Titanium is one of the most commonly used metals in additive manufacturing, widely employed in aerospace, joint replacements and surgical tools, race cars and bicycle frames, electronics, and other high-performance products.

Titanium and titanium-based alloys are prized for high mechanical strength, a high strength-to-weight ratio, and better corrosion resistance than stainless steels. The material makes rockets and planes lighter, which saves fuel and increases payload capacity. It also makes for lighter weight electronics, such as smart phones and VR goggles. Likewise for medical implants. And, when you couple titanium’s inherent qualities with the unique features available when you 3D print with it, the advantages multiply.

3D printing enables more efficient manufacturing of this costly metal with lower consumption of raw material and lower waste. As an additive technology, metal 3D printing typically uses only the necessary amount of material for building a part, plus a relatively low amount for support structures.

3D printing also enables complex designs, such as internal channels, and hollow or lattice infilled parts to reduce weight, that are not possible with any other manufacturing method. Because there are no molds or tooling, titanium 3D printing enables cost-effective one-of-a-kind parts, such as patient-specific implants, prototypes, and research tools.

There are countless examples of 3D printed titanium advancing manufacturing, healthcare, space exploration, and much more. Let’s take a look at why titanium is so well suited to additive manufacturing and where it is being used today.

Who's 3D Printing Titanium and for What?

Who is 3D printing with titanium today? It’s a broad collection of manufacturers making everything from medical devices, high-performance bicycles, luxury watches, and consumer electronics. What they all have in common is a desire to deliver a lighweight and strong product with innovative, often custom, design.

Precision Products & Electronics

3D printing can create very thin-walled, intricate, and complex titanium parts, which is why it’s used for watch cases, such as the Panerai and Holthinrichs timepieces pictured above and rumored to be an upcoming part of the Apple Watch Ultra.

In 2023, smartphone maker Honor introduced the new folding Magic V2 featuring a 3D printed titanium hinge shift cover that’s lighter than the previous aluminum version and 150% stronger. The company says this this small titanium piece, which can be 3D printed in the tens of thousands, is the key to the product’s durable and smooth folding and unfolding.

Medical & Dental Implants

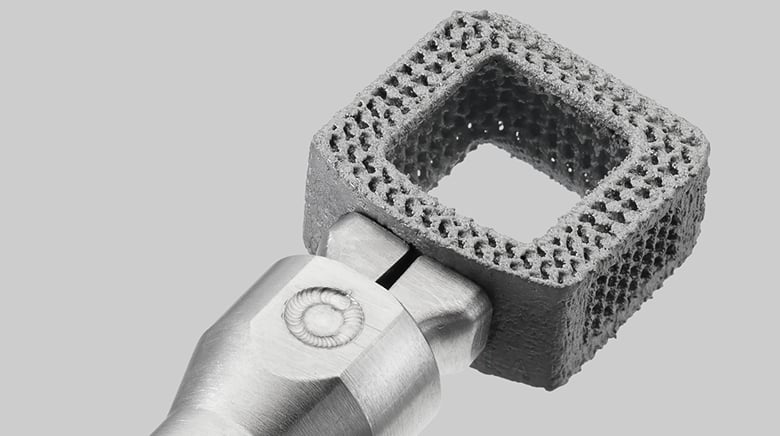

In the medical industry, 3D printed titanium implants are successful across spine, hip, knee, and extremity applications due to the metal’s inherent biocompatibility and good mechanical properties combined with 3D printing’s ability to tailor porous structures — which enable bone integration — and mass customization for better patient outcomes.

3D printed titanium implants are gaining in both regulatory approval and demand. Because most medical implants are manufactured to cover large groups of people with the same condition, they aren’t an ideal fit for everyone. People suffering from rare conditions are often left out. Now, with 3D printing, it is possible to produce implants designed exclusively for individual patients.

In 2023, a surgeon in England performed four wrist surgeries in the same day to correct a deformity of previously broken wrist bones with patient-specific 3D printed titanium plates. “Once this planning process has occurred, the bespoke plate is printed using powdered titanium, then tested, shipped to the UK and sterilized at County hospital ready for surgery,” says Dr. Akshay Malhotra, Consultant Orthopedic Surgeon and Clinical Lead for Hand and Wrist Surgery at University Hospitals of North Midlands.

Presented with a cancer patient whose tumor was destroying his ribcage, doctors at Manipal Hospitals in India turned to 3D printed titanium in 2022. Generally, implants of this magnitude are far too heavy for the human body to bear, but due to titanium’s lightweight and high strength, a patient-specific replacement could be 3D printed that weighed less than 250 grams. Thanks to the success of the 3D printed implant, the patient fully recovered and was able to return to a normal life without dependence on external machines to help him breathe.

In a trail of ankle bone replacement surgery using patient-specific 3D printed titanium talas bones, patients reported positive outcomes. The bone replacement meant patients did not need to have a full ankle joint replacement. Talus bones are very patient specific anatomical features requiring a uniquely designed 3D part based on the patient’s CT scan data.

There have been significant US FDA approvals for 3D printed titanium implants in 2023, mostly covering spinal implants.

- Restor3d receives approval in 2023 for the first all-metal (titanium) 3D printed patient-specific instrument in ankle arthroplasty.

- SurGenTec receives clearance in 2023 for its posterior 3D printed titanium sacroiliac joint fusion system, TiLink-P.

- FloSpine receives FDA approval in 2023 for a 3D printed implant used to support the spine called the Tri-Largo Cervical Interbody Cage System.

- Eminent Spine receives FDA approval in 2023 for its 3D Cervical Interbody Fusion System of 3D printed titanium configurations.

- ChoiceSpine receives FDA approval in 2023 for its Blackhawk Ti 3D Printed Cervical Spacer System in titanium.

- CoreLink receives FDA approval in 2023 for its Siber Ti Sacroiliac Joint Fusion System of porous, nano-surfaced, 3D printed titanium implants.

Cycling

Recently cycle maker Carbon Wasp detailed why it abandoned aluminum and carbon fiber and turned to 3D printed titanium for its newest aftermarket crank arm. “We came up with all sorts of creative ways to clamp the cranks on to the gearbox axle without pinching the carbon fiber but always needed to include some metal inserts … , but had no end of issues with bonding the insets to the carbon.” After some prototyping, Carbon Wasp found that 3D printed lattice-filled titanium cranks were as light as carbon but more robust in an area that is very exposed to impacts.”We still think carbon fiber is the best material for many other uses, including frames, … but we are already working on other titanium parts.”

Speaking of full frames, bicycle manufacturer Angel Cycle Works 3D prints a full titanium frame in one lightweight piece, which takes critical seconds of race times and enables new design geometry, the company says. Its new hyperbike, called Heaven, is 400g lighter than previous versions. Another full titanium frame is from Pilot launched this year called the Pilot Seiren. This road bike features a frame that’s entirely 3D printed (in three parts) from titanium. The company says 3D printed titanium enables it to custom fit bikes to riders’ preferences and the frames do not need any paint or coating.

“The printing process facilitates thinner wall thicknesses, leading to a lighter and stronger frame without stress points,” Pilot’s Tim Blankers told Road.cc cycling website. “The frame weight is just above a kilogram. Pilot can also add material in places where stiffness is desired to optimize power transmission.”

There are plenty of 3D printed titanium components on the market for cycling and a trove introduced in 2023:

- Silca revealed its newest line of 3D printed products earlier this year including a series of titanium derailleur hangers.

- Verve Cycling and Metron Additive Manufacturing launched it’s 3D printed titanium crank called the InfoCrank 3D Ti.

- Moots launched new 3D printed titanium drop-outs and accessories for its new Routt CRD gravel bike.

- Canyon announced a partnership with US sustainable 3D printing titanium specialist IperionX, suggesting the brand could release titanium 3D printed parts soon.

- Cane Creek launched new titanium 3D printed Electric Wings cranks that are as lightweight as a carbon crankset, but as durable as an aluminium one, the company says.

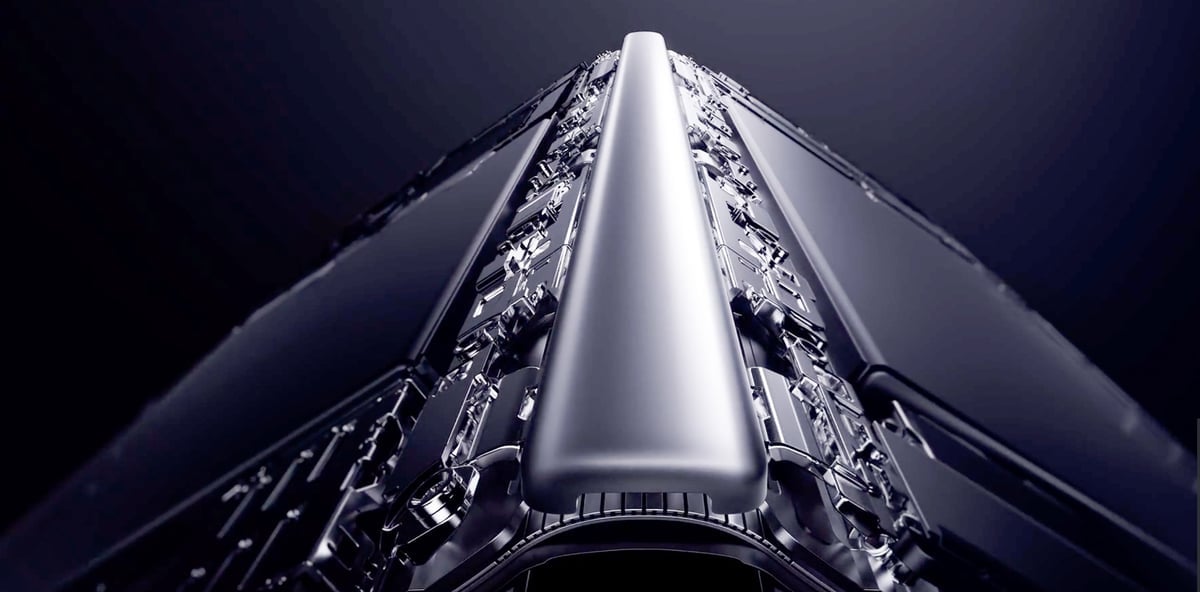

Aerospace

In the aerospace industry, several titanium-based additively manufactured parts are currently in commercial and military use, with numerous other prototypes making their way toward FAA certification. 3D printed titanium is prized for its low “buy-to-fly” ratio — an aerospace term that refers to the correlation between the weight of the initial material and the printed part’s weight.

Several contract manufacturers specializing in the aerospace, defense, and space markets, such as Primus Aerospace, StarHagen Aerospace, and Zeda, have invested in 3D printers capable of producing titanium components for both prototyping and final parts.

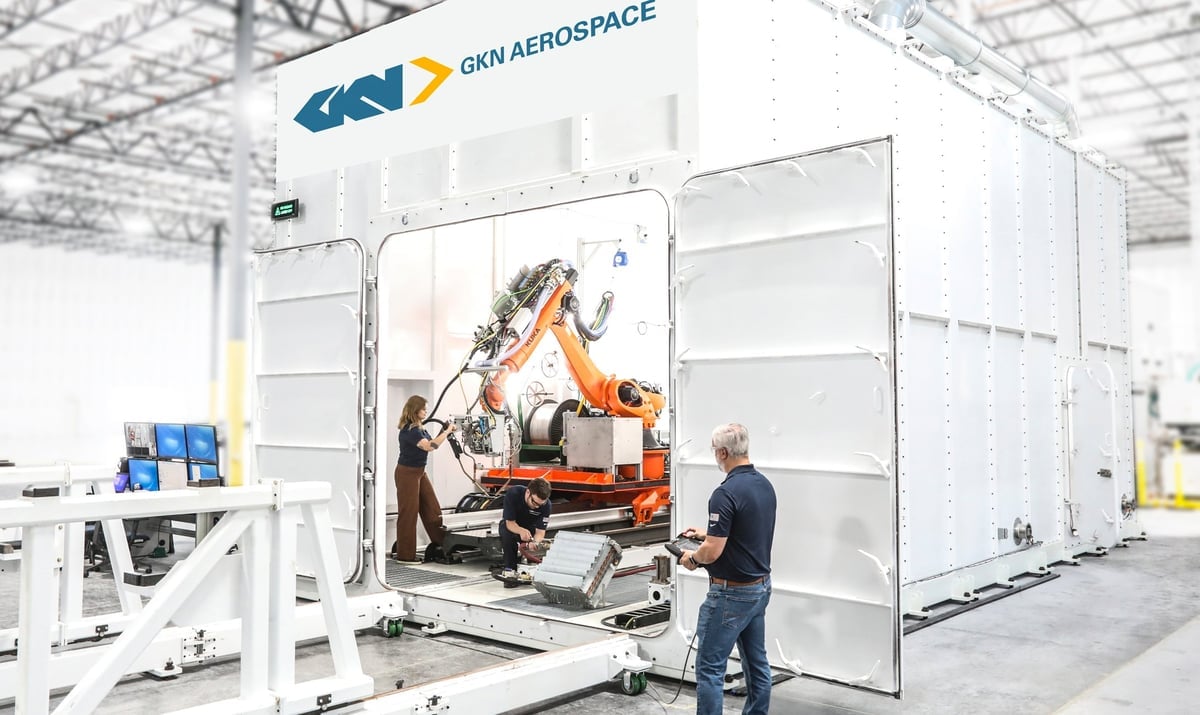

In 2023, GKN Aerospace announced it was planning to build a huge 3D printing cell as part of its new Global Technology Center in Texas, which will 3D print titanium aircraft structures. Called the Cell 3, the printer can make five-meter long titanium components.

Manufacturing

Turning to 3D printed titanium for a completely different reason, semiconductor manufacturer ASML now has its titanium carrier tray preforms (used for wafer production) 3D printed instead of forged, which saves 64% in raw materials and is delivered faster. Norsk Titanium, a metal additive manufacturing company used directed energy deposition (DED) platform, Norsk is printing 80-kilogram (about 176 pounds) near-net-shape preforms — used for semiconductor wafer production — out of Ti64.

Norsk worked with Dutch partner Hittech Group to develop the preform, which, according to Norsk, is used in ASML’s lithography system. ASML, also based in the Netherlands, has been one of the world’s most frequently discussed companies in the context of the chip shortages over the last few years. Specifically, ASML is most well-known for producing the world’s only extreme ultraviolet (EUV) photolithography machines.

Even the US Navy is turning to 3D printed titanium to save time and money and eliminate dependence on a foreign supply chain. Having no domestic capacity to manufacture the large titanium castings required for high-performance centrifugal pumps, the Navy is plagued with long lead times and a supply chain that exploits high-cost and carbon-intensive titanium raw materials. But soon, with new domestic partners IperionX for recycled titanium powders and Carver Pump for additive manufacturing, the Navy will gain the capability to significantly reduce lead times for critical parts, increase equipment availability, and sustainably re-shore a critical US titanium metal supply chain.

Know Your Titanium

Pure titanium is not typically used in engineering applications while it is common in the biomedical market for parts, such as knee and hip implants. Titanium-based alloys – controlled mixes of metal constituents that provide specific mechanical properties – are used in a wide range of industries that need to achieve very specific part properties. Metal material suppliers, who have long supplied manufacturers with titanium for casting, are now offering titanium powders formulated specifically for additive manufacturing.

Titanium filament for extruder-based fused deposition modeling (FDM) is available from a few companies, including Virtual Foundry. This material contains metal powder embedded in PLA and can be printed using FDM printers with extruder temperatures above 205 °C. Once post-processed and sintered, these filaments can produce metal parts that are more than 90% metal, making them suitable for prototypes. If you’re looking for metal filament, watch out for the ones called titanium referring only to their gray color.

Titaniums for Additive Manufacturing

- Titanium 6Al-4V, grade 5 is the most commonly used in titanium alloy in additive manufacturing and it is ideal for prototypes and functional parts in the aerospace and automotive fields and for military applications. It is also an excellent material for the manufacture of parts with complex geometries and precisions, and production tooling.

- Titanium 6Al-4V, grade 23 is a biocompatible alloy commonly used for medical implants and prostheses.

- Titanium Beta 21S exhibits a higher strength than conventional titanium alloys such as Ti-6Al-4V and has superior oxidation resistance and creep resistance compared to conventional titanium alloys such as Ti-15V-3Cr. Grade 21 Titanium has one of the lowest hydrogen uptake efficiency levels of any titanium alloy. It is an ideal candidate for orthopedic implants and aerospace engine applications. Beta titanium is widely use in orthodontics.

- Cp-Ti (Pure Titanium), grade 1, 2 are extensively used in the medical field for a wide range of applications due to the biocompatibility of titanium with the human body.

- TA15 is a near-alpha titanium-alloy with additives of aluminum and zirconium. The high specific strength of components made of TA15 combined with their high load-bearing capacity and temperature resistance enable them to be used for heavy-duty components in aircraft and engine construction.

Titanium Suppliers

There’s a wide range of titanium and titanium alloys specially formulated for 3D printing in a range of particle sizes and purities from material manufacturers, including:

- Carpenter Technology: TI 6AL-4V ELI

- Heraeus: Ti6Al4V Gr.5 and Gr.23

- Sandvik: Osprey TI-6AL-4V Gr.5 and Gr.23

- GKN: CPTi – Gr.1 and Gr.2, Ti64 – Gr. 5 and Gr. 23, Ti6242, Ti5553, Beta 21S

- AP&C (a GE Additive company): CPTi – Gr.1 and Gr.2, Ti-6AI-4V Gr.5 and Gr.23, Ti-6Al-2Sn-4Zr-2Mo, Ti-5Al-5V-5Mo-3Cr

- AstroAlloys: TruForm Ti-6Al-4V Gr.5 and Gr.23, Ti-48Al-2Nb-2Cr, Ti-6Al-2Sn-4Zr-2Mo

- Uniformity Labs: Ti64 Gr.23

- Tekna: Ti64

- PyroGenesis Additive: CPTi – Gr.1, Ti-6AI-4V Gr.5 and Gr.23

- IperionX: recycled Ti

How to 3D Print Titanium

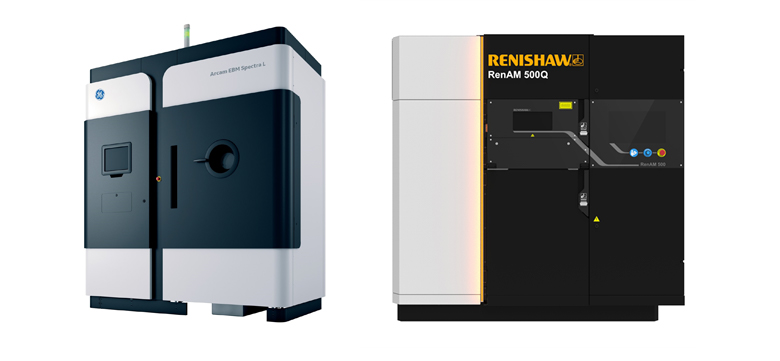

There are several metal 3D printing technologies for processing titanium-based alloys, but powder bed fusion processes – laser powder bed fusion, electron beam powder bed fusion – using powdered titanium are the most commonly utilized.

“The majority of titanium AM parts are built with powder bed technologies,” according to a report by the consultancy Ampower. “While powder bed fusion is used to produce light-weight components for aviation and racing as well as medical implants, binder jetting is typically used to produce smaller medical instruments from titanium.”

Laser powder bed fusion (LPBF), also called selective laser melting (SLM), is a manufacturing technology that uses powdered metal used by a high-power laser. LPBF produces a part by adding a layer of material to a previous one. Based on the properties of the titanium-based alloy to be processed, the LPBF processing parameters must be optimized and tuned to control porosity, microstructure, and final material properties.

Electron beam powder bed fusion (EB PBF), also called electron beam melting (EBM), is a similar process but uses a higher-power electron beam instead of a laser. The high process temperature of the electron beam results in slower cooling of the single layers and therefore coarser microstructure compared to LPBF, according to Ampower.

In the powder bed fusion processes, the metal 3D printers start to work from a metal powdered bed, which is selectively scanned. All the geometrical information is given to the printing system from a CAD model previously defined in a 3D modeling software. The powdered material is mainly characterized by features like particle morphology (irregular or spherical) and particle size distribution. Spherical morphology is desired to allow a good flowability of the powder once the printing process is ongoing. The process from which the powder is created determines its final features. Metal powders can be manufactured by gas atomization, rotary atomization, plasma rotating electrode process, and water atomization. The bottom line is that quality powder will produce quality parts.

Other additive manufacturing methods suitable for titanium include direct energy deposition (DED), rapid plasma deposition (RPD), and binder jetting.

Titanium 3D Printers

The current market of 3D printing systems offers a wide variety of metal 3D printers for processing different titanium-based alloys.

Powder Bed Fusion (PBF)

- 3D Systems offers three types of titanium material compatible with several of its PBF 3D printers.

- EOS offers five titanium material options that work on its four metal powder bed fusion 3D printers.

- GE Additive offers titanium and titanium alloys for its Concept Laser line of SLM 3D printers.

- SLM Solutions provides three titanium alloys for its range of selective laser melting 3D printers.

- Velo3D has a titanium solution for its PBF 3D printers.

- Trumpf’s laser metal fusion 3D printer is designed for titanium part production.

- Renishaw metal 3D printers are popular for producing titanium parts in the medical and dental fields.

- AddUp’s FormUp350 laser metal fusion 3D printer is compatible with titanium.

Binder Jetting

- Digital Metal offers one titanium alloy on its binder jetting 3D printer.

- Desktop Metal offers titanium on its Studio, X-Series and Production System printers.

Electron Beam Melting (EBM)

- GE Additive offers titanium and titanium alloys for its EBM 3D printers.

Cold Fusion

- Spee3D announced in 2022 that it now has the capability to 3D print with titanium.

Fused Deposition Modeling (FDM) & Extrusion

- Desktop Metal offers a proprietary filament filled with titanium alloy for three printers using its extrusion Bound Metal Deposition technology.

- Meld Manufacturing is a unique solid-state technology specializing in larger parts.

Properties of 3D Printed Titanium

An essential concern in both powder-bed processes is how the material microstructure evolves during printing, and how both the energy density and the transferred heat interact with material crystal lattices. This interaction is reflected in the time-dependent temperature profiles that the laser beam or electron beam transfers to the feedstock.

3D printing subjects the titanium to multifaceted and complex thermal processing cycles that affect the mechanical properties of the material. Establishing trends and relationships between them is difficult because every printer is different, materials vary, and there’s a range of perimeters to fine-tune. There’s been a lot of research in this area lately, and most point to the exceptional structural integrity of 3D printed titanium parts.

In March 2021, metal 3D printer manufacturer MELD Manufacturing released data confirming that its process produces titanium meeting the ASTM and AMS standard requirements for forged material, as printed.

The data was generated through a program with the National Center for Manufacturing Sciences (NCMS), Army Research Laboratory (ARL), and the Advanced Manufacturing, Materials, and Processes (AMMP) program using Ti-6Al-4V (Ti64) material, also known as ASTM grade 5, for the testing.

The data highlights that the as-printed material exceeds the minimum requirements for yield strength, ultimate tensile strength, and elongation as specified in ASTM standards in all axes, including in the Z direction through the print layers.

The number of US FDA-approved titanium-based 3D printed surgical implants continues to grow as medical manufacturers increasingly adopt additive manufacturing in their production capabilities.

Order Titanium Parts

If purchasing your own metal printer for titanium parts isn’t feasible, a wide range of third-party 3D printing services offer the material and some offer design services. Be sure to inquire which alloy they offer, because pure titanium may need to be specially ordered.

At the online 3D printing marketplace, Craftcloud by All3DP, you can upload your digital file, select titanium, and receive quotes from third-party 3D printing services. Several printer manufacturers, including Stratasys, 3D Systems, and EOS, plus material manufacturers, such as Sandvik, offer titanium print-on-demand services.

Custom Titanium Implants & Surgical Guides

As 3D printed titanium rapidly gains regulatory approval for custom implants, traditional medical device manufacturers and specialized 3D printing start-ups, including Zenith Tecnica, 4Web Medical, Camber Spine, Amnovis, and Nexxt Spine, are increasingly offering the service.

Recently, the ProMade PoC Center for Complex Orthopedic Solutions made news as the first point-of-care center for complex cases operated by a medical device company on hospital grounds. LimaCorporate, an Italian company specializing in the design and 3D printing of complex orthopedic solutions, partnered with New York’s Hospital for Special Surgery (HSS) to bring clinical care and bio-mechanical engineering expertise to one location.

Lead image source: 3D printed titanium aircraft parts from Zenith Tecnica

License: The text of "Titanium 3D Printing – The Ultimate Guide" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.