Are you considering to replace your 3D printer print bed by an Anycubic Ultrabase? Here’s all the information you need plus our experiences on Anycubic’s unique glass bed to answer your question: Is worth its money?

What is the Anycubic Ultrabase?

Basically, the Anycubic Ultrabase a very sophisticated glass bed that provides better adhesion to prints, but at the same time, releases them very easily.

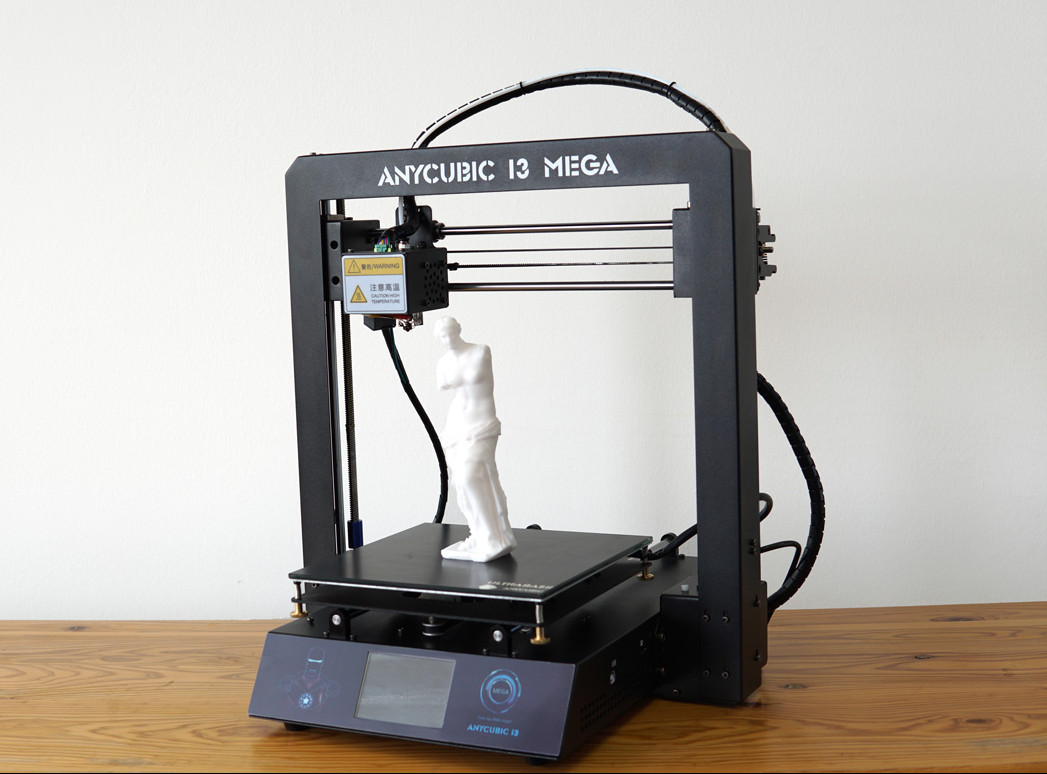

It was originally released as part of the Anycubic i3 Mega. However, now it is also available as a separate component, meaning you can install it on many third-party 3D printers.

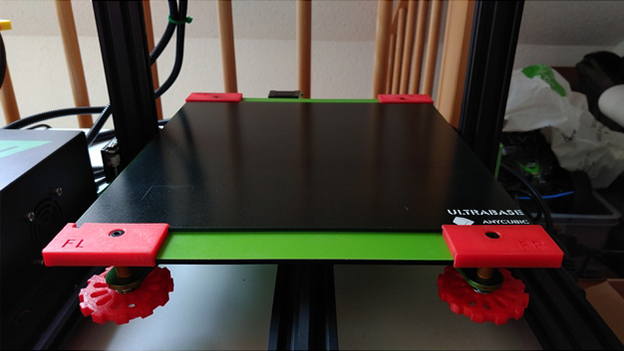

Some enthusiastic reviewers described the Ultrabase’s surface as “magic”. It’s true, 3D printed parts stick extremely well to the surface. After the print is finished and bed cools off, you can remove your prints with your bare hands. And only a little effort is needed to lift 3D printed objects off the surface.

The Anycubic Ultrabase provides a smooth first layer finish. Depending on the filament you use, it can almost look like glass. However, you will always be able to see the nobs on the Ultrabase’s surface.

According to Anycubic, the Ultrabase works with a number of materials, but suspect that it may be compatible with more. PLA, TPU, ABS, PC, Nylon, PP, and PETG.

Pros & Cons

Pros

- Good quality

- Much better adhesion than most print surfaces

- After cooling, the prints can be removed with ease

- Fast customer service

- Supports all filament types

Cons

- No instructions

- Installing can be tricky

- Doesn’t support Autoleveling

The Verdict

For us, the Anycubic Ultrabase worked nicely – we tested it pre-installed on an Anycubic i3 Mega.

The appeal of this high-tech glass bed is very clear. By releasing prints as it simply cools off, the Ultrabase does away with the scraper, hairspray and glue sticks.

Anycubic designed its glass bed to be low-maintenance. It’s a good idea to clean it with alcohol every few prints to remove small particles of filament, but otherwise, you’re off the hook.

Other methods like hairspray or glue sticks on glass made a big mess. You need to remove residual glue from the prints bottom, and also take care that you clean the glass regularly.

The downside of the micro-structure mechanism is that you need wait until it has cooled all the way down before you try to remove your prints.

Because we know that not everyone has the time to wait, or simply isn’t patient enough, we tried to remove prints while the Ultrabase was still warm. In our experiments, we found that it is not possible to remove a print while it is still at 40C°. On the one hand, we were really impressed by the excellent adhesion.

Nonetheless, we gather that is could be possible to take prints off the glass bed using a scraper. However, some reviewers who attempted just that reported that they damaged the glass bed’s surface. That’s why we mustered a little bit more patience until it had cooled down to 35°C. Now, the print came off with almost no force at all.

The package comes with a paper that is labeled as “you can use this for leveling” – some reviewers have complained that when they level their Anycubic Ultrabase using this paper, the nozzle ends up too far off the surface. So, you will want to use a thinner sheet of paper, like receipts.

How Does the Ultrabase Work?

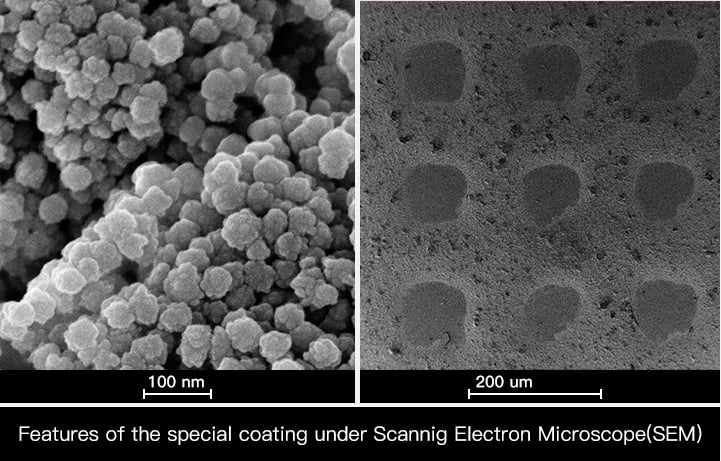

The surface is covered with a micro-structure of porous coating that provides a high degree of adhesion between the part and the print bed. Imagine the tires of an ATV that ensure the car has sufficient grip on the ground. That’s how the glass bed clings to your prints!

Anycubic’s glass bed harnesses the power of thermal expansion to help release parts from the print bed. As the print bed is heated up these pores expand. Then, as the print bed cools down, the pores contract again, forcing the deposited plastic out, because it does not contract. As a result, you can normally remove print from the bed with your bare hands, or only little nudge from a scrapper.

Why is the Ultrabase Sold Separately?

Initially, the Anycubic i3 Mega did not ship with theAnycubic Ultrabase, because it was released after the 3D printer. When you order a Anycubic i3 Mega today, the kit contains the glass bed. So, these early customers have now the chance to upgrade their machine to the new standard.

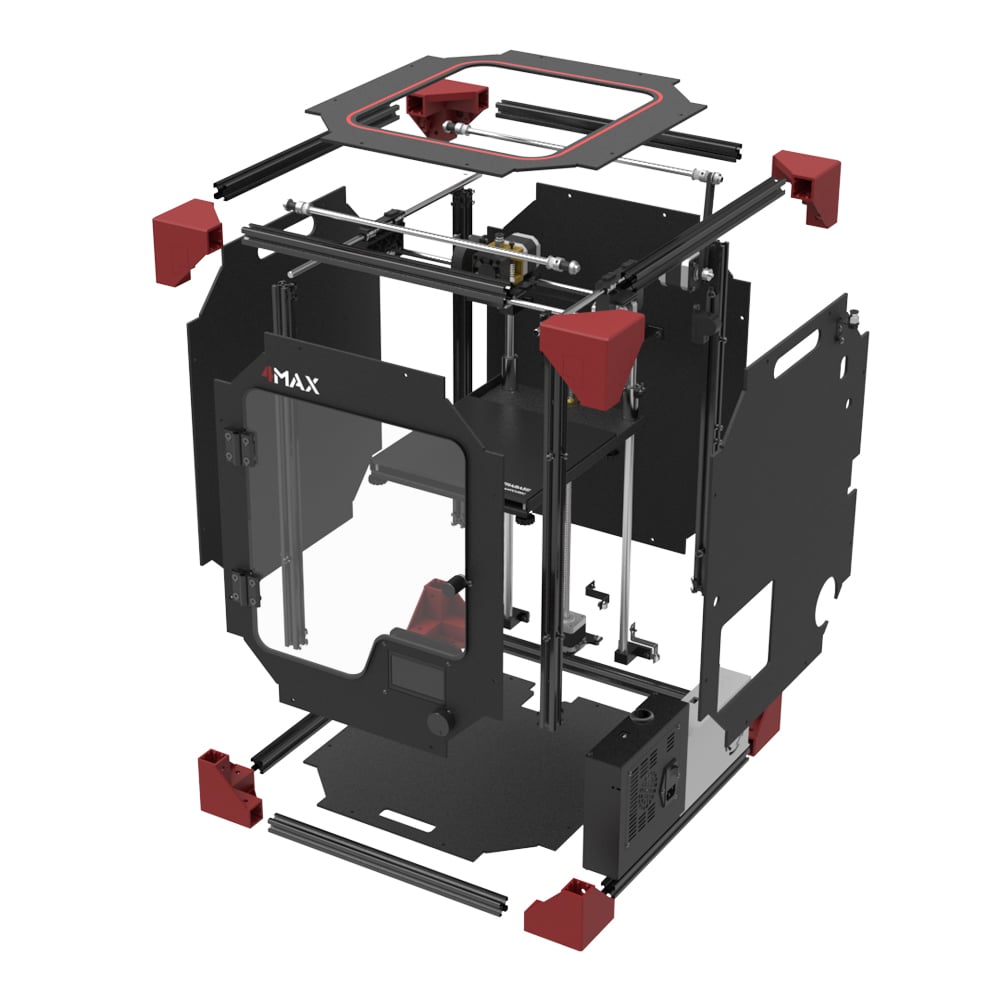

Today, the Ultrabase is included with almost all of Anycubic’s FDM 3D printers:

- Anycubic 4Max (Formax)

- Anycubic i3 Mega

- Anycubic Modular i3

The exception is the DIY Kossel, Anycubic’s Delta 3D printer. However, Anycubic sells two circular glass bed models separately. So, it is possible to upgrade this 3D printer with the glass bed.

What Versions of the Ultrabase are Available?

The Ultrabase is available in a broad range of sizes and configurations that cater not only to customers of Anycubic. In addition, it is suitable for a great many other 3D printers.

There are two rectangular models of the glass bed that only include the coated glass. Buy these types to upgrade your 3D printer if you have already installed a heated bed.

- 214 ✕ 214 mm

- 310 ✕ 310 mm

In addition, Anycubic has released one version that includes the coated glass bed and a heated bed. Hence, this type is the ideal choice if you want to upgrade your 3D printer and a heated bed at once.

- 220 ✕ 220 mm

Last but not least. Anycubic also caters to Delta frame 3D printers. You can take your pick from two diameters. Please note, that will need a heated bed already installed.

- 200 mm Diameter

- 240 mm Diameter

There’s also a new “Ultrabase Pro”which was first installed in the Anycubic Chiron. At the time of writing in July 2018, it’s still too early to tell what makes the Ultrabase Pro special – but we’ll keep you updated.

How to Install the Ultrabase

Unfortunately, the Anycubic Ultrabase doesn’t come with proper instructions. Here’s how you install it:

- First, unplug the 3D printer and peel off any stickers or tape that may be on your build plate.

- Next, clean the surface of the print bed using a cloth soaked in alcohol. This will allow the glass bed to stick properly to the print bed.

- Now, peel off the tape at the back of the Ultrabase and place it on top of the print bed. Make sure that the edges of the Ultrabase align with edges of the print bed beneath.

In case you want to change the printing surface, simply fasten it to the print bed with a binder clip.

Using the Ultrabase on Other 3D Printers

The Ultrabase is available in a broad range of sizes and configurations that cater not only to customers of Anycubic. In addition, it is suitable for a great many other 3D printers.

Thanks to the many types of the glass bed it possible to install in on many 3D printers not manufactured by Anycubic. To date, we have heard from many users who use it successfully on the Creality CR-10, Tevo Tornado, and other 3D printers.

Ultrabase Alternatives

Are you still not sure, if the Ultrabase is for you? Read about the time proven alternatives and how they compare.

Blue Painter’s Tape

To some people blue tape is magical. We think that it is a very good surface for print beds. For one it is dead cheap. The second reason is that you don’t need hairspray or glue to make your prints stick. So in this regard, it is similar to Anycubic’s glass bed.

However, you still need to replace the tape every 10 to 20 prints. Depending on what quality your tape, it can be an unpleasant experience to scrape the residues off. Also, blue tape does not release prints quite as smoothly as the Ultrabase. Keep a spatula or spudger ready to loosen your parts.

To install blue tape on your print bed, remove any old surface treatments from the bed. Then lay strips of tape diagonally on the bed. Be careful that the strips do not overlap, because they will not stick together properly.

Hairspray or Glue Stick on Glass Bed

This one is nowasdays already a classic! Basically, it is simple as applying hairspray or glue stick onto a glass bed. This alternative to Anycubic’s glass bed is a time-proven technique that is practised by thousands of makers worldwide.

On the one hand, your prints get the shiny and smooth surface that only a glass bed can provide. On the other hand, your prints profit from the adhesion supplied by sticky agents like hairspray or glue sticks.

The downside of this method is that you will need to clean the bottom surface of your print, as residue of hairspray or glue will stick to it. The same goes for the glass bed as well, over the course of several prints several layers of hairspray or glue will accumulate. To keep your gear nice and tidy, remove the residues in regular intervalls.

3D Print Bed Adhesion Stickers

These stickers be installed fairly easily. Simply removed the film from the sheet to expose the double-sided adhesive. To ensure that no air bubbles get caught between the bed and the adhesion sticker, unroll it slowly and gently swipe it with a ruler.

Similar to the Ultrabase, the stickers surface provides excellent adhesen of prints to the bed. Once, the bed has cooled down the sticker releases prints with only minimal force neccessary.

Like Anycubic’s glass bed, adhesion stickers take out the pain of maintaining the print bed. This is because you don’t have to clean off hairspray or glue from your glass bed. In short, less mess makes for a better 3D printing experience!

License: The text of "Anycubic Ultrabase Review – Is It Worth It?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.