When you 3D print with FDM filament in (or as) your business, you can’t have poor layer adhesion or material inconsistency. Your parts can’t unexpectedly break, warp, melt, or delaminate. Plus, wasting time and raw materials fine-tuning printer settings over and over again is out of the question.

In this guide, we walk you through how to choose and use a professional FDM filament that will meet the mechanical and aesthetic specifications of the parts you need to print. You’ll learn how to read a filament specification sheet and why all of those measurements matter.

Ever Expanding Universe of FDM Filament Types

Filament is like cookies; there are thousands of different kinds, and even those that claim to be chocolate-chip can differ dramatically.

Take polycarbonate (PC) for example. “What one company might sell as polycarbonate may have a lot more additives than another company’s, affecting not only how it should be printed, but also many of the properties of the end print,” explains Justin Cockrell, founder of the Arkansas-based 3D printing service Hudson Creative Group, which prints more than 1,000 parts a month for customers.

In fact, a neat or pure polymer isn’t even what you’d want in a 3D printing filament. “There always needs to be several other ingredients in a polymer recipe, such as stabilization packages or processing agents,” says Sylvia Monsheimer, head of new 3D printing technologies at Evonik High Performance Polymers. “They’re usually only present in a very low percentage, but they are absolutely necessary and make a decisive difference in processing and part performance later on.”

So if every professional FDM filament on the market is different, how do you pick the best ones?

Trust Your Printer Manufacturer

When each FDM filament prints differently, each one will have its own sweet spot when it comes to extruder temperature, build plate temperature, cooling time, print speed, and other variables. These variables can be slightly – or dramatically – different depending on your printer brand. Changing any of the variables, costs time in terms of testing the combination, altering settings, and re-printing before finding acceptable results.

This process can waste a ton of material, too. In fact, you can expect to print 1 to 2 kilos of filament developing your own print profile to get to the point where it’s a one-click operation.

“Ease of use and repeatability are the driving factors for professionals,” notes Douglas Krone, CEO of printer and materials supplier Dynamism. “Professionals are driven by time-savings, so they prefer tested combinations of hardware, filament, and slicer settings.”

These tested combinations come from your printer manufacturer and sometimes from your filament manufacturer.

For example, Ultimaker recommends using its own Ultimaker brand of FDM filament because it’s been exhaustively tested on their machines (they test other filaments, too). They publish their optimized printer settings and official material profiles to give you excellent out-of-the-box results. They’ll even tell you when a filament is “experimental” or is “not recommended”, as in, don’t waste your time.

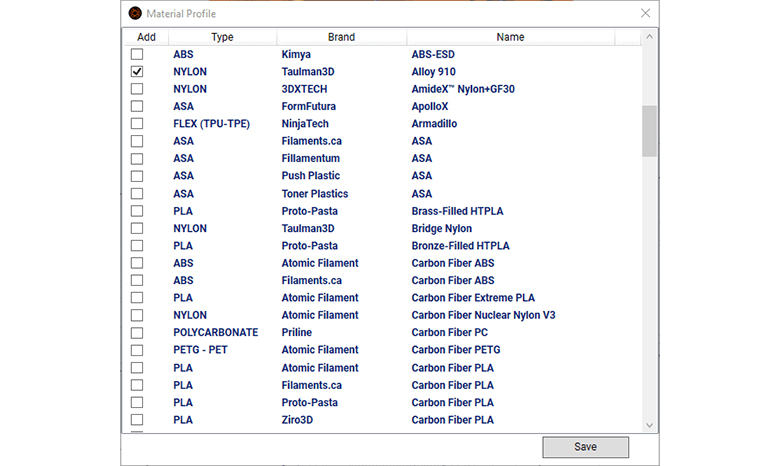

These profiles of Ultimaker materials and other filament brands are all uploadable to the latest version of Ultimaker Cura slicer software.

Even printer manufacturers that boast an open filament platform have spent hundreds of hours testing major FDM filament brands on their machines to offer you the ideal settings for whichever filament you want to use.

For example, Raise3D collaborates with major filament manufacturers to identify and select top-performing filaments for its printers, and then provides the optimal printing profiles. Raise3D’s website lists more than a hundred profiles you can upload into your Raise3D ideaMaker slicer software.

In fact, most professional FDM printers offer material profiles. If your’s doesn’t, you’re not completely out of luck. Often, there are user forums online, such as at Thingiverse, where you can find and share consumer-created printer profiles for a wide range of materials.

High Print Speed, Low Part Strength

Are the printer setting you select more important than the filament you select when it comes to the properties of your final part? This is a question the industry hasn’t fully answered yet, but you probably already know that settings make a huge difference.

For example, some research (“Process–Structure–Properties in Polymer Additive Manufacturing via Material Extrusion: A Review“) has shown that final part tensile strength drops as the feed rate increases. Although this may not be the case with all filament, it’s an example of how your printer settings affect the properties of your final part.

The more options your printer has for precisely controlling variables, such as print speed, and bed, chamber, and nozzle temperature, the more reliable your prints will be.

In the end, it’s another reason to follow the research-based guidance of your printer manufacturer.

When in Doubt, Tough PLA

“Overall, Tough PLA is the most commonly used material for professional users,” says Krone at Dynamism. “It has a great combination of strength, durability, and ease of use.”

Tough PLA, which comes in a wide range of formulations, is also tops for pros at MatterHackers, the US-based 3D printing material manufacturer and supplier. “Tough PLA is a super useful upgrade to standard PLA for professionals because it provides quite a bit more toughness with no additional printing complexity,” says Dave Gaylord, MatterHackers’ vice president of product and technology. “PLA is used for every first prototype and can successfully achieve form and fit goals for any design. It’s not until functionality becomes part of the picture that next level materials are used.”

When it comes to functional parts, professionals also head towards nylon (PA) and other nylon specific materials, says Gaylord, some with additives for strength and stiffness. “PETG is also used widely for snap-fit and functional parts,” he says.

At Hudson Creative Group, Cockrell says his customers find PETG the best “all around” filament for printing most functional models. “It’s the best of both worlds between PLA and ABS, with more overall strength and heat durability than PLA, but without the shrinkage and poor layer adhesion commonly associated with ABS,” he says.

Flexible or rubbery filament (or elastomers) are used widely in manufacturing and automotive when there’s a need for custom replacement gaskets or robotic grips. Material manufacturer Fillamentum sells more of these types of materials to professionals than anything else, says company CEO Josef Dolecek. “We sell a wide range of different types of elastomers – TPU (thermoplastic polyurethane) and high-performance elastomers like PEBA –because they are excellent cost-effective alternatives in manufacturing and have resistance to fuel, oil, and solvents.”

Know Your Tech Specs

Few enjoy reading through “percentages of elongation at break” or “joules per square meter of impact strength” on filament spec sheets, but if you need to experiment with FDM filaments when no print profile for your machine currently exists, this is the place to start.

“Technical resources are huge when you’re looking to expand into new materials and out of your comfort zone,” says Gaylord. This means, among other things, knowing how to read a material technical data sheet (TDS).

Unfortunately, there’s no standard format for filament tech spec sheets. There are different terms for the same thing, different international testing methods (ISO, ASTM, etc.), different units of measurement, different results cited (maximum, average, etc.), and a range of other variations that make direct spec sheet comparisons difficult.

Complicating matters even further is the fact that some filaments don’t even mention a polymer family, such as PLA or PC or TPU, as a base, they are simply named “flex”, “tough”, “smooth”, or “durable.”

However, as long as you understand the following concepts and how they relate to the characteristics you need in your final print, you’ll be able to glean the necessary information. It should go without saying that if a filament doesn’t come with a spec sheet, walk away.

Strength

Of course, you want your parts to be strong, but what exactly does that mean? There is a wide range of scientific measurements around strength. You’ll typically find at least three on your filament spec sheets.

- Tensile strength (also known as ultimate tensile strength, tensile strength at break, ultimate strength, Ftu) refers to tension or stress a material can take while being pulled apart before breaking. Testing tensile strength involves literally putting the material in a vice-like machine and pulling it in opposite directions. In practical terms, this measurement relates to how quickly your part will break or its brittleness. For reference, stainless steel has a tensile strength of 860 MPa; glass is 33 MPa.

- Flexural strength (also known as yield strength, modulus of rupture, or bend strength) refers to how far a material can flex or bend without breaking. Don’t confuse this with flexural modulus, which is how much a material will resist bending. Wood (pine), for example, has a flexural strength of 41.4 MPa, while ABS is 60 MPa.

- Impact (also known as Izod or Charpy impact strength or, generally, as toughness) is how your part will shatter if you drop it or how it will resist breaking when force is applied. You’ll see these force measurements in either joules per square meter (J/m2) or foot-pound per square inch (ft·lb/in2). A 40% glass-fiber-filled polycarbonate, for example, could have a low-impact strength of 110 J/m2, while a “high-impact” ABS could have about 500 J/m2.

Flexibility

If you need your final parts to have a degree of flexibility you’ll want to pay attention to a few key measurements.

- Flexural modus, as mentioned above, is the tendency for a material to resist bending, in other words, its stiffness. A high flexural modus means the material is not very flexible. Most carbon-fiber reinforced PA 12s, for example, are pretty stiff and have a max flexural modus of around 14 Gpa. Flexible PA 11s, on the other hand, will have a flexural modus of 0.65. Note that you’ll see flexural modus presented in either megapascals (MPa) or gigapascals (GPa, which is MPa times 1,000).

- Elasticity (also known as Young’s modulus, tensile modulus, compressive modulus, or elastic modulus) evaluates the elasticity of a material, which is a ratio between the deformation of a material and the power needed to deform it. Typical TPU filament, for example, has a tensile modulus of around 70 MPa (very elastic), while most PEEK filament has a tensile modulus of 3720 MPa (not elastic).

- Hardness can seem like a vague term when it comes to polymer filaments. It can refer to scratch resistance, wear and abrasion resistance, or the part’s ability to be dented. Hardness of plastics is often shown as a Rockwell or Shore value, which can have little to do with a material’s strength or flexibility. Shore hardness is a common term you’ll hear when it comes to polymers, but it’s more general than the measurements above. For example, all elastomers and flexible filament, such as TPU, would be Shore A, and within the A category, they would have individual values, such as Shore Hardness 95A.

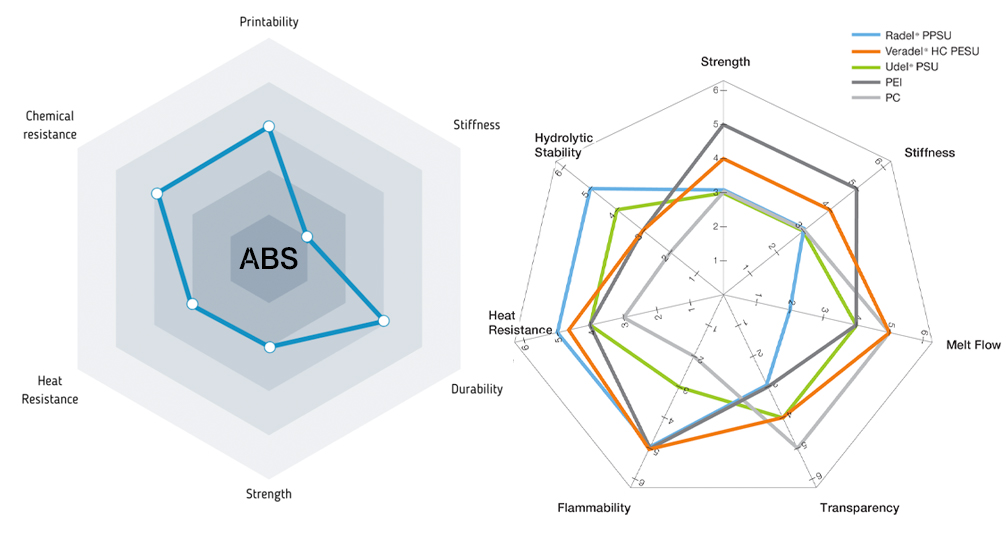

To make deciphering these terms and measurements a little more user-friendly, several material manufacturers have begun using spiderweb-looking charts of key attributes to give you an at-a-glance summary. These are useful snapshots of a filament’s major characteristics in relation to each other, however, no two manufacturers select the same six or seven filament properties or display them in the same order, so they’re not very useful for comparing professional FDM filaments.

Other useful information found on many, but not all tech data sheets, include the humidity or water absorption value (.01 is low, 3 is high), which could be important in determining how you store and how long you dry your filament; and glass transition temperature (Tg), which is not the melting temperature but rather indicates the maximum temperature under which a part will maintain its structural integrity. In other words, don’t go over the Tg when printing or subject your final parts to temps over that level.

Of course, with these terms, we’re just scratching the surface of what you can find on a professional FDM filament technical data sheet, but they are the most common.

Database of Spec Sheets

Fortunately, you don’t have to visit each manufacturer’s website and download all of their filament spec sheets; you can search a few popular material databases.

The Material Data Center (by the M-Base Engineering + Software company) offers a free material data sheet lookup function with thousands of brands of polymers. They’re not all filaments, so make sure you’re not looking at a product for induction molding. The somewhat quirky but generally reliable Senvol Material Database features the ability to search polymer material tech sheets by the mechanical feature you require. For example, you can enter that you want a PLA with a minimum tensile strength of 40 Mpa, a minimum flexural modulus of 10 MPa, and a glass transition temperature of 140 ºC. The result page will list all the filaments and each filament data page will also list the know compatible 3D printers, pretty handy.

Not quite as user-friendly but comprehensive is the Campus database of polymer materials, which is a good resource for industrial materials.

Stick With Brands & Suppliers You Trust

Amazon sells great quality filament, but they won’t answer the phone when you have questions. Building relationships with material suppliers or brands who value that relationship is the pro approach.

“Ensure that the materials you chose are provided by a company who has your back and knows how to speak technically to your applications and material property needs,” says Gaylord.

Quality material manufacturers and suppliers have engineers on staff who spend a lot of time testing materials and updating technical data sheets. Several offer regular webinars on printing and FDM filament choice, and may even test a filament on your brand of printer and develop a custom profile for you, saving a lot of time and effort.

Suppliers and manufacturers are also the ones who have tested countless designs with various filaments. Your part design, including wall thickness and infill, also effects which filament is best for the job. You’ll find that properties, such as toughness and tensile strength, also depend on the intricacies of your part design.

Take Storage Requirements Seriously

How and where you store your yet-to-be-used filament for your business can have a big impact on your final parts. Environmental factors, such as exposure to oxygen, temperature, and humidity are known to affect final part quality and a part’s mechanical properties.

Research has shown that filament exposure to oxygen, moisture, and heat while in storage affects the print quality and mechanical properties of the final part, in some cases robbing the final print of nearly 20% of its tensile strength.

Filament is best kept dry in vacuum bags, a dry box or cabinet or a specialized 3D filament box. The printer material profiles often also include the length of time you should dry your filament before using it and at exactly what temperature.

Custom Made Industrial Filament

You could spend a lot of time driving from store to store trying on suits from dozens of different brands, or you could head to a tailor and have one made. Shopping for filament can be the same experience. But like hiring a tailor, it comes at a price, and not everyone needs it.

Industrial enterprises in aerospace, oil & gas, and medical manufacturing are turning to specialty polymer manufacturers, such as Evonik, Solvay, and Arkema, to develop high-performance polymer filaments that match the part performance they require for their custom end-use parts.

“We design polymers to have the best processing windows specifically for additive manufacturing, which is different than other types of manufacturing,” says Brian Alexander, global product and business development manager at Solvay Specialty Polymers. In fact, many of Solvay’s customers are already using polymers in injection molding, and are looking to transition to additive manufacturing for all of the benefits and efficiencies it offers, but need a different recipe for their polymer.

For these industrial manufacturing customers, the polymer comes before the printer. “If you don’t have the right machine you’re very limited in what you can do,” notes Alexander. In designing a polymer for additive manufacturing, Solvay and other specialty polymer companies, consider the end use and design of the final part and what mechanical properties it needs, then find a specialty polymer that can meet these requirements and use the polymer’s digital twin to simulate the best part design and processing conditions, including everything from filament drying time and temperature to post-processing.

“The ultimate goal is to get the trial and error out of the process before you start printing,” says Alexander.

Lead image source: FormFutura ReForm rPET is a recycled PETG

License: The text of "Engineering-Grade 3D Printer Filament – All You Need to Know" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.