With the growing adoption of 3D printing technologies across small companies and large enterprises, a new challenge has emerged among businesses that are shifting to digital manufacturing: tracking and managing 3D printed part production.

It has become too complicated to manage the process of part design, ordering, creation, post-processing, and delivery without a software solution that covers the end-to-end workflow. Manufacturing execution systems (MES) are nothing new to traditional manufacturing, but they aren’t ideally suited to additive manufacturing, which has different perimeters, materials, and processes. Enter AM workflow software. These solutions (either standalone or integrated into your existing MES) are essential to streamline the AM production process and integrate it within your company’s digital transformation.

As additive manufacturing becomes true production manufacturing, manufacturing execution systems can take a lot of the growing pains out of 3D printing at scale. Whether your company is 3D printing a few dozen parts a year at one location or thousands of different products on fleets of 3D printers across the globe, there’s a range of software solutions available today to help you keep track of it all.

These workflow solutions are far more robust than just printer farm software (although we do detail those, too, down below). They enable companies to manage what is being printed, where, when, for what, and by who, with robust data on print perimeters, material usage, and part performance leading to repeatable and reliable part production whether you’re a 3D printing service provider, an automaker, or a 3D printing hub for a large organization.

Prove Additive Manufacturing’s ROI

If your company got the green light to incorporate additive manufacturing into its processes, your going to need to prove the ROI. Only with data can you show how much money 3D printing is costing and saving your organization. Depending on the robustness of your software solution, you can calculate how much a part or batch of parts will cost in time and materials before it’s printed and the actual time and materials, including post-processing, of the parts. Some solutions integrate directly with your 3D printer so you can monitor printing progress, and detect and log print failures, which contribute to cost.

Potentially any business with more than a few 3D printers could benefit from software that tracks prints, printers, resources, and costs, but the companies getting the most out of workflow software for AM currently include 3D printing service bureaus, automotive manufacturers, and traditional part manufacturers that have introduced additive manufacturing to their shop floor.

Traditional manufacturing MES solutions can be tricky to customize for the uniqueness of additive manufacturing. Compared to injection molding or CNC machining, 3D printing can include more or fewer steps, different materials, and post processing. Plus, your existing MES may or may not integrate with your 3D printing software. Of course, you don’t want a piece of software that’s unique to additive manufacturing. Many of the products we highlight below can integrate with your current MES so you can seamlessly track and trace your additive manufacturing operations alongside your traditional ones.

Who Should Consider Integrating AM Workflow Software?

Any operation that produces more than a dozen parts on a weekly basis should consider software that optimizes the process. Whether you’re running a university print farm with a dozen machines and hundreds of users or managing a global spare parts operation with various 3D printing technologies in different locations, AM workflow software can ensure the operation is agile and accountable. With the shift to digital manufacturing expected to grow even further in the future, you’ll need a software platform to manage and control the entire process.

The Benefits of AM Software

The main advantage of using professional AM software is managing the process within one tool. In practice, it means connecting all an organization’s 3D printers on one platform, thus enabling users to better access and utilize digital manufacturing. When this is the case, there are several benefits, including:

- Monitoring orders from quotation all the way through to production

- Better cost estimation

- Increasing efficiency with better traceability

- Higher machine monitoring and performance

- Better production planning

- Better quality assurance

- Better repeatability and reliability

- Increased IP and data security

- Reducing human errors

Once such a tool is integrated, the limitations to accelerating AM are removed and the main element moves to a different key success factor, namely finding the right applications to enable further shifting from traditional manufacturing methods to AM technologies.

Making the First Step

Adopting AM workflow software is not something you do overnight. First, it requires the important step of analyzing your current and future bottlenecks to understand if a management software tool can help you solve the challenges you are facing, or if AM workflow software would be an overkill solution for now.

Consider using the input of external consulting firms that can offer an outside perspective, bringing essential experience and knowledge to the table to tailor the right solution for each organization according to its specific needs.

Many of the software providers listed below have case studies on their websites and will provide customers you can talk with about their products.

Buyer's Guide: 3D Printing Workflow and MES Software

Below are the top products on the market that aim to automate, streamline, and standardize your 3D printing so you can grow your business. These solutions tackle the complexity of producing identical 3D parts, sometimes in separate facilities, which requires qualifying materials, setting system calibrations, pre-defining parameters, and constantly training engineering staff. They enable users to save time, cut production costs, waste lass materials, and ensure quality prints. Let’s take a look.

3YourMind

This enterprise additive manufacturing execution system from 3YourMind is aimed at companies, from tooling manufacturers to automotive OEMs, with a catalog of parts that need to be printed by various departments and stakeholders. The software enables “the full digitization of the shop floor”, the company says and features the ability to create unscheduled jobs, and schedule post-processing independently.

In 2021, the company won a contract from the Naval Information Warfare Center (NIWC) Pacific to provide the US Navy with a seamless digital production workflow to enable distributed additive manufacturing. In late 2022, 3YourMind announced a partnership with Werk24, an AI company that can analyze 2D drawings to determine if they would meet the criteria of parts for on-demand additive manufacturing.

The latest version of the software boasts some improvements aimed at helping companies 3D print more in less time, make ordering 3D parts faster and more intuitive, and accelerate up-loading time of orders along with mass-production scheduling.

The 3YourMind suite includes a Product Lifecycle Management tool, an Enterprise Resource Planning tool, and a Manufacturing Execution System tool that works together and integrates with Stratasys and Ultimaker.

Some of the stand-out features include the ability to compare available materials and technologies to select the ideal part. The ordering system provides an instant comparison of options based on a 3D file analysis, part specifications, production selections and technical requirements. The software displays the choices for production in a single clear overview so you can optimize for speed, cost, or machine utilization and maximize your output. The “digital marketplace” feature even enables you to compare internal and external suppliers and choose based on speed, location, or cost.

Materialise CO-AM

Global additive manufacturing software maker and service company Materialise introduced CO-AM in 2022 and is working toward a full rollout in 2023.

CO-AM is an open software platform to manage the additive manufacturing production process from order entry to quality assurance. CO-AM gives manufacturers cloud-based access to software tools that allow them to plan, manage, and optimize every stage of their AM operations, the company says.

The Materialise CO-AM platform offers an open software architecture that provides manufacturing companies direct access to multiple hardware technologies and their preferred tools. The goal is to build an end-to-end manufacturing solution that creates competitive advantages for individual companies and empowers entire industries, such as aerospace, automotive, consumer, medical, and energy, the company says. The platform can even estimate the costs of 3D parts, recommending the most suitable materials to be used based on the parts’ functional requirements.

Materialise plans to offer more than 25 software applications on its CO-AM platform, including seamless integration with Magics; AM Watch for shopfloor data collection, and its Build Processors for connectivity with more than 150 3D printing systems. The company will also open the platform to independent software vendors and has already onboarded several third-party applications, including AM-Flow and Castor, the software that automates the process of identifying parts for additive manufacturing.

One notable feature is the platform’s security. The product suite encrypts, distributes, and traces the flow of digital parts, preventing counterfeits and ensuring that maliciously or inadvertently modified, substandard, or uncertified parts cannot enter the physical supply chain.

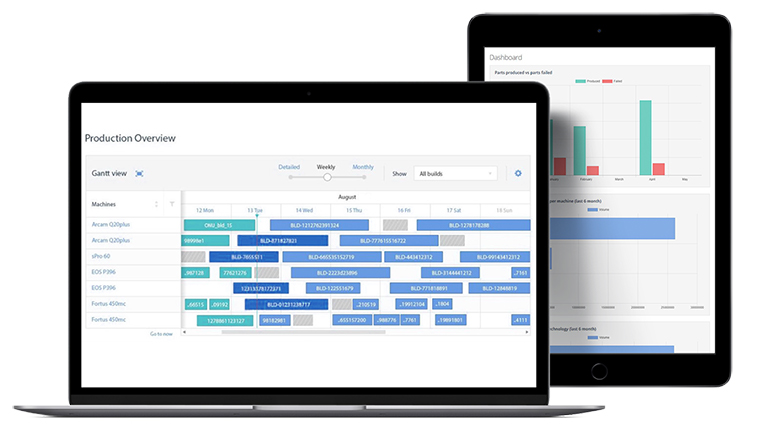

AMFG

London-based AMFG provides MES and workflow software for additive manufacturing to customers in dozens of countries and a range of industries. One of the company’s major focal points is helping companies integrate additive manufacturing into their wider manufacturing processes and scale their AM operations.

AMFG’s software features a series of modules that the company collects in bundled solutions to address the needs of companies in different sectors, such as rapid prototyping, spare parts, serial production, or those that are 3D printing service bureaus. Its “customizable workflow automation solutions” gives you the flexibility to build a software platform to fit your need, AMFG says.

The order management module, for example, can help companies manage and process all orders centrally, generate work plans, provide accurate job costing, and ensure that delivery deadlines are met with real-time status tracking. The post-processing and quality management module coordinates all post-processing and quality assurance steps needed to fulfill project requirements including generating barcodes in job sheets to identify parts quickly.

Other AMFG MES and workflow modules include:

- Digital Inventory

- Ordering Portal

- Supply Chain Management

- Production Planning & Scheduling

- Machine Connectivity

- Integrations & Security

- Analytics & Reporting

Among the customers AMFG showcases on its website is the Oslo School of Architecture and Design, which needed an efficient way to manage its request handling and production management processes from students using additive manufacturing as part of the curriculum and within its research department. Another case study features the 3D printing service Parts on Demand, and its need to improve options to receive customer orders through all channels (website, email and telephone) and translate those into comprehensive, accurate quotes.

AMFG’s MES integrates with a wide range of enterprise software (SAP, Oracle, Microsoft), payment software, logistics (DHL, UPS, FedEx), design (Autodesk, GrabCAD), and the top AM printer manufacturers including Stratasys.

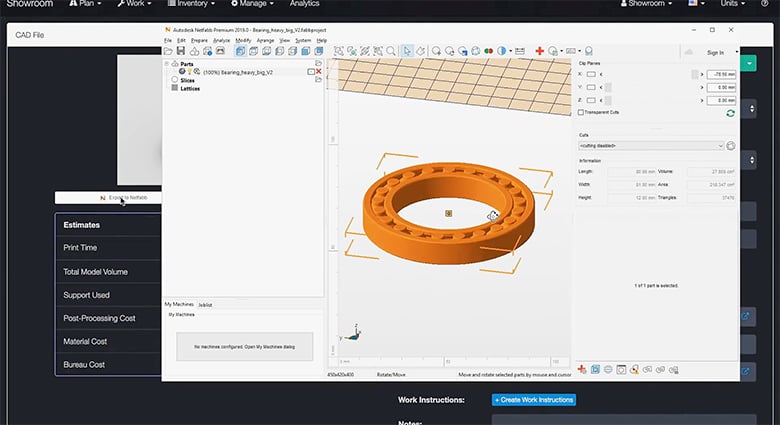

Authentise aMES/ FlowsAM

Whether you’re making prototypes or production parts, American software publisher Authentise helps you manage your processes.

The Authentise MES Platform for OEMs (there’s also a platform for 3D printing service bureaus) is a robust, multi-location reporting, compliance, and process tool featuring customized dashboards, order summaries, and operation-wide analytics to give you oversight into what your company is 3D printing, where, how, and how much it costs.

This platform is for manufacturers churning out hundreds or thousands of 3D printed parts. It can help you stay on top of raw material use, iterations, print files, and outsourcing. Optional add-ons cover a range of industry specifics, including the material handling module that tracks and reorders materials used in production, the on-process monitoring module that detects print failure with computer vision and uses machine learning to predict maintenance, and the mesh healing tool that repairs models.

Authentise boasts a long list of partnerships and integrations with other AM-related software. In 2020, it announced a collaboration with Nebumind, the maker of manufacturing data visualization and analytics tools, to help users identify problem zones of each part more easily and lead to less time-intensive and more accurate inspections, the companies say. In late 2021, Authentise announced a collaboration with the Solukon Digital Factory Tool for real-time monitoring of automated powder removal.

Authentise also now partners with start-up Addiguru to incorporate real-time additive manufacturing process monitoring powered by computer vision and artificial intelligence. This will enable users to be alerted in real-time if any potential issues arise throughout the print workflow.

In late 2022, Authentise teased a new version of its MES software rebranded at Authentise FlowsAM that will be generally available in 2023 although an early adopter program is now open for select customers.

This MES boasts some close integrations with NetFabb, Siemens, Fusion 360, Oracle, and other enterprise software, as well as with existing IT systems, such as Single Sign-On (SSO), and engineering tools, such as Product Lifecycle Management (PLM) and Enterprise Resource Planning (ERP) tools.

Among the printers Authentise integrates with are EOS, Stratasys, Renshaw, Carbon, 3D Systems, SLM, Trumpf, and Ultimaker.

Other features:

- Print Planning and Scheduling

- On-Demand Digital Parts Catalog

- Tracks Machine Status and Error Messages

- Quality Assurance and Reporting

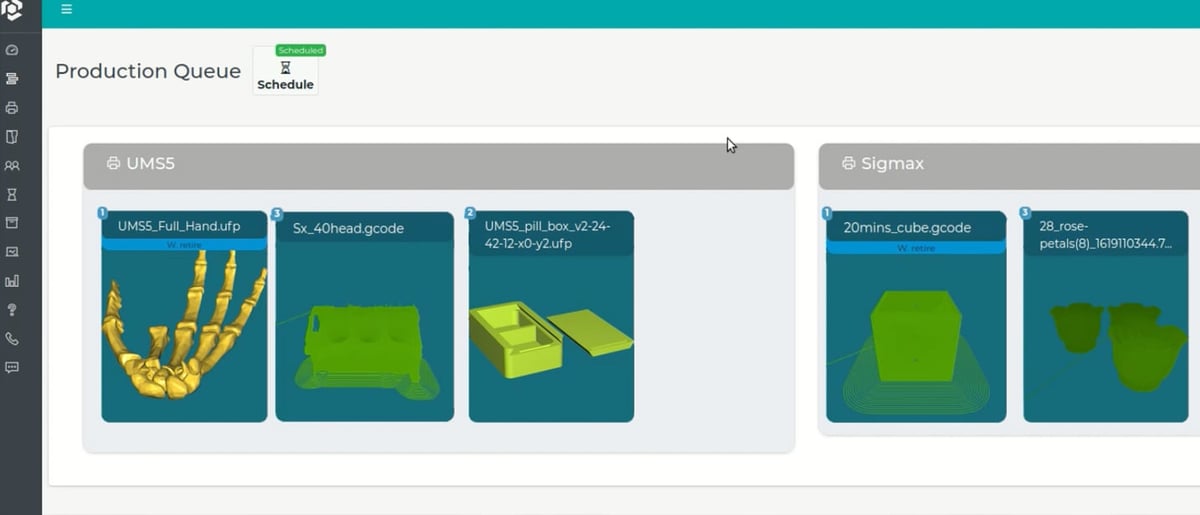

Oqton Manufacturing OS

Oqton, a 3D Systems company, offers a robust end-to-end solution it calls a “one-stop Industry 4.0 solution for the entire market”.

Oqton’s Manufacturing OS MES platform combines several key functions of software used in 3D printing (CAD, PLM, CAM, IOT, MES, QMS) into a single platform for additive manufacturing, robotic welding, and CNC machining.

Oqton’s cloud-based additive manufacturing platform aims to create a fully automated manufacturing solution for industries where that makes sense. The company says it has already achieved 100% automation in the dental and jewelry verticals, resulting in a 30% overall cost reduction.

The Oqton features robust but scaleable build preparation platform options that include process simulation, build orientation optimization, and predictive build time. The MES tool is linked to a cloud-based IoT interface that allows you to access, monitor, control, and automate technologies remotely and across multiple sites. Other features include order capture and tracking, quality management, and process scheduling, plus the entire system learns from usage and automatically suggests classifications, orientations, and support strategies to further reduce engineering time spent on repetitive tasks.

After its acquisition by 3D Systems, Oqton’s portfolio now includes 3D Systems’ software 3DXpert, 3D Sprint, its Geomagic portfolio, and Additive Works’ Amphyon, as both standalone products as well as optional add-ons to the Oqton MOS platform. By building one consolidated software portfolio, Oqton intends to make these disparate tools cloud-connected to enable seamless workflows to provide a unified solution. 3DXpert was just updated to incorporate Hexagon’s HxGN Emendate engine for topology optimization.

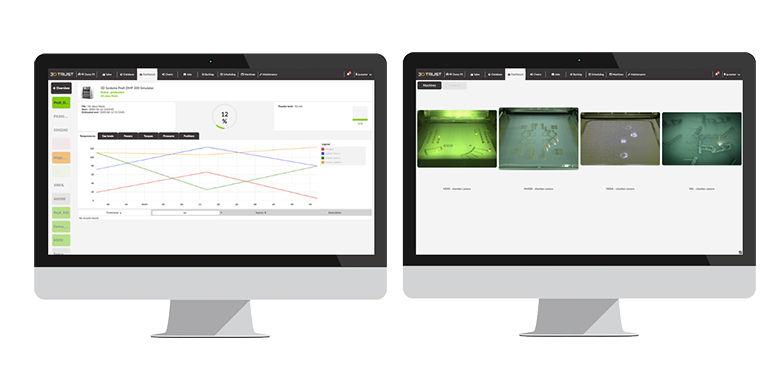

3DTrust MES

European start-up 3DTrust offers an additive manufacturing workflow software platform aimed at helping companies optimize their 3D printing operations and address the challenges of ramping-up production. The focus here is on increasing the productivity of your 3D printer fleet and improving traceability and quality with machine monitoring and traceable data along the AM value chain.

3DTrust centralizes requests from internal and external customers, generates routing for each part and provides quotes. It can track orders’ progress on the shopfloor with real-time status while collecting and analyzing printer sensor data during production to anticipate print failures and improve performances. The data is stored for traceability and can be exported if needed to meet European or FDA regulations. The software manages and monitors production on most main industrial printer brands.

3DTrust MES enables you to keep and eye on the health of your 3D printer fleet with trackable maintenance history, print fail stats, the quantity of parts printed, and the amount of material consumed. With this data, you can better identify the bottlenecks in your shop floor and take the right action to improve your productivity.

In addition to its flagship product, 3DTrust has just released a powder management solution.

By using the powder mobile app, you can scan material containers in your shop floor and perform actions such as mixing, sampling, and recycling to create the digital traceability of your powders, something that’s essential for regulated industries. On the browser application, you can visualize your inventory and powder’s genealogy.

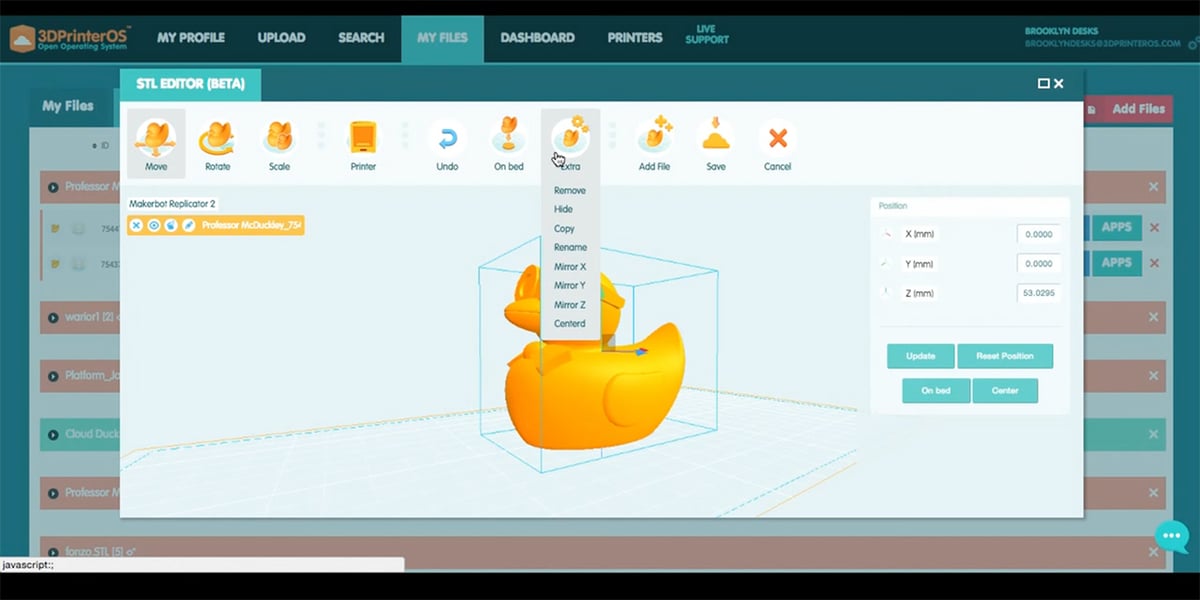

3DPrinterOS

3DPrinterOS (a Solution by 3D Control Systems) is a scalable platform to manage 3D printers and users. The company says its system solves the fragmentation of many disparate 3D printers and their associated software enabling full visibility and transparency into who is printing what, which machines need repair, what analytics are being produced, material inventory levels, errors, audit controls, filament usage, and more. The system can also monitor real time prints and share projects and printers with your colleagues.

3DPrinterOS is an operating system that allows you to run multiple slicers and software on one platform. It can be deployed in the cloud and on local servers.

3DPrinterOS features order management, supply chain management, analytics and reporting, digital inventory, post-processing and quality management, production planning and scheduling, and custom AM workflows.

When it comes to integration, 3DPrinterOS says more than 1,500 machines are supported by different levels of integration, along with integration with Oracle, SAP, Salesforce, and Microsoft Dynamics.

Fabpilot

Fabpilot is an end-to-end additive manufacturing software suite built to support businesses that 3D print – at whatever scale they operate. Originally created by the 3D printing service Sculpteo as its in-house solution, Fabpilot features a few file preparation features some other MES providers don’t, such as its own STL file repair, lattice infill generation, 3D file analysis, and part nesting tools.

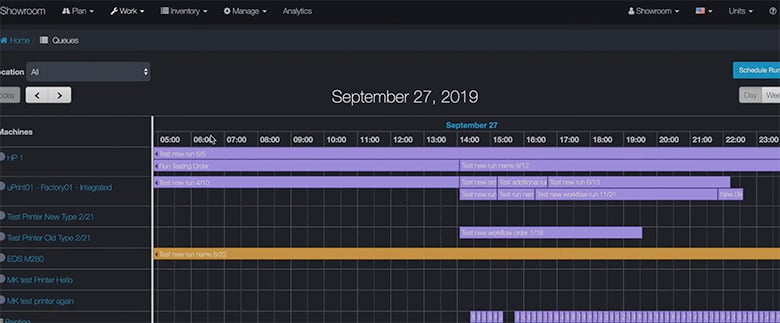

Fabpilot also boasts a job management interface, part tracking, and machine scheduling. Coming soon, according to its website, are new modules that will feature insights into the KPIs that matter most to your specific AM workflow, and machine learning to help you optimize your production and work more efficiently.

This Software as a Service (SaaS) solution was designed in 2018 with ease-of-use in mind and comes in three levels; starter, professional, and enterprise. At just $99 per month for the starter version, Fabpilot is one of the more affordable solutions on the market and also offers a free trial.

According to Sculpteo, Fabpilot has helped to lower 3D production failure rates by 50%. Among the customers it showcases on its website is the 3D printing company 3Faktur, which says it saves 1 hour of manual work per production run and reported a 2% increase in the packing rate with by using Fabpilot’s nesting tool.

Print&Go

If you have a fleet of desktop FDMs to manage, start-up Print&Go offers a solution to automate your processes so your print farm can run unassisted.

With Print&Go you can monitor your 3D printers, controlling them remotely and in real time. It enables you to plan production by analyzing manufacturing costs and traceability, as well as to manage stock by optimizing material consumption and production times. Print&Go software works with several brands of 3D printers on the market, including Ultimaker, Raise3D, BCN3D, and Prusa.

Starting at an affordable €35 a month, the modular solution includes options for maintenance, scheduling, reporting and AI.

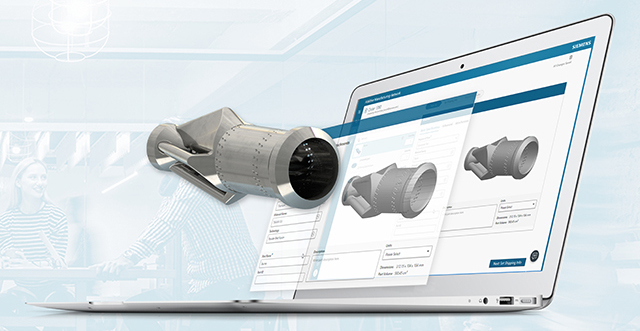

Siemens NX for Manufacturing

If you already use Siemens software in your design and manufacturing ecosystem, you may already know about NX for Manufacturing.

As opposed to a workflow management systems that sits in between your design and printing applications, the NX software suite covers it all. It’s a robust end-to-end part manufacturing solution for large enterprises that includes everything you need to design for AM – including generative engineering, build preparation, and build simulation – all the way through production and quality control to post processing.

The workflow management tools in NX are equally robust in their own, and include an order management system called Siemens’ Additive Manufacturing Network (AMN) that provides an online order-to-delivery collaboration platform to co-create AM parts with an ecosystem of outside AM manufacturers.

There’s also the Siemens Opcenter solution that enables you to manage your own additive manufacturing production – schedule, execute, and monitor AM production with full operational visibility. You can also use the Opcenter solutions to visualize material flow throughout a facility to ensure that the proper mix of recycled and virgin material is being used for the various print jobs executing throughout the factory. Also included are quality checks and analytics that provides the ability to monitor the additive manufacturing process, analyze the resulting data, and act upon that data with part and process improvements. This close feedback loop lets you feed insights back into upstream phases of the additive manufacturing process.

NX is not limited to just 3D printers. You can program CNC machine tools, control robotic cells, and monitor quality all on the same software system.

Solutions for Makers & Small 3D Printing Businesses

If the solutions above seem overkill and all you want to do is network your printers, schedule prints, and monitor print progress, whether you have two or 20 machine, there are several reliable solutions. Make no mistake, these are not just for hobbyists and may just feature all the tools your enterprise needs. The trick is finding a solution that’s compatible with your brand of 3D printers, so be sure to investigate. Also, we’re seeing more printer manufacturers come out with their own print farm solutions for, understandably, only their brand machines.

There’s a breed of workflow software aimed at individuals and small companies looking to sell what they print. If you’re one of these small businesses, you know that order management can be a huge hassle. Several solutions available cater to the smaller, customer-focused operation, with features including a customer-facing portal and an automated quote system, and a way to track completed orders, parts produced, acquired clients, and paid invoices.

California-based DigiFabster, is a sales automation company for custom manufacturing businesses. Its solution provides web-based software empowering job shop manufacturers (3D printing, CNC milling, injection molding, etc.) to streamline quote generation and e-commerce sales and automate a lot of the customer management and production processes that can take up your time.

AutoFarm3D: software that enables you to check system vitals and statistics on a handy dashboard so you can monitor your farm, detect print failures, and enable part traceability to improve and log results, all with live alerts to your mobile.

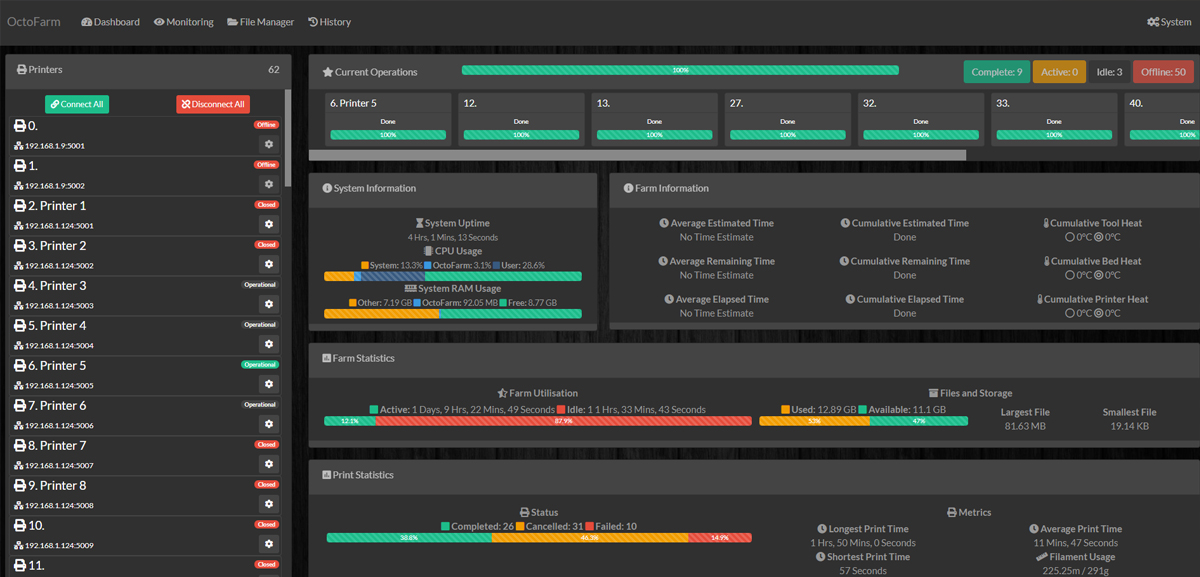

OctoFarm: a free, open-source, and user-developed interface that allows you to control and monitor multiple 3D printers on a single Raspberry Pi. You can check on your multiple printers on a single screen, including sending and monitoring prints.

AstroPrint: a cloud-based printer hosting solution that allows you to monitor and manage multiple 3D printers, store files in the cloud, slice, and monitor analytics. There are several paid account levels, but the free tier offers enough for you to comfortably manage your printer or printers remotely. Printer manufacturer BCN3D acquired AstroPrint in 2021 and plants to also launch a new BCN3D Cloud platform.

BuildBee: a solution that offers to take the sting out of 3D printing. Upload, slice, queue, share, monitor, and manage a fleet from any device, anywhere.

RaiseCloud: a web-based 3D printing platform that remotely controls, monitors, and reports your entire print production progress at a glance. Operates with Raise3D printers and any third-party machines running the OctoPrint interface.

Brand-Specific Printer Fleet Solutions

Ideal for schools, universities, and other places where there’s a fleet of a single brand of 3D printers, are these proprietary solutions. These providers say their products are always kept updated and often are included with the purchase of several machines.

Lead image source: Source: Oqton

License: The text of "Top 3D Printing Workflow & MES Software" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.