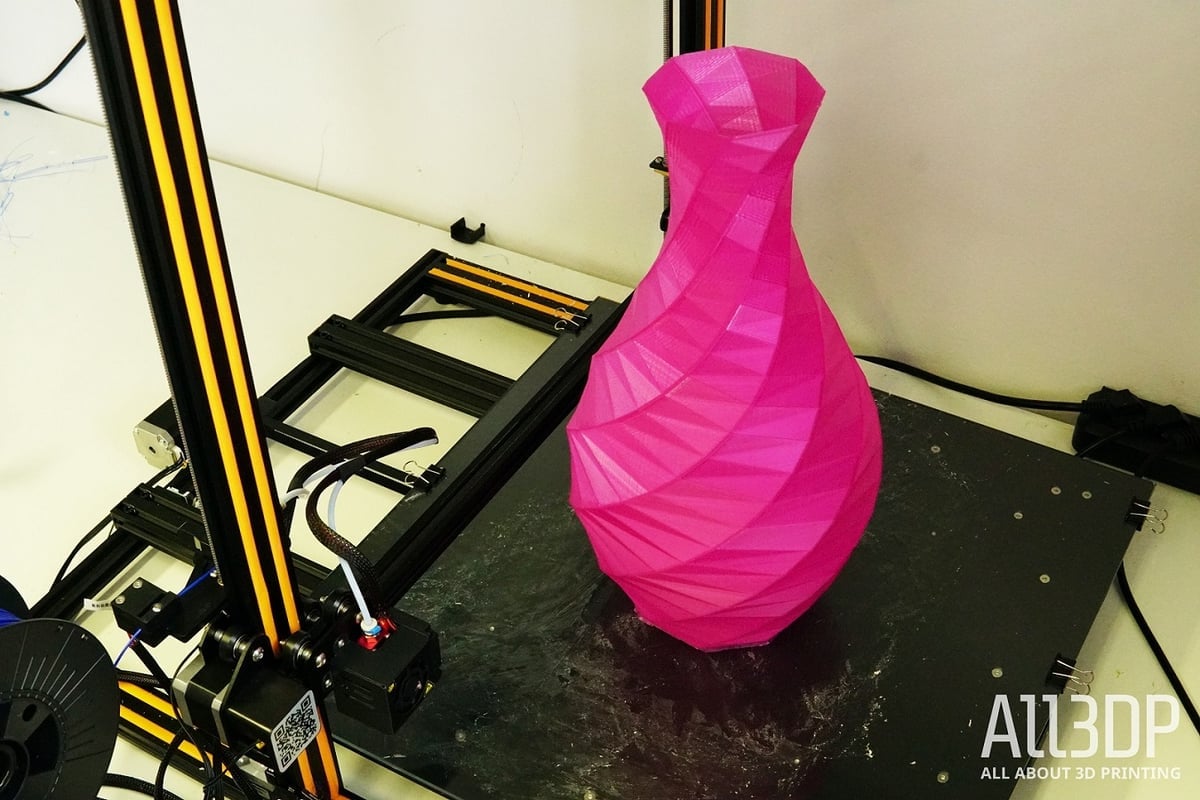

So, we went for an overnight print of an upscaled low poly vase. After one retry where the print failed about five minutes in due to adhesion problems, we came back the next morning and found quite the impressive vase.

Of course, you could go for even larger and more complicated prints, but bear in mind that this would easily lead to print times of multiple days.

If you’re interested in shortening the print time, we’d recommend swapping out the nozzle. The Cr-10 S 5 comes with an upgraded 0.4 mm MK10 nozzle. Especially for large (less detailed) prints, switching to a 0.6 mm or even 0.8 mm nozzle would increase printing speed by a lot. To further increase the volumetric throughput, you could also switch to a volcano nozzle.

Another tip – already mentioned above – would be lowering the bed temperature (when printing with PLA) to around 40°C, which will result in a better thermal equilibrium.

All in all, the Cr-10 S5 allows for a lot of 3D printing fun, but expect to fiddle around with the settings to get the best result. It is not a simple as plug and play machine – you’ll need to be aware of the printing speed, bed temperature, and retraction settings. Expect to need to tweak to get consistent results.

While we list many drawbacks above, we were positively surprised by the outcome. Being able to attain consistent results on a machine as big as the CR-10 S5 is an achievement in its own right. The sheer size and mass of the print bed alone brings a dimension of complexity to printing.

The CR-10 S5 is, arguably, a triumph in simplicity. It does just enough for the price point, and is accessible enough to lightly tweak or add wholesale improvements through numerous mods and upgrades.

To print big (and even bigger) on a budget, there are few options quite like the CR-10 S5.

Features

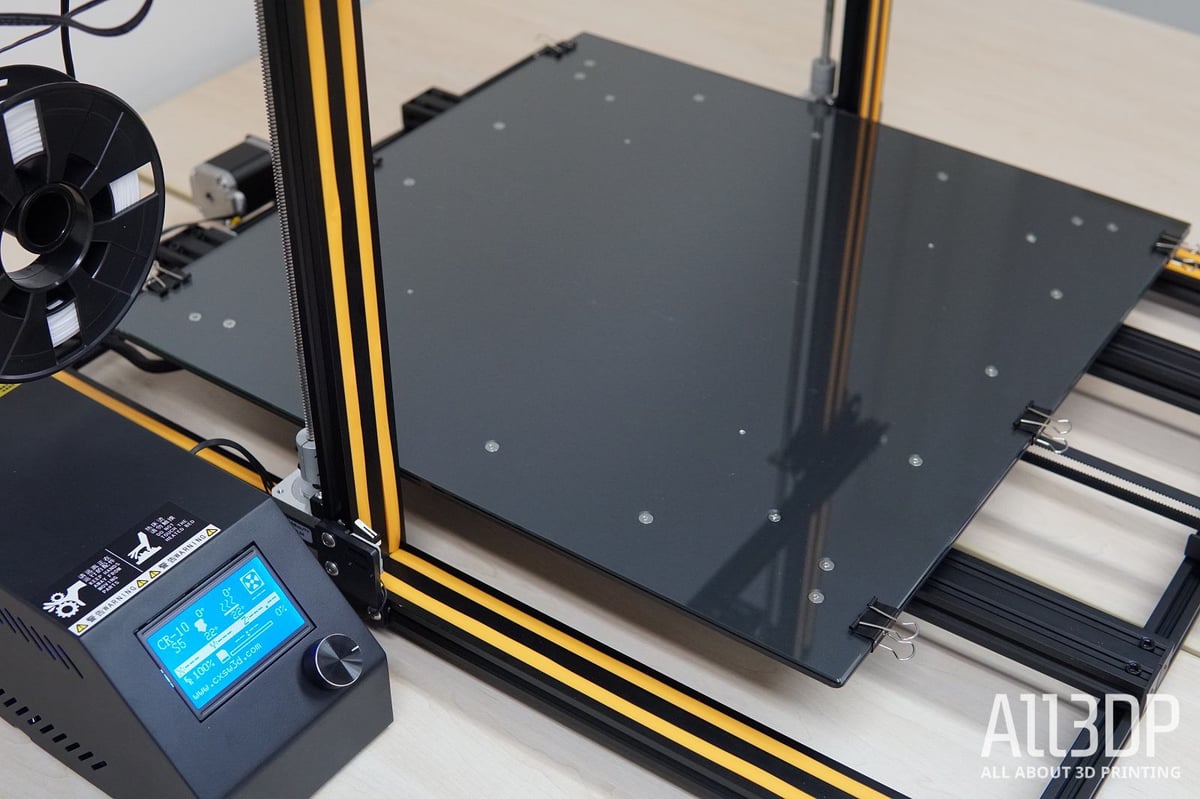

Dual Bed Rails

The most notable upgrade that hits the eye is the CR-10 S5’s enhanced bed railing system. While the older CR-10 S5 version sported only one rail, the updated version now comes with a dual bed railing system. Having to move the 500 x 500 mm heated glass build plate, a second rail leads to a more stable movement and ensure a smoother printing experience.

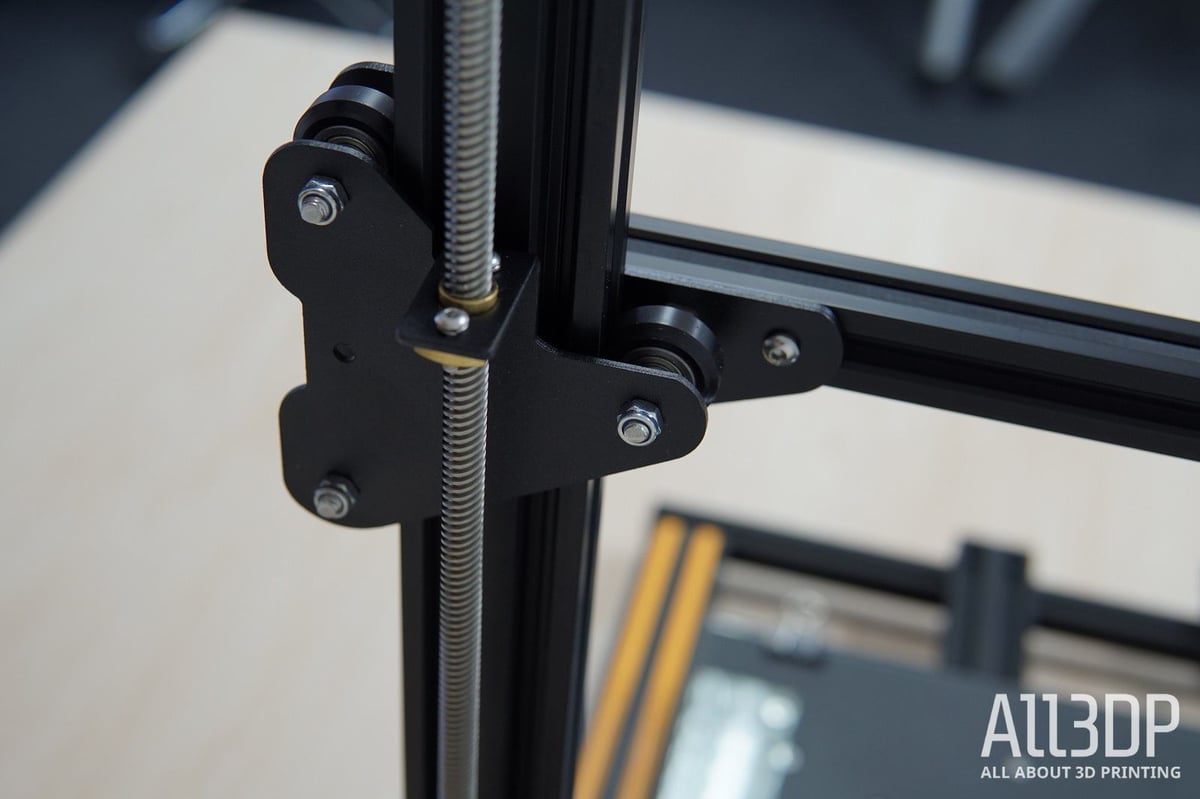

Dual Lead Screws

A recurring issue with fused deposition modeling (FDM) 3D printers is Z-wobbling due to the machine’s parts moving when operating. This can lead to unwanted layer shifting, especially when printing tall prints. The Creality CR-10 S5 is equipped with dual lead screws and two Z-axis stepper motor drivers. Combined with the printer’s sturdy aluminum frame, this feature should reduce vibrations, and therefore minimize Z-wobble, resulting in a smoother finish of prints.

While the printer still struggles with Z-wobbling from time to time, having dual lead screws most definitely helps to reduce unwanted side-effects.

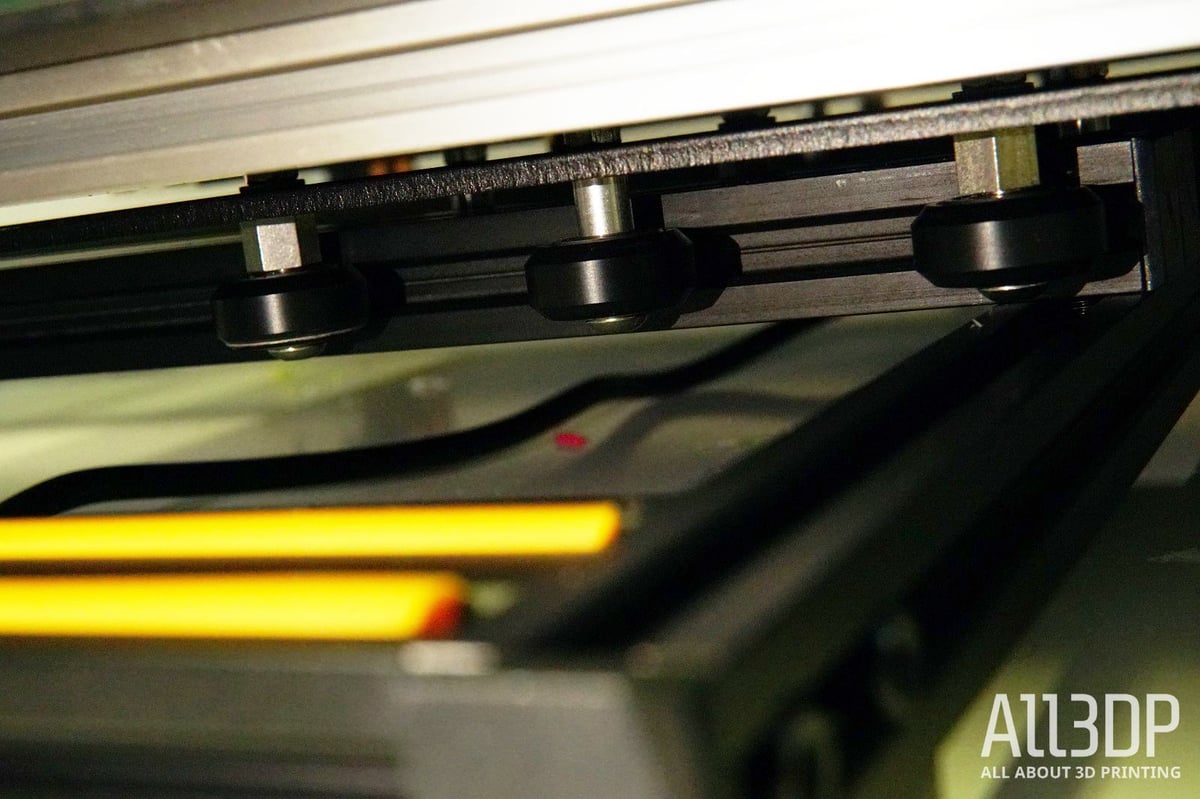

Patented Bearing System

Another feature, the CR-10 S5 spots, is the upgraded bearing system. The manufacturer even advertises it as a patented technology for the XYZ aluminum V-slot bearing. As mentioned above, a 3D printer’s printing quality is, to some extent, depending on how much the machine is bucking and jerking when running. With Creality’s high precision bearing, the printer runs more smoothly and less noisy.

New Circuit Board

An additional feature, the manufacturer advertises, is the newly upgraded industrial-grade circuit board. This should allow the printer to print stably up to 200 hours without any hiccups. Especially when considering the CR-10 S5’s build volume, long prints, lasting two to three days, can be on the agenda. And the machine should handle them without a problem. During our review, we have not come across any hiccups regarding the “brick’s” hardware.

Further Features

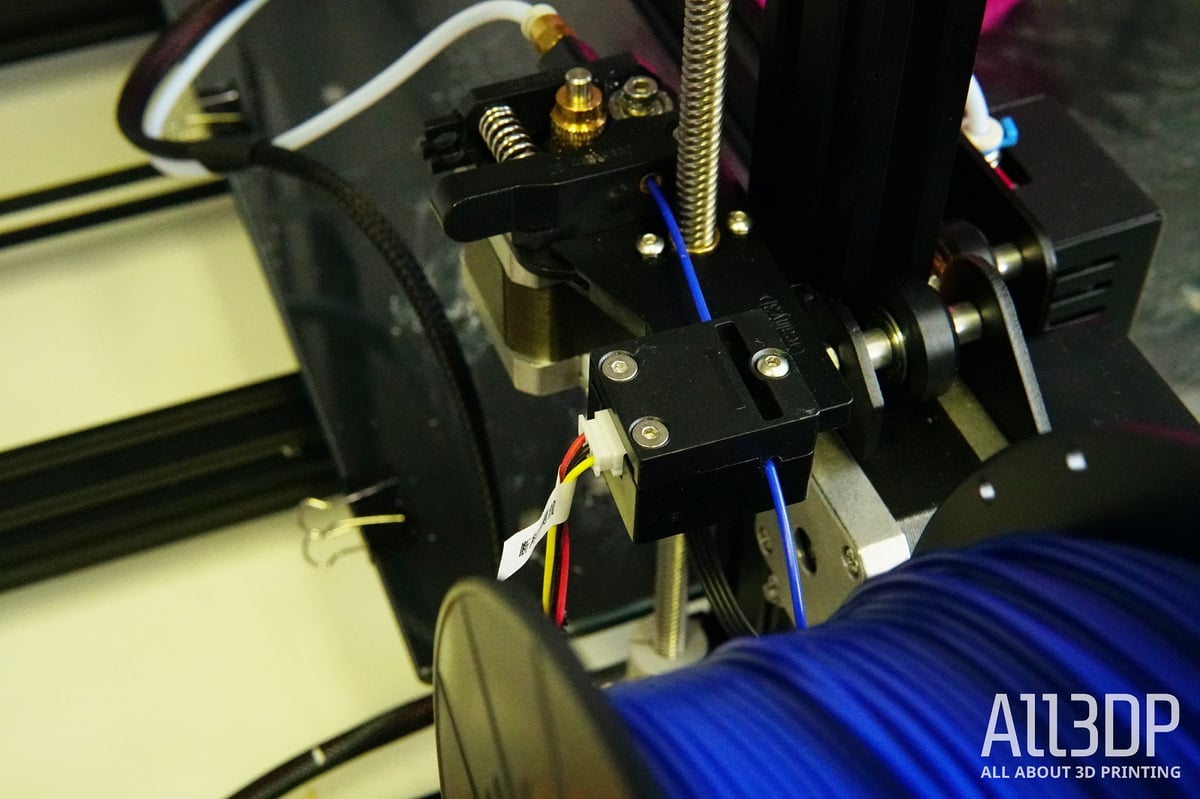

Additional useful features for utilizing the full build volume potential are the – nowadays somewhat standard – resume print function in case of a power outage, and more importantly, the filament runout detection.

If you are looking to print large projects, you are almost guaranteed to have to switch the filament spool in-between, as – even with low infill patterns – the prints will need more filament than conventional spools supply. With the sensor, you don’t risk running out halfway in-between and having to start over.

Keep in mind that this is a mechanical sensor, meaning it only trips when there is a lack of filament in the tube. Compared to the costly alternative of an optical sensor, which measures if the filament in the tube is actually moving and could, therefore, also detect possible filament failures past the sensor, it is a budget solution. But a welcome and necessary one nevertheless.

Tech Specs

General Specifications

- Technology: Fused deposition modeling (FDM)

- Year: 2019

- Assembly: Partially assembled

- Mechanical arrangement: Cartesian XY-head

- Manufacturer: Creality

3D Printer Properties

- Build volume: 500 x 500 x 500 mm

- Feeder system: Bowden

- Print head: Single nozzle

- Nozzle size: 0.4 mm

- Max. hot end temperature: 260 ℃

- Max. heated bed temperature: 60 ℃

- Print bed material: Glass

- Frame: Aluminum

- Bed leveling: Manual

- Connectivity: SD card, USB

- Print recovery: Yes

- Filament sensor: Yes

- Camera: No

Materials

- Filament diameter: 1.75 mm

- Third-party filament: Yes

- Filament materials: Consumer materials (PLA, ABS, PETG, Flexibles)

Software

- Recommended slicer: Cura, Simplify3D, Repetier-Host

- Operating system: Windows, Mac OSX, Linux

- File types: STL, OBJ, AMF

Dimensions and Weight

- Frame dimensions: 690 x 800 x 715 mm

- Weight: 14.6 kg

Where to Buy

You can purchase the Creality CR-10 S5 from the following retailers:

License: The text of "Creality CR-10 S5 Review: Hands On" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.