Maybe we just wanted to love the X1E too much and jinxed it. Our experience with other Bambu Lab printers has been outstanding, so we expected that this new machine aimed at professionals would be almost too good to be true. And it was, at least at first.

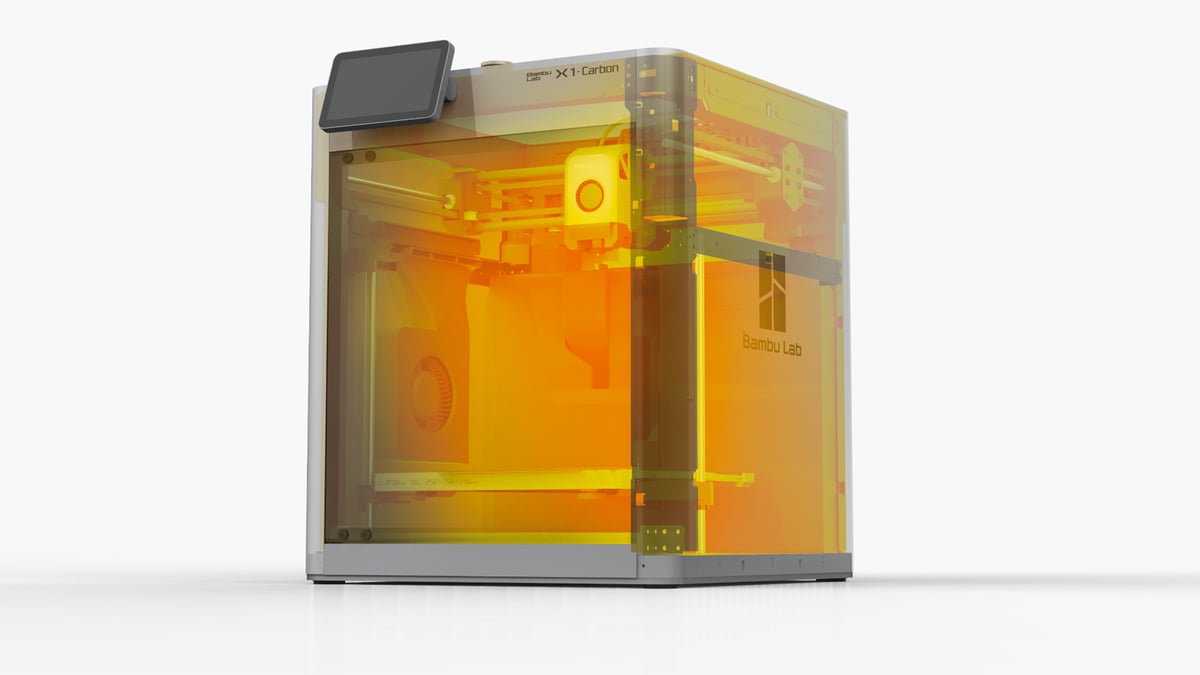

The Bambu Lab X1E, which debuted in October, is designed for users who 3D print for or as their business, such as industrial designers, architects, or small business owners, while also sporting features appealing to university print labs and company R&D departments.

To lure businesses to install a few X1Es in their offices, Bambu Lab took their already popular X1-Carbon and added features it says professional customers requested, including a heavy-duty air filtration system, a higher level of network security, an actively heated chamber to 60ºC for better results with engineering-grade materials, and a new hotter (320ºC) nozzle.

In other words, it aims to go head-to-head with the likes of UltiMaker’s S5, which at about $11,000, is almost four times the price of the X1E.

We were truly impressed with the speed, ease of use, and print quality, while simultaneously frustrated with its need for attention. As a machine for professionals, the X1E did not exhibit the level of repeatability or hands-off reliability a business would want. In fact, in our three weeks with the X1E we spent a lot of time texting with customer service, reading the support wiki, and printing modifications parts.

Pros

- Fast and efficient setup

- One-touch printing (once your library and preferences are set up)

- Automated print prep features, plus options to fine-tune

- High-uptime

- Fast print time and excellent print quality

- Multi-material printing

- Actively heated chamber and quick-heat nozzle

Cons

- Kinks in the Automated Material System yet to be ironed out

- Lacking print profiles for third-party materials

- Only a single extruder, which makes printing with support material slower

- Underdeveloped enterprise software (still single-user focused)

Unboxing & First Prints

The X1E is designed to start printing virtually out of the box, which it did. It was very easy to get up and running. Just use your smartphone to scan a few QR codes that bring up instructions, remove a few screws, plug in the filament lines, create an account online, and it’s ready to go — 45 minutes, tops.

Like the company’s other machines, the X1E is preloaded with ready-to-print part files (in 3MF format), ranging from tools to fun prints, including the iconic Benchy (pictured above). The user interface is seamlessly navigable through a 5-inch color touch screen that responds with swift efficiency. To print a part from the pre-installed library (and later, your own library) is a matter of clicking on the image and hitting print. The X1E’s sensors and software do the work of ensuring that you’ve loaded a compatible material, that the machine is in good working order, and that the bed is leveled. The X1E can read the ID chips in spools of Bambu Lab material and automatically load at that material, and if a team member tries to hit print on a part in your library when an incompatible is loaded, it won’t print, a notice appears to change the material.

In fact, any deviations from the norm prompt alerts, communicated through both desktop software and the dedicated mobile phone app. This comprehensive system all but guarantees a hassle-free printing experience, underscored by real-time monitoring (there’s also an in-chamber camera).

Despite producing a nicely detailed, perfect-surface Benchy, from there, our printing experience went downhill.

The challenge we encountered with Bambu Lab’s latest offering didn’t stem from the familiar operating system or slicer, elements we’ve navigated before. Rather, the hiccup emerged with the AMS (Automatic Material System) material changer, an external component that, while not mandatory for the printing process, proved to be a source of complexity.

The AMS, which holds four spools of filament and automatically changes between them according to your digital file’s specifications, enables you to create two-, three-, or four-material prints. Technically, you can even connect four Bambu AMS units in parallel to print with up to 16 spools of filaments. The AMS system also supports automatic filament reloading so, theoretically, you can print for days without reloading filament.

This feature is a relative novelty among professional 3D printers. Two-material printing — a base material printed with a breakaway or soluble support material — via a dual-extruder is far more common.

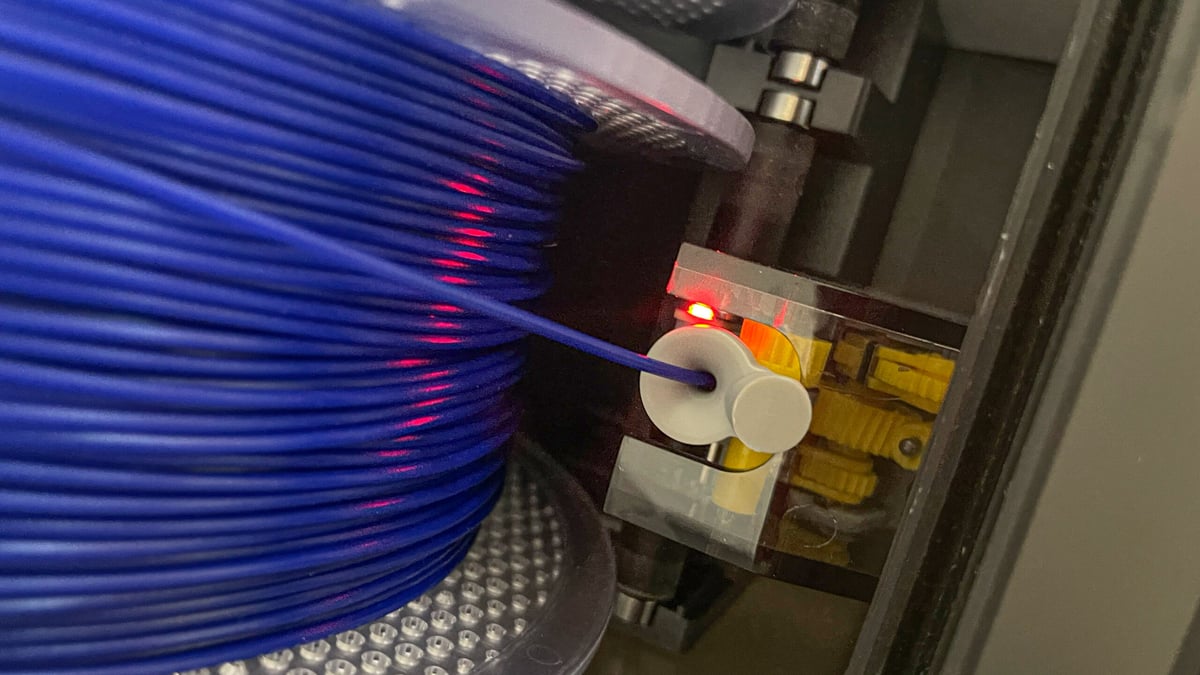

The AMS provided in the combo X1E package is no different from the AMS available for Bambu Lab’s P- and other X-series machines, and we were familiar with it.

Our initial multi-material print files were straightforward (no supports needed) workshop hooks printed in Bambu Lab ABS and Bambu Lab PAHT CF, an engineering-grade carbon-fiber-reinforced nylon for applications that require high strength and stiffness. About 10 minutes into the print job, a glitch emerged when the carbon-fiber filament refused to retract or unload from the extruder, causing an abrupt pause and triggering an alert. The filament was stuck and the error, “Failed to pull out the filament from the extruder,” persisted.

After cutting the filament above the extruder, it came loose, revealing a broken piece of filament in the nozzle. After heating the nozzle and pushing another piece of filament through, it seemed to unclog. Nozzle clogs happen, filament breaks, especially brittle carbon fiber, so it wasn’t an immediate concern.

Yet, again and again, multi-material prints, regardless of the material, failed with the same error. Every time the machine switched from one material to another, eventually, one filament wouldn’t retract from the extruder. We were using all new, just unsealed Bambu Lab brand filament. Surprisingly, this was not our experience using the AMS when we reviewed the X1-Carbon earlier this year.

In a bid to troubleshoot, we turned to the Bambu Lab wiki and tried all of the fixes detailed there: extruder disassembly, nozzle superheating, nozzle replacement, and a cold pull. But the extruder wasn’t clogged, which we could see because subsequent single-material prints in Bambu PLA Basic and Bambu PAHT CF turned out wonderfully.

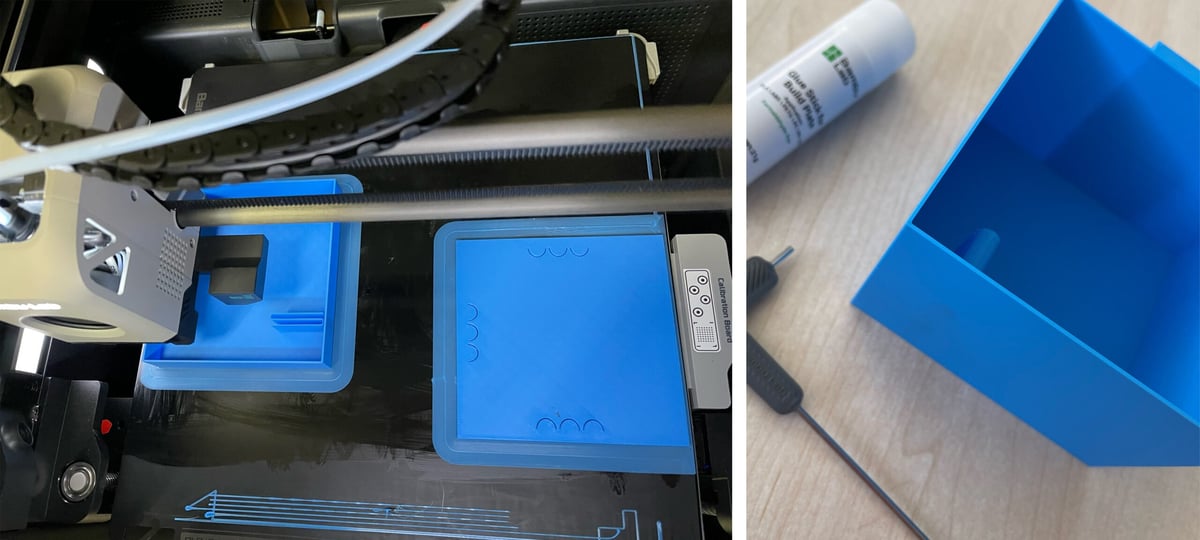

Our Bambu Lab support tech, whom we contacted via the Bambu Lab smartphone app called Bambu Handy, reviewed the video we uploaded of the problem and had some advice for the misbehaving AMS. He sent two files to 3D print a modification part to be placed between the extruder and the filament feed. The idea was to slightly adjust the filament feeder tube angle entering the extruder to be more upright. Unfortunately, those modification parts didn’t work. Undeterred, we further explored the modification route and found about a dozen Bambu Lab modification parts at various repositories online. Typically they were named “Bambu Lab Filament Pull Back Fix.” These either were positioned near the extruder or at some point along the filament route from the AMS to the nozzle.

One highly rated version of this extruder modification found at, of all places, Prusa Printables, was entitled “ShortStack: The Tiny Little Bambu AMS loading fix that might save your sanity!” from a maker named Adam L. After printing and installing it, almost like magic, no more pull-back errors. The AMS practically sprung to life.

Printing with the Bambu Lab X1E

This model in the X1 series is not much different than the X1-Carbon, in fact, it is 90% the same machine. So the speed, quality, ease of use, and excellent slicer and print management software on the X1E proved to be the same as you’ll find in our hands-on review of the X1-Carbon.

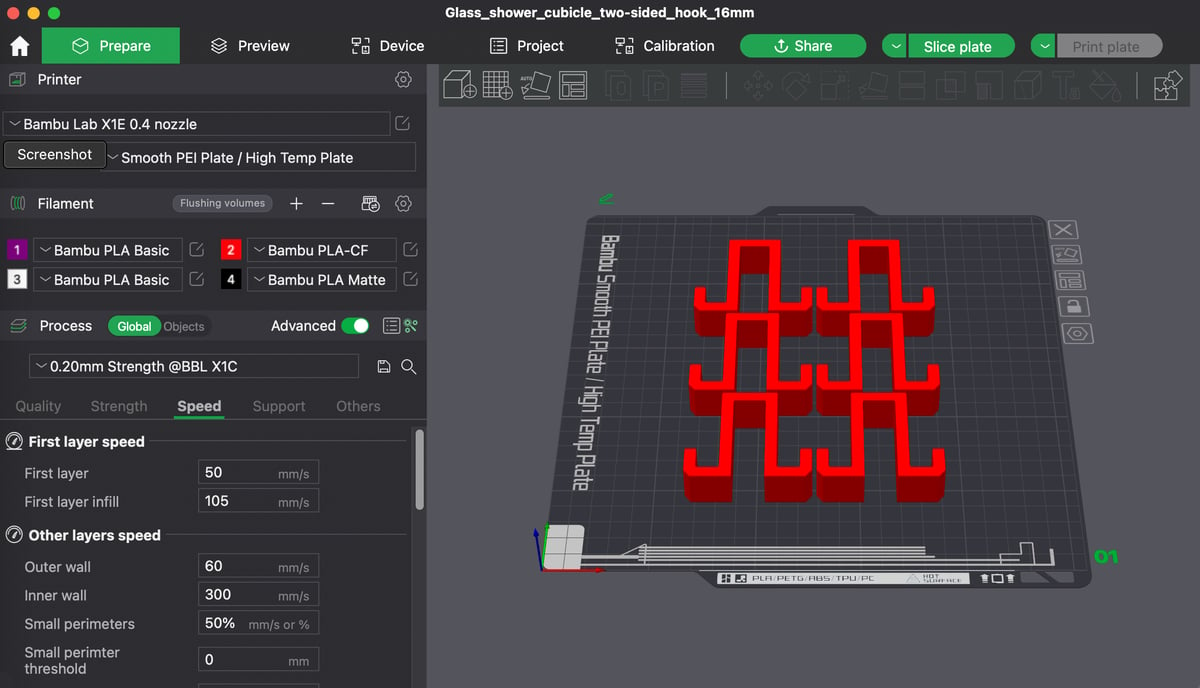

In fact, the intuitive Bambu Studio software enables you to easily slice, send, and monitor your prints from your desk. At its most basic, you simply select your printer model, material, nozzle size, and build the type of build plate you’re working with, and the software does the rest. There are handy options to auto-rotate the part, auto-separate multiple parts on the build plate, and auto-generate supports for the best results.

Printing on the Bambu Lab X1E can be an easy click-and-print experience or there are myriad options for advanced users to dial-in settings and make custom adjustments to speed, infill, temperature, detail, and much more. If you’re somewhere in between a novice and an expert user, the Bambu Lab wiki offers concise information on all of the slicer’s features.

Missing in the software, however, is the type of multi-machine and multi-user enterprise workflow management that larger businesses would want and that you can find with other prosumer 3D printers. One printer can only be bound to one account at a time, but the same account can be logged in on different computers or apps to control the printer. This workaround implies that you’d likely set up a company account and share login credentials.

Notably absent in Bambu Studio is the functionality to queue print jobs for the next available machine or exercise administrator controls over print jobs and locations. Managing a fleet of X1Es lacks the streamlined efficiency found in alternatives like the Digital Factory software on UltiMakers, Fleet Control on Formlabs, or even PrusaConnect on Prusa Research machines.

Likewise, gathering information about prints, print failures, material usage, and machine health — all data points used to calculate price per part and the ROI of 3D printing — will be time consuming.

Although third-party print farm software publishers, including 3DPrinterOS, are beginning to extend solutions for Bambu Lab printers, the X1E is not currently supported.

Actively Heated 60ºC Chamber & 320ºC Nozzle

Unique to the X1E is its actively heated chamber and the hotter nozzle temperature, so we chose to challenge it with three different carbon-fiber-reinforced materials.

The temperature management upgrades in the X1E are designed to enable the printer to deliver better results using carbon- or glass-fiber-reinforced materials (PLA, PETG, PA, PET, PC, ABS, ASA), meaning less warping, stronger layer adhesion, and better overall print quality. The hotter chamber also upgrades the built-in Material Drying feature, but Bambu Lab hasn’t yet released details.

Plus, the company says the new heated chamber enables you to print with materials not possible on any other Bambu Lab machine, including glass-fiber-reinforced PPA and PPS, yet these are not very common materials and we didn’t print with them for this review.

We found the Bambu Lab carbon-fiber PAHT parts to be outstanding. Both with small and full-build-volume parts, the surface finish, detail, and strength were impressive.

However using other brands of carbon-fiber reinforced nylon, including Luvocom 3F PA CF, resulted in less spectacular prints. Currently, Bambu Lab offers print profiles for only its own filament and a few other brands, including Polymaker and eSun. Over time, its menu of profiles should increase, but for now, any non-Bambu Lab materials will require experimentation to achieve the desired results. Using the “generic CF PA” profile with the Luvocom produced some under extrusion (shown above) and adjusting the print speed didn’t help, so more experimentation, meaning more time and wasted filament, would be necessary.

To test if the actively heated chamber would produce better results, we printed with Bambu Lab carbon-fiber PA6 with the heated chamber to 60ºC and the same prints with the chamber at 30ºC (or passively heated from the 100ºC print bed). There was no noticeable difference in the results. Of course, there are a wide range of variables contributing to whether a part would benefit from a hot chamber and we didn’t subject these prints to destructive testing, so we can’t say if the layer adhesion was affected, but the prints appeared identical.

We didn’t have material that required a 320ºC nozzle temperature, but heating the nozzle to this level took, impressively, under a minute.

Overall, we experienced mostly flawless prints (once the AMS was working) using Bambu Lab material. There were some first-layer problems that the “first-layer sensor” detected and halted the print. This technology is on other Bambu Lab printers, and is especially useful for businesses that can not continuously monitor their 3D printers.

This printhead-mounted lidar sensor is fantastic for detecting print problems before they turn into lots of wasted materials or broken parts. On several occasions the machine sent alerts about spaghetti detection and first layer flaws, yet on other occasions it failed to detect spaghetti, so while useful, it’s not flawless. Twice it halted a print for a “detected spaghetti” notice when there was no spaghetti. Once the spaghetti was actually a build-up of material extrusion that failed to evacuate fully down the shoot in the back. This had the potential to interfere with the print but fortunately didn’t this time.

Air Quality & Noise

The X1E has an activated carbon filter made from sustainable and environmentally friendly coconut shells as well as a HEPA-grade filter to capture far more fumes and particles than the X1-Carbon.

Despite the filter, you’ll still want a dedicated, ventilated room or well-ventilated area for your X1E for a few reasons. First, the HEPA filter’s fan sucks out the chamber fumes but there is still the 5 cm x 5 cm hole in the back of the unit where excess filament is extruded. This hole doesn’t seem to affect the X1E’s ability to maintain a 60ºC chamber temperature, but it does let some fumes escape.

In addition to the hole, Bambu Lab recommends that you print PLA material with the top lid removed so the chamber doesn’t get too hot – another reason to have this machine tucked away in its own well-ventilated area.

The noise isn’t too disturbing for an office, especially after the recent noise-fixing software update, but the shaking and rattling of the machine itself requires that it’s not sitting directly on your desk.

Support & Service

We can’t rave enough about our support tech who answered our support service ticket within a day or two, but when we submitted another support ticket via the Bambu Handy, the response from a different support tech was: “If your printer is an X1E we kindly ask you to contact first the reseller where you bought the printer. Resellers are the ones responsible to provide assistance and help with the Bambu Lab products purchased from them.”

This doesn’t seem like too much of an inconvenience and it’s always a good idea to build a relationship with your reseller, yet it is important to know in advance since it affects your choice of reseller. In fact, Bambu Lab isn’t selling the X1E directly to consumers, it’s only available through retailers depending on your location.

Your reseller will be your first point of contact for questions and problems, so choose wisely. All resellers offer the same price and therefore compete on service and extras. Large resellers, including Dynamism and Matterhackers, have large staff of support engineers. Check to see if your retailer has toll-free phone support and other services to make your X1E experience as painless as possible.

Bambu Lab’s support tech did say that she would help us if the reseller couldn’t, so that’s a plus.

Security & Ethernet

Data is critical to Bambu Lab to improve the printing experience, so after every print (success or failure) you can submit your data to the company. If you do not want Bambu Lab to know what you’re printing, the X1E comes with the ability to be used in isolation from Bambu Lab’s cloud-based offering.

Using just a wireless local area network (WLAN), you can send prints directly from the slicing software to the printer. The WLAN mode itself is the same as with other X1 machines. The only difference on the X1E is its Ethernet portal to provide a wired LAN option.

When we connected the printer to our network via the Ethernet cable it automatically recognized that the printer was on a local network and reflected this in the software by tacking “(LAN)” on to the end of the printer name. When we sent a job to the printer, instead of saying it was sending to the cloud, it said send via LAN. The connection speed depends on your LAN, but ours was much faster to upload prints than via the cloud. An SD card must be inserted to activate LAN only mode.

As with other Bambu Lab printers, you can also save print files to a removable SD card and physically transfer the file to the printer if necessary.

X1E supports simultaneous connections to both wired and wireless networks, with a prioritized wired network, so as soon as you plug in the Ethernet cable, it overrides Wi-Fi. The printer provides WPA2-Enterprise Wi-Fi authentication and has two separate physical switches that allow you to control the wired and wireless networks individually. If you are connected to both wired and wireless networks but want to use the wireless network, you’ll need to unplug the Ethernet cable or disable the physical switch for the wired connection on each machine, which is clearly not efficient.

An internet connection is required for firmware upgrades.

Unique to the X1E is its built-in support for various robust network authentication and security protocols. It’s compatible with EAP-PEAP, EAP-TLS, and TAP-TTLS network access authentications that enable your company to create encrypted channels and server- and client-side certificates.

Tech Specs & Price

GENERAL SPECIFICATIONS

- Technology: Fused deposition modeling (FDM)

- Year: 2023

- Assembly: Assembled

- Mechanical arrangement: CoreXY

- Manufacturer: Bambu Lab

3D PRINTER PROPERTIES

- Build volume: 256 x 256 x 256 mm

- Feeder system: Direct

- Print head: Single nozzle

- Nozzle size: 0.4 mm, o.6 mm

- Max. hot end temperature: 320 ℃

- Max. heated bed temperature: 110 ℃

- Max. heated chamber temperature: 60 ℃

- Print bed material: Steel with removable PEI plate

- Frame: Plastic, Aluminum

- Bed leveling: Automatic

- Display: 5-inch color touchscreen

- Connectivity: Wi-Fi, microSD, ethernet

- Print recovery: Yes

- Filament sensor: Yes

- Camera: Yes

- Air Filtration: activated carbon and HEPA filter

MATERIALS

- Filament diameter: 1.75 mm

- Third-party filament: Yes

- Filament materials: Consumer materials (PLA, ABS, PETG, flexibles), engineering-grade materials (PC, PA, ASA, PPA) and carbon fiber and glass fiber reinforced polymers.

SOFTWARE

- Recommended slicer: Bambu Studio, Cura

- Operating system: Windows, Mac OSX

- File types: 3MF, STL

DIMENSIONS AND WEIGHT

- Frame dimensions: 389 x 389 x 457 mm (without automatic material system)

- Weight: 16 kg

It's Not an Appliance, Yet

The Bambu Lab printers are often compared to an appliance, like a coffee maker — you plug it in, and it works. That’s a bit of hyperbole at this stage with the X1E, but there is potential for the company to get there. If your coffee maker spit grounds in your cup, you’d get a new coffee maker.

3D printing hobbyists may be willing to read support wikis, print modification parts, spend multiple prints dialing in materials settings, and accept a certain print failure rate, but this is not the printing experience businesses are looking for. This was not our experience with the UltiMaker S5, for example, which had unfailing reliability, ease of use, and a flawless Material Station.

The X1E’s Automatic Material Changer often required attention even after the modification was installed. Filament would continue to get stuck and even though the “retry” button or a wiggle of the filament tubes usually did the trick, it was time-consuming manual intervention.

As a machine, the X1E was outstanding when printing with a single Bambu Lab brand filament from PLA to carbon-fiber-infused PAHT. But as an ecosystem of software, material changer, and materials, it isn’t on the level of other prosumer 3D printers from UltiMaker, Raise3D, or Prusa Research.

Unlike others in the pro desktop market segment, Bambu Lab does not provide support or training for the X1E, or at least, the plan is to direct customers to their reseller for installation, troubleshooting, and spare parts. This may explain part of the reason the X1E retails for $1,000 more than the X1-Carbon.

Price, however, is a very big part of the X1E’s appeal. For under $3,000, businesses can find a user-friendly and satisfying introduction to 3D printing that will produce impressive parts in durable materials. We have no doubt that the X1E price tag and performance will tip the scales at companies contemplating a dive into the technology for the first time, despite the troubleshooting and adjusting, that, for now, is part of the experience.

If your company’s use case is to print single-material parts that don’t require substantial supports, it’s hard to imagine an argument against an X1E. Of course the same could be said for the X1-Carbon, so you’d choose the X1E only if you required the network security or the HEPA filter, or if you simply can’t get the results you require using filaments prone to warping without a heated chamber.

License: The text of "Bambu Lab X1E Review: Hands-On With the Pro Edition" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.