Two of the biggest names in desktop 3D printing, UltiMaker and Formlabs, launched new machines in April that marked a departure from their previous models, but not surprise developments. Both companies have had their eye on the broadening market for light industrial 3D printing applications and manufacturers. Their machines are positioned as ideal for the shop floor.

This article, updated monthly, is where we cover all the best new prosumer, professional, and industrial 3D printers hitting the market.

Earlier in 2024, Chinese manufacturers were the first out of the gate with a large-format industrial FDM from CreatBot, and an upgraded metal laser powder fusion from 3Plus3D that piles on the features. Farsoon was soon to follow with its own new multi-laser metal laser powder bed fusion machine with automation features for mass production. There was also the new laser-wire DED from Meltio, which fulfilled its mission to make the technology more accessible. Plus, Prusa debuted on our professional list with its high-temperature delta FDM.

Looking back at 2023, it could easily be described as a year of fewer-than-usual 3D printer launches, but it was perhaps a year of quality over quantity. You can see everything that launched last year in this linked below.

No matter which technology you’re interested in and in which industry you operate, there’s sure to be a interesting new printer for you in 2024!

UltiMaker's Factor 4 FDM

(Apr. 22, 2024) UltiMaker’s new FDM aims to fill a gap in 3D printing between consumer and industrial machines, marrying ease-of-use with engineering-grade materials.

Rather than beef up its S7, which is just one year old, UltiMaker created something new that still looks very UltiMaker. Factor 4 has a sturdy steel and aluminum chassis, an actively heat-controlled chamber up to 70ºC, triple-insulated build volume, a direct-drive extruder with a bigger motor, and a nozzle temperature that can reach 340ºC to enable materials, such as PPS-CF, PEKK, and Ultrafuse metal filaments.

Factor 4 has a 50% increase in productivity compared to the S series, the company says. The UltiMakers’ dual extruder effectively prints two materials at the same time without the filament retraction of the material changers found on Bambu Lab and now also on Creality and Anycubic.

Also contributing to the predictability of the Factor 4 is new software designed to track and trace the full printing process. There’s a new suite of sensors that monitor real-time print data and material performance delivering reports after every print job to provide a level of part validation and quality control.

Tech Specs & Price

- Technology: FDM

- Build Volume: 330 x 240 x 300

- Dimensional Accuracy: within ± 0.2 mm or ± 0.2%

- Air Filtration: HEPA filter

- Materials: Available at launch: UltiMaker PPS CF and other UltiMaker-branded materials, such as PLA, Tough PLA, nylon, PETG, PET CF, and PVA, plus validated materials from BASF Forward AM, Kimya, Polymaker, LEHVOSS, Jabil, and others. Factor 4 will be compatible with materials on the UltiMaker Marketplace, with 250 pre-tuned print profiles.

- Filament Size: 2.85 mm

- Price: around $20,000

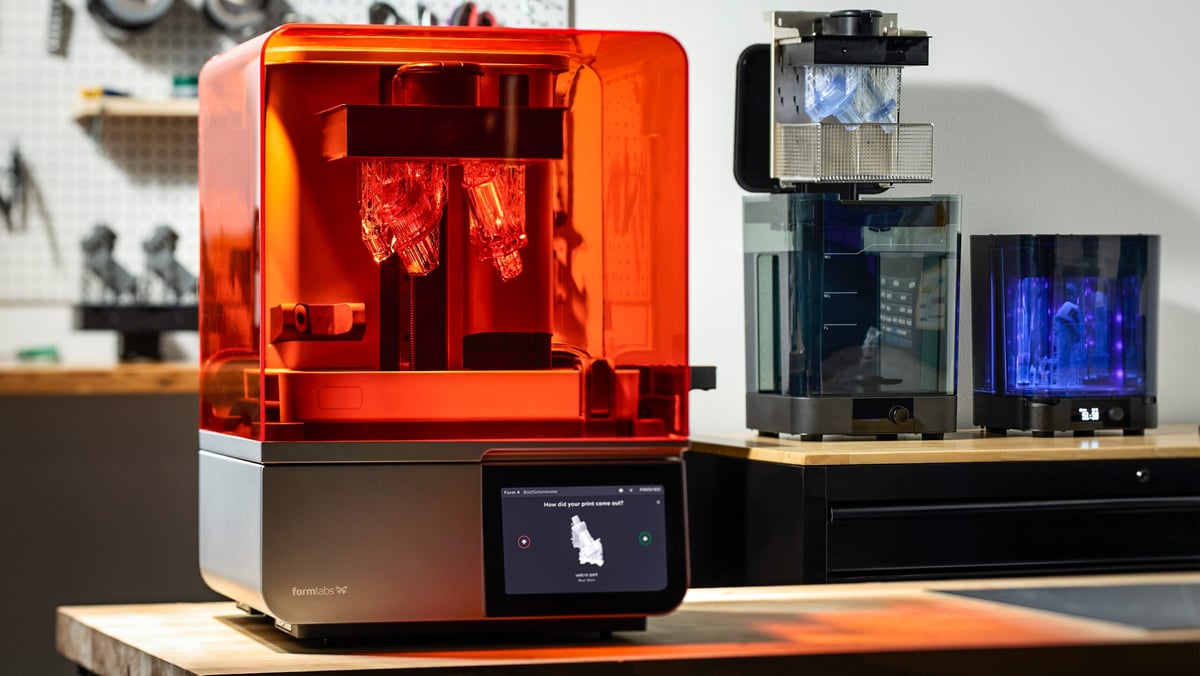

Formlabs' Form 4 LCD

(Apr. 18, 2024) At under $5K, the new Form 4 from Formlabs may set a new benchmark in resin 3D printing accessibility for professionals. Not only does its new LCD technology instead of the company standard SLA makes it much faster but it more affordable that other professional resin solutions.

In its shift from SLA to LCD, Formlabs brings its years of innovation with it in terms of what customers have always liked: an integrated ecosystem of hardware (including post-processing machines), software, materials, automation, and support.

The the trade-off for Form 4’s LCD speed is a small difference in print resolution when comparing the Form 4 to the Form 3+ (50 microns in the XY vs. 25 microns). The Form 4, being LCD technology, lists resolution slightly differently – it has a 50-micron pixel size, yet, couple this with “pixel smoothing,” which is technology in a printer’s slicing software, and the resolution of the Form 4 should effectively equal the Form 3+ in most applications.

In addition to the Form 4, there’s the also-new Form 4B ($6,300) for dental and medical applications.

Tech Specs & Price

- Technology: LCD (Formlabs is calling its take on LCD “Low Force Display, LFD”)

- Build Volume: 200 x 125 x 210 mm

- Layer thickness (Z resolution): 25 – 300 microns

- XY resolution: 50 microns

- Print Speed: up to 100 mm / hour

- Camera: Built-in

- Materials: 23 validated, optional license for open material platform

- Price: The Form 4: $4,500, Form 4B: $6,300

Nikon's Lasermeister LM300A DED

(Apr. 10, 2024) Nikon (yes, the camera company, which has been in additive manufacturing since 2019 and acquired SLM Solutions in 2023) just released its “next-generation metal additive manufacturing system”, the Lasermeister LM300A, which is a laser directed energy deposition (DED) metal 3D printer. DED is largely used for 3D printing complex structures, adding features to existing parts, and repair.

Considering it’s German sounding name, the Lasermeister LM300A system was likely already in development at SLA Solutions, which is based in Germany, prior to the merger.

This system is mainly targeting researchers and industrial R&D, the company says. What’s exciting about this offering is the accompanying 3D scanner unity, the Lasermeister SB100. By simply placing a workpiece, such as a worn-out blade, inside the scan chamber, the module begins to scan and measure the workpiece. It then compares its current actual shape with its ideal CAD model to extract the difference, using a built-in scanning feature. The machine then automatically generates the tool path data for repair specific to each damaged or worn-out workpiece. This tool path is fed to the LM300A 3D printer for repair of the part.

Once the additive process is completed, the workpiece can be placed back into SB100, where it will scan and inspect to confirm the repair was performed to its ideal model.

Tech Specs & Price

- Technology: Directed energy deposition

- Build Volume: 297 x 210 x 400 mm

- Accuracy: XY -0mm / +0.5 mm, Z +0.5 / +1.5 mm

- Chamber: Inert gas, nitrogen gas or argon

- Materials: Ni625, Ni718, Stainless Steel, Titanium, +more

- Price: >$500,000

EOS' New M 290 1kW Metal LPBF

(Mar. 30, 2024) The large 3D printer maker EOS officially launched its newest metal laser powder bed fusion machine initially focusing on copper (CuCp and CuCrZr).

M 290s from EOS have been popular for years and the boost in laser power to 1,000 Watts isn’t completely unexpected. The manufacturer has been custom-fitting its machines with this power at its AMCM customization wing and decided it was time to let this unit out into the wild particularly to cater to customers in space, energy, and mobility.

One early adopter, GBZ Mannheim, a German tool and part maker, has been using the machine to fabricate copper inductors with more optimized cooling channels.

Nearly everything else about the M 290 1kW is the same as the older version with the 400-watt fiber laser except for a slight smaller laser focus diameter (90 µm vs. 100 µm)

Tech Specs & Price

- Technology: Metal laser powder bed fusion

- Build Volume: 250 x 250 x 325 mm

- Laser: 1 x 1,000 W

- Scan Speed: up to 7.0 m/s

- Laser Diameter: 100 µm

- Software: EOS Build/Build+, EOS Smart Monitoring, EOS Data Insights, EOS Systems Suite

- Price: >$500,000

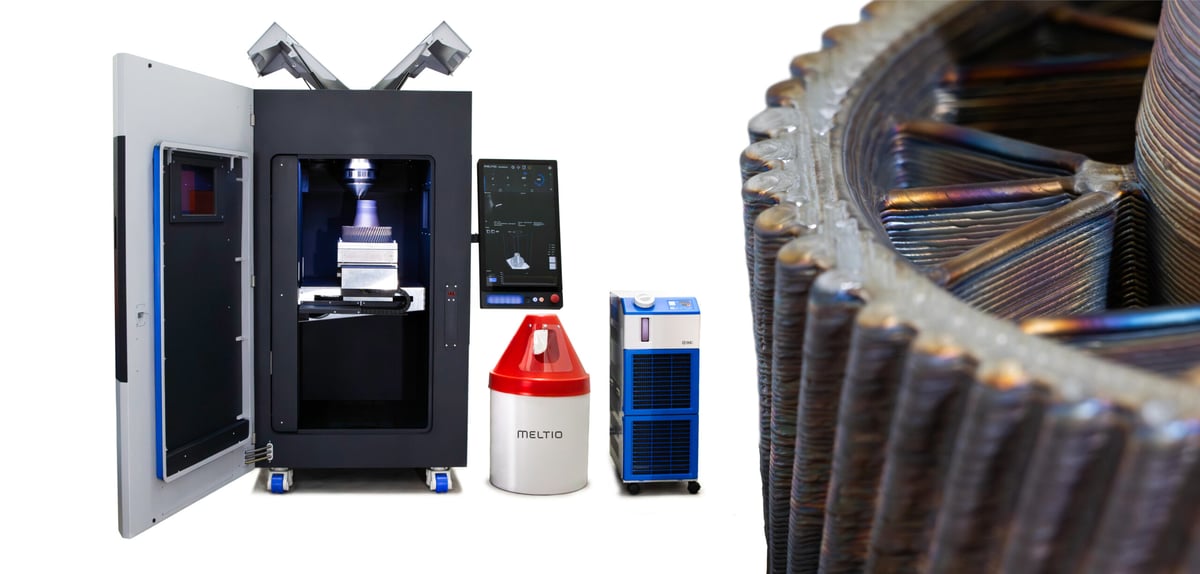

Meltio's New M600 Laser Wire DED

(Mar. 12, 2024) Meltio, which makes a host of wire-laser metal deposition systems, aims to make the technology less intimidating and more accessible for machine shops and small to mid-size manufacturers.

The new M600 offers a range of automatic features that Meltio hopes will ease the introduction of the technology into more places, outside of its current niche areas, where it can offer increased metal part production speed with less waste.

Designed to perform 24/7 with minimal operator interaction, the M600 is a 3-axis 3D printer that uses common welding wire as its feedstock, which is much cheaper than metal powder and safer to handle.

Meltio says the material properties of parts from the M600 are comparable to conventionally manufactured parts.

New for laser DED technology is Meltio’s use of a blue laser it says increases printing speed while reducing energy consumption. This short wavelength light is better for reflective materials, such as copper and aluminum alloys, and, combining this with the enclosed printer’s fully inert workspace, expands the available range of materials. The DMG Mori Lasertec machines also feature a blue laser but use metal powder instead of wire.

The laser head, which is calibrated at the factory, not by users, includes new sensors for monitoring the printing process.

The M600 is not only for fabricating parts from scratch but enable you to add or repair existing parts.

Meltio Horizon, is the dedicated slicer for the Meltio M600 and the backbone to its automation. It features a simpler profile selection and premade profiles that cover a large range of geometries and qualities. Workers can select a stored presets and the machine workspace adjusts automatically. Engineers can use the slicer to also configure different sections of the build for print quality and speed and generate infills, including gyroid lattices.

Tech Specs & Price

- Technology: wire laser direct energy deposition (L-DED)

- Build Volume: 300 x 400 x 600 mm

- Laser Type: 9x direct diode blue laser (450 nm wavelength)

- Materials: Metal wire (0.8 – 1.2 mm)

- Price: TBD

Farsoon's new FS721M-8-CAMS Metal LPBF

(Mar. 11, 2024) Farsoon, the large Chinese manufacturer of both metal and polymer laser powder bed fusion 3D printers, just launched its latest edition, the FS721M-8-CAMS, whew, that’s a mouthful. We’ll just call it Cams, which stands for Continuous Additive Manufacturing Solution.

This metal LPBF machine features an internal conveyor system, which the company says opens up new potential for series production with increased automation.

Integrating eight 500W or 1000W lasers, Cams automatically transfers a completed build unit to an “inert breakout station” and loads a second build unit to start another print job. Billed as “continuous production capability” this system ensures minimal machine downtime between build jobs.

In addition to the print automation, the powder handling is also automated. The closed-loop powder handling system integrates multiple powder processes, including powder recycling, storage, sieving, and new powder supply.

Print speed on the Cams can be up to 300 cm3 per hour.

Hardware advancements on the Cams over the company other metal LPBF machines include an updated chamber design with “multi-layer gas flow” and a new recoater design to improve powder surface flatness and consistency throughout the build area.

Like all Farsoon systems, the Cams is powered by Farsoon’s MakeStar software that offers build process control and real-time monitoring of the build environment, including laser power, air flow, temperature, and humidity. In-chamber cameras monitor and record each layer for build quality.

Tech Specs & Price

- Technology: metal laser powder bed fusion (M-LPBF)

- Build Volume: 720 x 420 x 390 mm

- Min. layer thickness: 0.02 mm

- Max. Laser Scanning Speed: 10 m/s

- Laser Type: 8 x 500W or 8 x 1000W

- Inert Gas: Argon/Nitrogen at 6-8 l/min

- Materials: Stainless steels 316L & 17-4PH, TA15, Ti6Al4V, AlSi10Mg, Al5250

- Price: TBD

Prusa's New Pro HT90 FDM

(Mar. 5, 2024) The long-awaited Pro HT90 FDM from Prusa Research is finally available to order, but not shipping until June. This FDM 3D printer targets engineers, as opposed to Prusa’s mainly consumer customer base, who want to 3D printing functional prototypes and end-use parts made from engineering grade materials, such as PEI and carbon-fiber-infused PEKK.

The HT90 is the company’s first delta kinematic 3D printer standing apart from its extensive line of Cartesian-style 3D printers. This type of printer can have faster changes in direction and quicker movements than most Cartesian machines. Prusa says the Pro HT90’s acceleration reaches up to 20,000 mm/s², but the company hasn’t release an actual print speed.

Describing speed in a more practical way, Prusa says the HT90 can deposit 1kg of PETG or ABS filament in just eight hours.

In another first for Prusa, the HT90 is fully insulated and enclosed with an actively heated and cooled chamber. The heat — from the heated bed to 155ºC, heated nozzle to 500ºC, and the chamber heater to 90ºC — makes printing with industrial materials more predictable, while the active cooling ensures that, when you’re printing with PLA, you don’t have to keep the door open to prevent overheating. This feature lets you take full advantage of the professional-grade HEPA air filter for every print.

Tech Specs & Price

- Technology: FDM

- Build Volume: Ø 300 x 400 mm

- Max. Nozzle Temp.: 500°C

- Max. chamber temp.: 90°C

- Max. bed temp.: 155°C

- Print Preparation: Prusa Slicer

- Price: $10,000

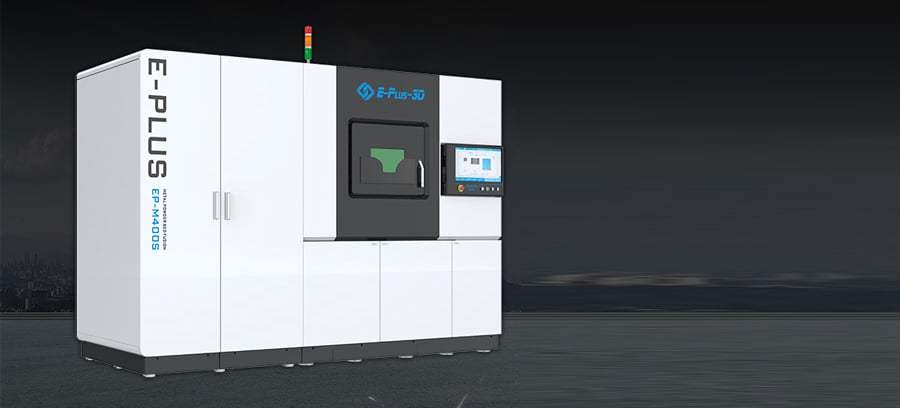

Eplus3D's New EP-M400S Metal LPBF

(Jan. 31, 2024) Eplus3D, a maker of metal laser powder bed fusion 3D printers, just launched a new edition of its quad-laser printer originally launched in April 2023. The EP-M400S builds on the success of the EP-M400, the company says. This new model brings “significant enhancements” including a new top feeding powder hopper and bi-directional powder re-coating, which reduces powder-spreading time by up to 30%.

The EP-M400S is also 10% smaller than the non-S version while reducing the build volume just a touch from 405 x 405 x 450 mm to 400 x 400 x 450 mm. The laser spot size is a touch smaller (70 µm vs the previous 80 µm) Eplus3D says new features added to the EP-M400S provide easier access for cleaning and maintenance locations on the machine. Otherwise, the specs of the EP-M400S are pretty much the same as the EP-M400.

Tech Specs & Price

- Technology: Metal Laser Powder Bed Fusion (LPBF)

- Build Volume: 400 x 400 x 450 mm

- Laser: 1, 2, 3, or 4 fiber lasers with multiple power levels (500W, 700W, and 1KW) for each

- Laser Spot Size: 70 – 120 µm

- Max Scan Speed: 8 m/s

- Layer Thickness: 20 – 120 μm

- Materials: Open. Titanium Alloy, Aluminium Alloy, Nickel Alloy, Maraging Steel, Stainless Steel, Cobalt Chrome, Copper Alloy, and more.

- Gas Supply: Ar/N₂

- Software: Eplus3D EPHatch

- Price: not yet available

CreatBot's New D1000 FDM

(Jan. 03, 2024) The new D1000 large-volume industrial FDM 3D printer from CreatBot is the latest machine to join the square-meter club with its 1,000 x 1,000 x 1,000 mm build volume.

CreatBot’s D1000 doesn’t just print large objects, it also supports large-sized spools of filaments, including PLA, ABS, ASA, PC, Nylon, PA-CF, so you can print big models without worrying about having to replace the filament in the middle of a project.

The D1000 also sports a new auto-rising dual extruder hot-end kit that enables the nozzle temperature to reach up to 420℃. There’s a convenient magnetic build plate for easy removal of large prints, a chamber that reaches 60°C, and a HEPA air filter.

Tech Specs & Price

- Technology: Fused Deposition Modeling (FDM)

- Build Volume: 1,000 x 1,000 x 1,000 mm

- Max. Nozzle Temp.: 420ºC

- Max. Bed Temp.: 100ºC

- Max. Chamber Temp.: 60ºC

- Max. Print Speed: 120 mm/s

- Min. Layer Height: 50 μm

- Materials: Open

- Software: CreatWare, Simplify 3D, Cura, Slic3r, etc.

- Price: Aprox. $45,000

License: The text of "All the New Professional 3D Printers Launched in 2024" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.