When facing a 3D printer purchase decision, finding the right choice can sometimes string out like molten filament.

The decision of which 3D printer to buy can often come down to going with the crowd or putting your trust in something lesser know or up-and-coming.

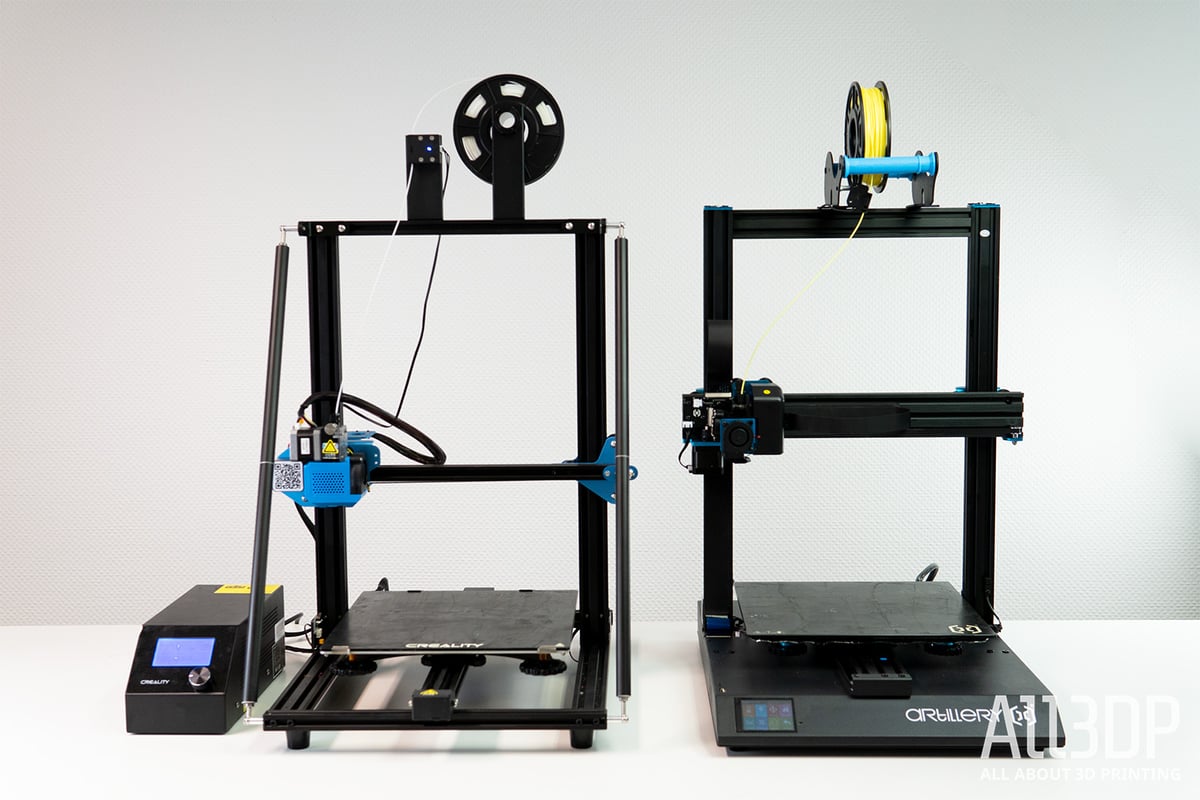

For mid-sized budget 3D printers, Creality’s CR-10 range is the go-to. With its newest iteration, the Creality CR-10 V3, the company has made further improvements to an already well-designed machine.

But it’s not such an obvious choice anymore. The Artillery Sidewinder X1 is a relative newcomer but has quickly made a name for itself with a slick look and desirable features.

Both machines pack similar features – large build volumes, direct drive extruders, and fast-heating hot ends and beds – so which to select? We’ve reviewed both, but we haven’t put them head to head… until now. Here are 17 questions that could be asked of the CR-10 V3 and Sidewinder X1 and how the printers stack up.

If you want to know more or think of any questions you want to have included in future shootouts, let us know in the comments below.

At a Glance

The Specs

The Shootout

Looking at raw numbers doesn’t tell the full story and can be a bit dull, to say the least. Below we have asked ourselves several real-life questions concentrating on all the nitty-gritty details that could influence a buying decision.

Equipped with a stop-watch, thermometer, decibel meter, filament, and a whole lot of time, we went to work.

We have divided our questioning into three categories.

Setup and Launch

Which printer quickest to assemble?

The first thing you have to do when setting up your 3D printer is to assemble it. Nowadays, complete DIY assembly kits are scarce, and 3D printers typically arrive in a semi-assembled state, keeping build times down and nerves considerably unfrayed.

Both printers ship semi-assembled, meaning both can be put together in as little as 15-20 minutes. However, due to its more compact design with a base unit that integrates with the frame, the Artillery Sidewinder X1 takes it over the CR-10 V3. In short, you need about four fewer screws (from the cross-bearing) than the CR-10 V3 and have a tidier time with the ribbon cables.

Which printer boots quickest?

We’ll admit, it’s not the most decisive of purchasing factors when comparing two printers – nevertheless, time to put that stopwatch to work. The Sidewinder comes strong out of the gate with a boot time of 7 seconds, closely followed by the CR-10 V3, which takes 10 seconds to awake.

How do you level the beds?

Both print beds need to be leveled manually by loosening and tightening the leveling knobs on the beds’ underside, albeit with slightly different methods.

The CR-10 V3 does so by disabling the motors, letting the user freely move the printhead across the build plate to various zones for leveling. The Sidewinder X1 uses an assisted bed leveling method, with the print head moving to one of five preset points on the build plate upon a button press.

Which bed leveling is quicker?

Since both beds require manual leveling, there’s no clear advantage to either. It comes down to how flat your print bed is in the first place and, ultimately, how quickly you can wrastle the print head and knobs.

Which hot end heats quickest?

We set the finishing line to 205°C and ready, set, go, the Creality CR-10 V3 lumbers to temperature in 1:20 min, with the Sidewinder X1 downright sprinting the distance in 43 seconds flat.

Which bed heats fastest?

Firing up the CR-10 V3, it took 2:30 min to reach out target temperature of 60°C – on the display, that is. Our digital thermometer registers 55°C, taking over another minute hone in, taking 3:55min in total.

The Sidewinder, on the other hand, took about 40 seconds to get to the 60°C mark – again, on display. Turns out the portrayed 60°C is actually 40°C on the plate surface. At around 2 minutes, the build plate reached 50°C and pretty much stayed there (we waited 20 minutes.) To get close to the target of 60°C, we had to set the Sidewinder to 70°C. Again, the printer displayed 70°C in under one minute but took 3:30 minutes to hit our initial target of 60°C.

Testing higher temperatures (80°C+), the Sidewinder managed to hit 80°C in 4:30 min. The CR-10 V3 took 6:15 min to do the same.

Although the Sidewinder X1 shows greater inconsistency in displaying the bed’s actual temperature – no big surprise that it outperforms the V3, considering it’s known for its fast-heating AC-powered print bed – the CR-10 V3 gave the most reliable readout, even though it’s unquestionably slower.

Which is the quickest to start printing?

Now, with the data gathered above, we already have some indication of which printer might win this one. Timed from inserting the SD card to the first layer of PLA going down, to no surprise, the Sidewinder takes it decisively over the CR-10 V3 with 2 minutes flat compared to 4:30 min.

Hardware

Which is quieter?

Whether a printer is whisper-silent or loud as a jet engine shouldn’t really influence the print quality. But, as many users will have their machines in a residential setting, a printer capable of stealthy operation might be preferred.

The Sidewinder X1 idles at ~35 dB and operates at ~45 dB (measured at a 1 m distance.) This increases to ~53dB when listening directly to the nozzle.

In comparison, the Creality CR-10 V3 idles away at 45 dB and operates at ~52dB (again, 1m distance.) Directly at the nozzle, the V3 emits 65dB.

In case you are wondering if 45dB and 53dB make much of a difference – it does. The Sidewinder X1 is notably quieter.

Which printer has the better motherboard?

Both printers sport different mainboards, but with similar features. In Creality’s case, it is a Creality-manufactured V2.5.2 motherboard. The Sidewinder X1 uses a Makerbase MKS GEN L 1.0 motherboard. Both have the crowd-pleasing TMC2208 silent stepper motor drivers installed – a key element to reduce the printer’s motor noises and smoothing out movement.

Both motherboards accept upgrades, such as a dual extruder setup or – in the V3’s case – the possibility to upgrade to a touchscreen. As none outperforms the other drastically, we rate it as a tie.

Which printer has the best UI?

Proper UI can make quite a difference in one’s printing experience.

In this case, it is quite an unfair battle. On the one side, we have the CR-10 V3 that features Creality’s tried and true external control unit sporting a 3.5-inch LCD screen with a rotary knob. In the other corner, we have the X1 with a same-sized color touchscreen.

Both UI’s allow for core print adjustments, so it comes down to personal preference. In our case, we prefer the X1. For one thing, the V3’s UI is a bit convoluted at times – some functions are stored away unnecessarily in sub-menus, and because touchscreens dominate our lives in pretty much every sense. Going back to a rotary encoder is starting to feel a bit old hat.

Both UI’s are functioning trouble-free, though.

Which firmware is easier to upgrade?

Both the Creality CR-10 V3 and Sidewinder Artillery X1 allow you to change the stock firmware that comes flashed to boards.

Of the two, the CR-10 V3 is the easiest to flash with new firmware: prepare your control software with the firmware to flash, connect your computer to the printer via USB, and you are basically good to go. The Sidewinder, on the other hand, requires a few more intermediate steps, requiring the user to open the casing along the way.

Which printer is safer?

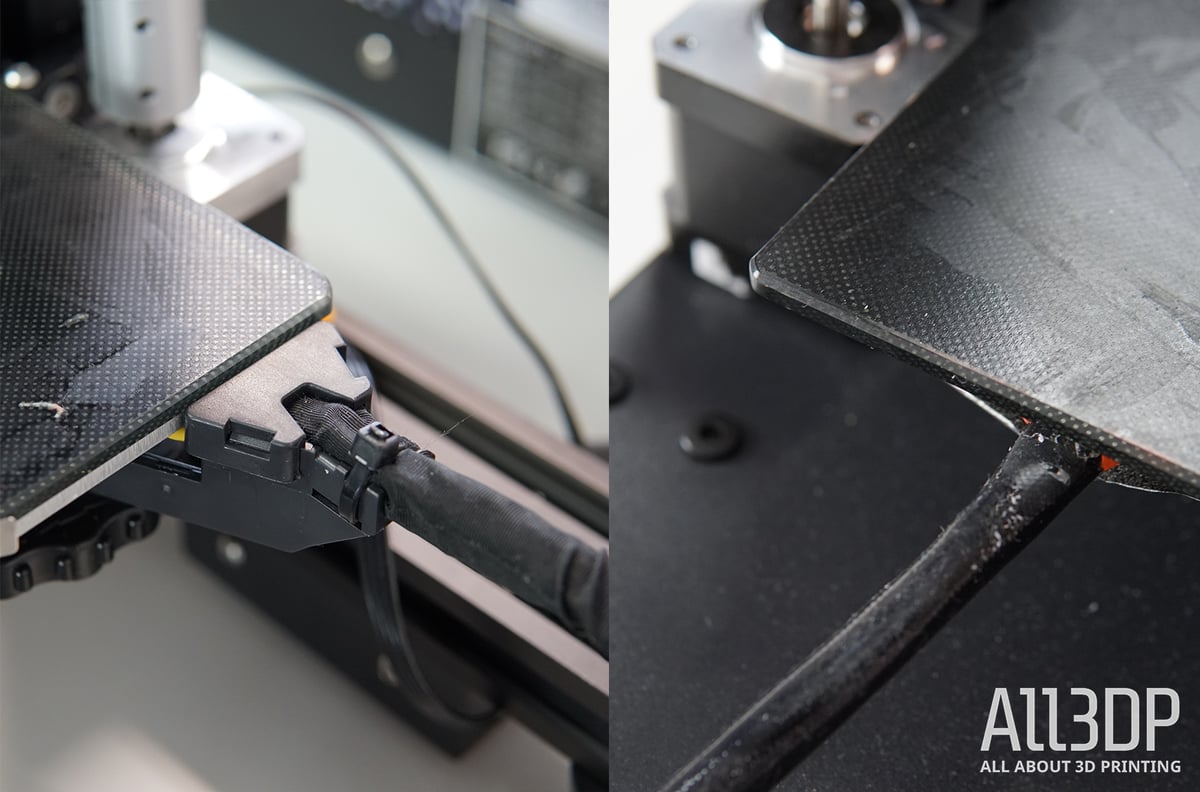

Both printers have grounded power supplies and thermal runaway protection enabled. And this category would have probably been a dead heat were it not for the Sidewinder’s lack of strain relief on its main-carrying heated bed power cables.

While having a fast heating bed is a beautiful thing to have, it shouldn’t be at the expense of improper support on moving parts such as the bed cables, not least because damaged and exposed cables could carry the serious risk of injury.

The CR-10 V3 ‘s bed is only 24V powered and features proper strain relief. It might be slower, but it’s also ostensibly safer. Owners of the X1 should outfit the printer with a 3D printable strain relief.

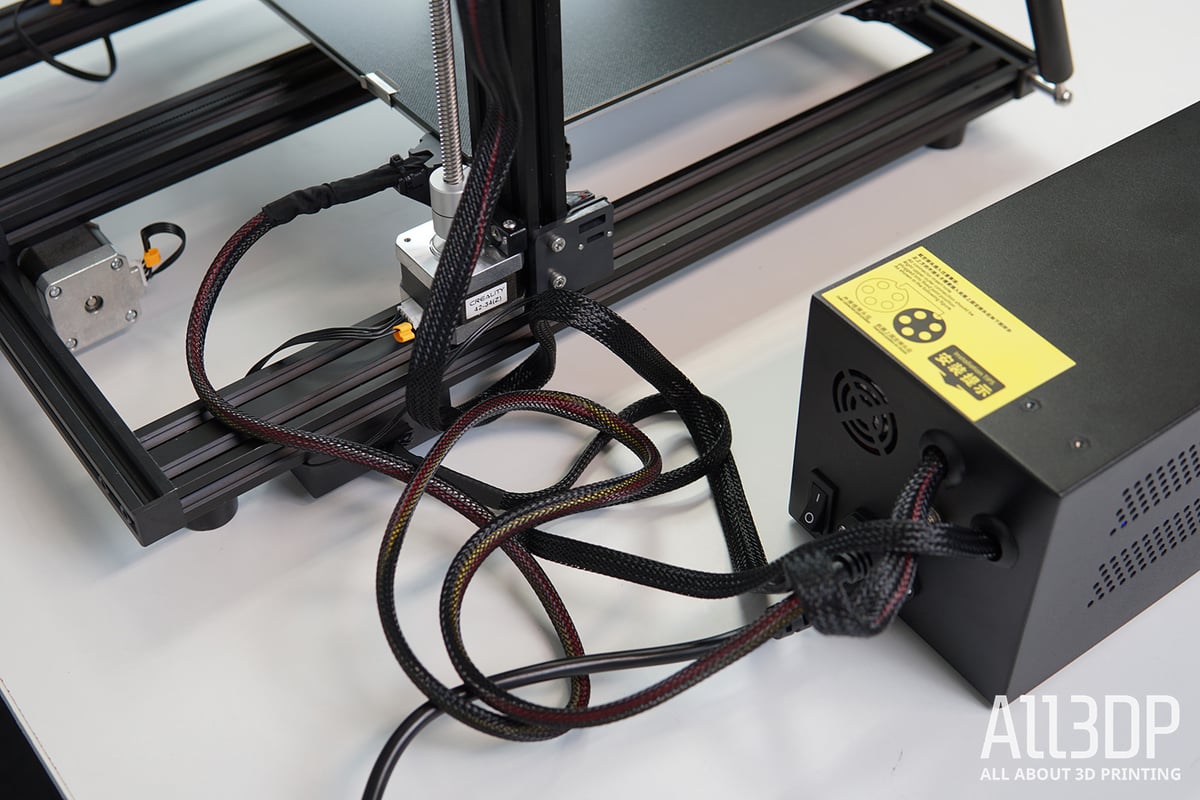

Which printer is tidier?

Well, this is a bit of a no brainer. The CR-10 V3 has the umbilical control box and the chunky spaghetti of cabling that comes with it.

You got to hand it to Artillery, with the control unit integrated into the bottom case and its usage of well-routed ribbon cables.

Printing

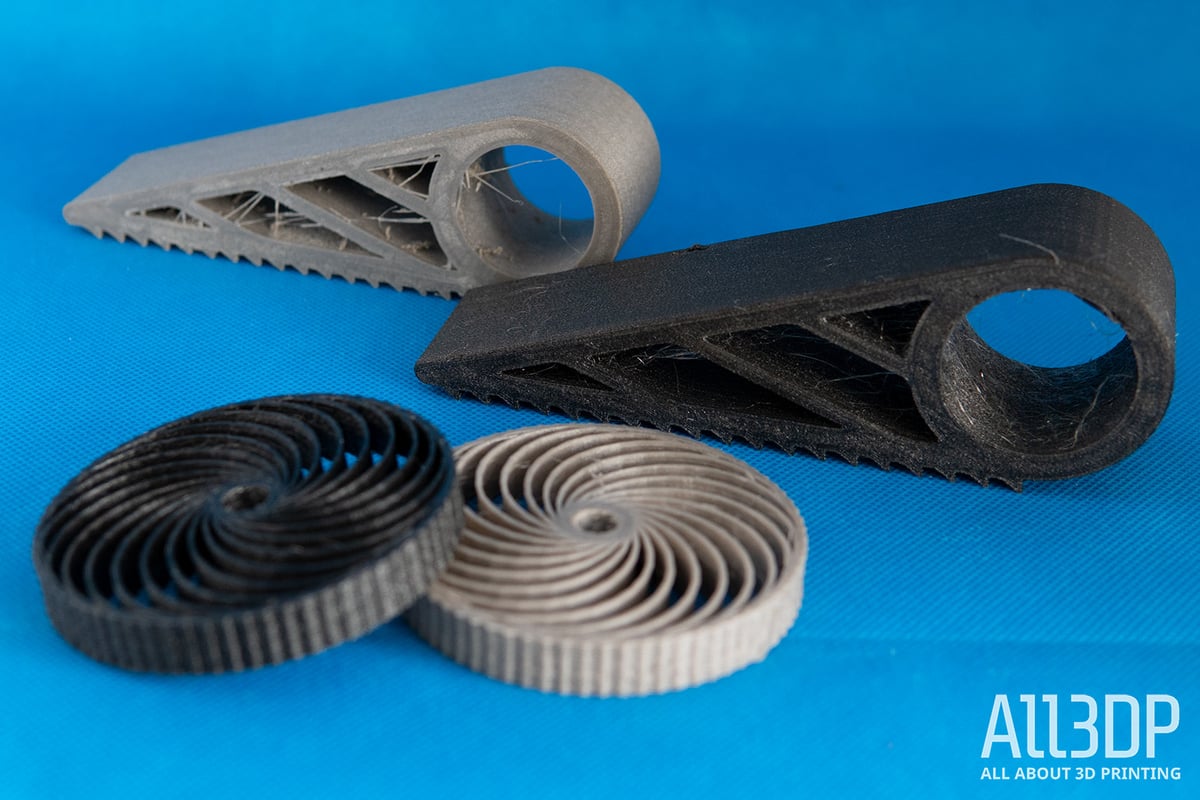

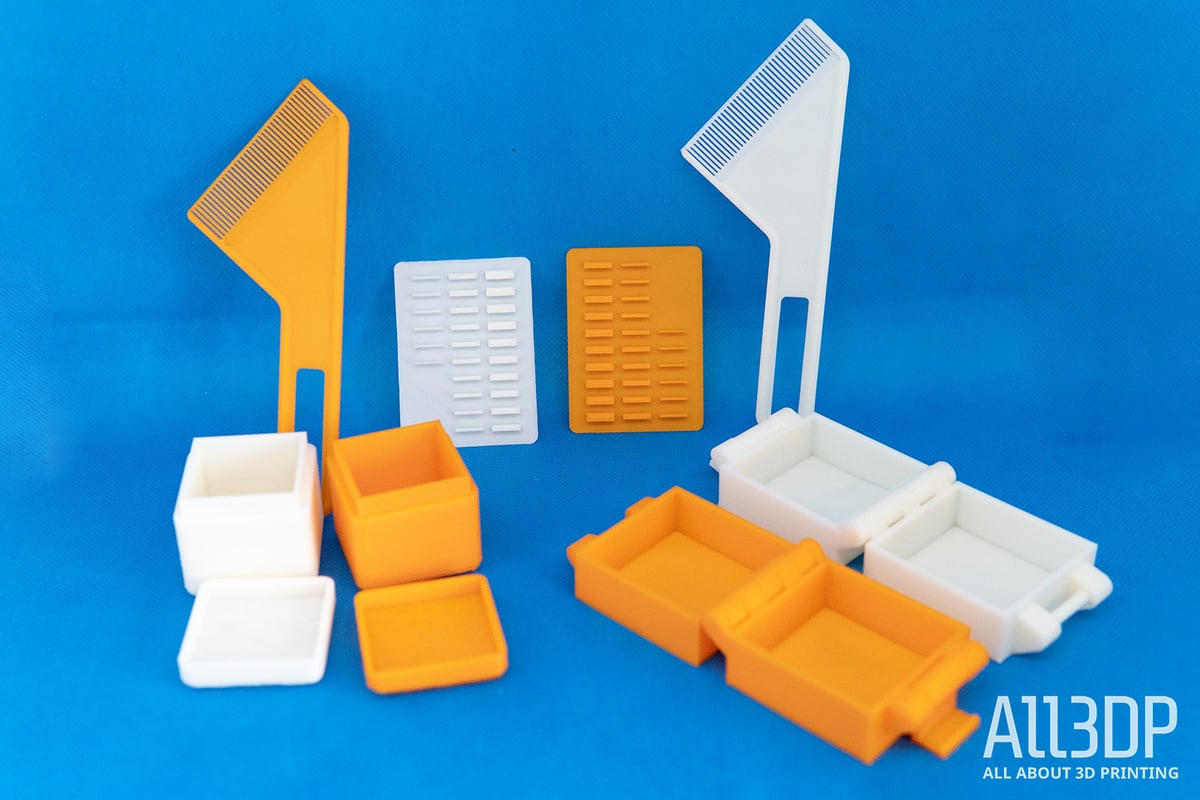

Which printer prints flexibles best?

Flexible filaments can be a hell of a mess. Luckily both printers feature direct drive extruders, which makes filament feeding that much easier, and in the context of this shootout, keeps things even-steven. With printing speed at 30 mm/s, results are very similar except for a bit more prominent stringing on the X1 – something we encountered multiple times during our review, too – the X1 seems to struggle ever so slightly with oozing, despite appropriate retraction settings.

Which printer prints ABS best?

We know ABS can be a party pooper. While the material offers many favorable properties, printing it on open-frame printers such as these can be frustrating. More forgiving filaments with similar properties, such as PETG, are widely used alternatives.

Nonetheless, we ran a couple of ABS prints on both the CR-10 V3 and Sidewinder X1 and were pleasantly surprised. Both printers gripped prints well and exhibited little to no warping. Choose your models carefully –we use models more suited to such printing of ABS – and keep in mind that the Sidewinder X1’s print plate falls short 10°C, so adjust it accordingly.

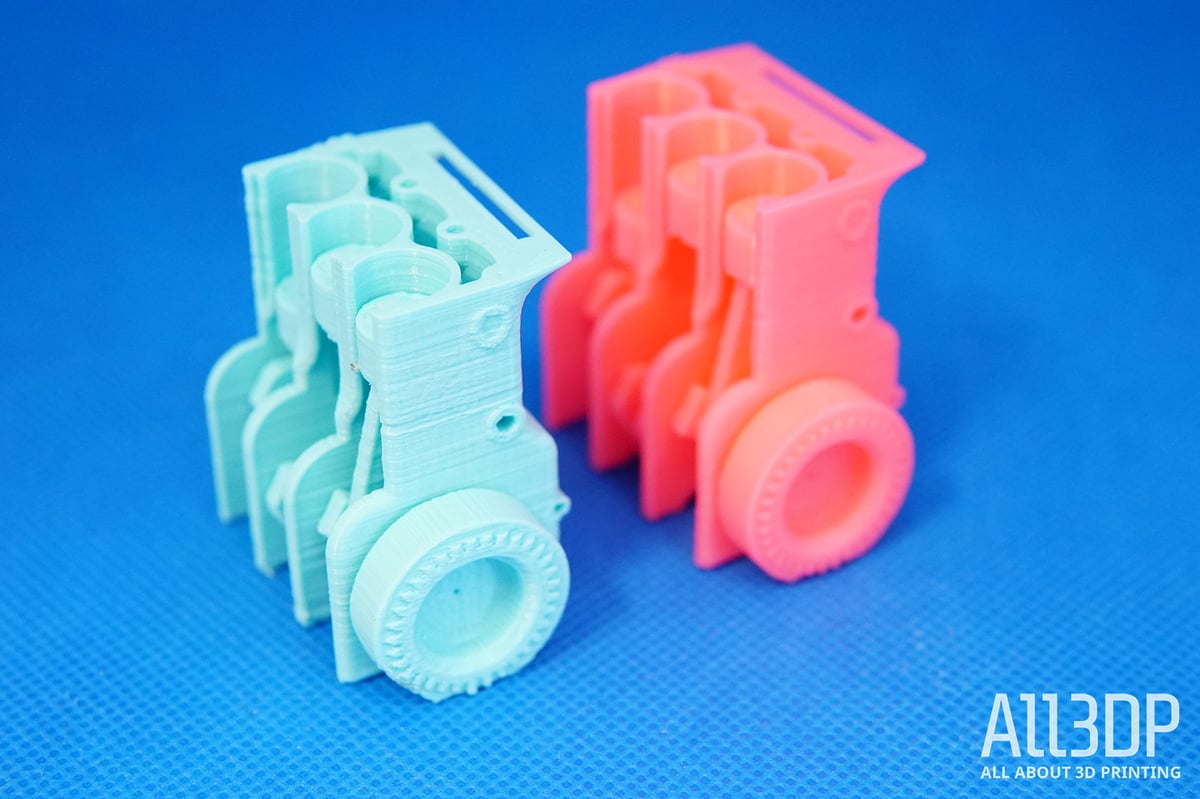

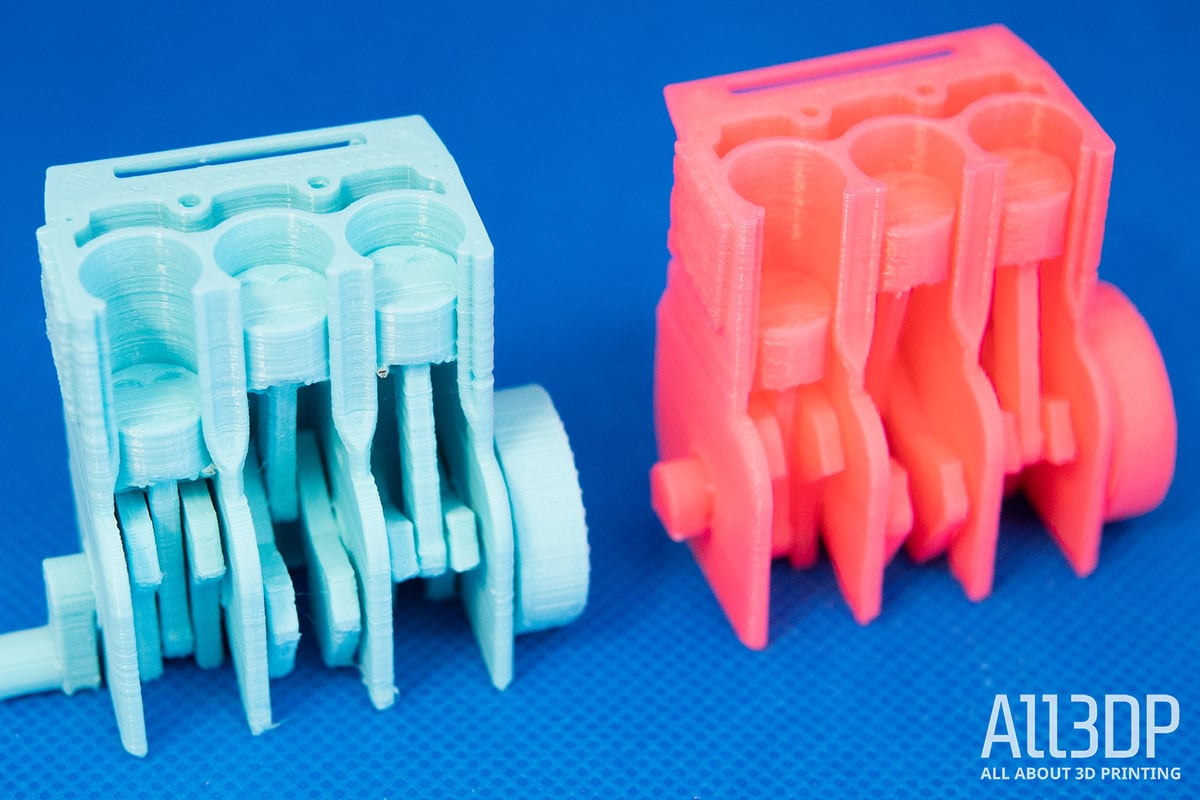

Which printer has finer detail?

After running many prints with different materials, we found the CR-10 V3 produces finer prints. The Sidewinder X1 struggled with overhangs, visible layer inconsistencies, and intricate detail from time to time (particularly when printing speeds at 50-60 mm/s.)

As we found out in our full-on review of the Sidewinder (and appears to be common knowledge in Sidewinder X1 forums,) the part cooling fan placement on the X1 isn’t the best and could be responsible for some of its issues. The dual part cooling fan on the CR-10 V3 seems to influence its ability to print fine details successfully.

Which prints support better?

To conduct this test, we ran multiple prints with identical settings on both machines. As mentioned above, the dual part cooling system on the V3 comes out on top, resulting in easy to break off support. On the Sidewinder, some supports fused to the print, resulting in unwanted fractures and breakoff points.

Conclusion

We hope we could clear up some (hopefully all) of your questions regarding the nitty-gritty differences or similarities between these two large-sized budget 3D printer top dogs.

In summary, the Sidewinder X1 scores big with its setup and hardware, whereas the Creality CR-10 V3 tops out with stock print quality. There’s nothing particularly damning in either case because both can easily be modified to improve their performance with relatively little effort.

Both printers used in this comparison were in their vanilla state, using identical slicer settings.

While we do favor one printer over the other for some of the questions, our aim here isn’t to hoist one up on a pedestal over the other. Just answer cold hard questions, and let you see how they compare across less common criteria.

Check out our reviews for both the Creality CR-10 V3 and Artillery Sidewinder X1 for an in-depth look at what they’re like to use.

License: The text of "Artillery Sidewinder X1 vs Creality CR-10 V3: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.