Ah, that sweet smell of melting plastic is a reassuring sign that your 3D printer is hard at work. But you’ve likely wondered: How harmful are those 3D printer fumes? Should I have my 3D printer running overnight in my bedroom or should my office workers be sitting in the same room as my printers?

Here, we take a look at the latest science, studies, and best practices for maintaining safe air quality wherever you house your printers.

What exactly is that smell?

Research has shown that all 3D printers produce various emissions while they work. Some of them are harmless off-smells from heated materials, but others have been linked to health risks. “Potential health and safety hazards vary widely depending on the technology and materials used, as well as where the printers are located and any controls that may be in place,” according to a 2023 report and guide from the US Centers for Disease Control (CDC).

Of particular concern are the particulate matter (PM) and volatile organic compounds (VOCs) wafting from your printer – and here we’re referring to both filament-based and resin-based 3D printers.

When inhaled, ultrafine particulate matter can build up in your lungs, which can cause respiratory illnesses such as asthma. Particulate matter may also be absorbed into the circulatory system and be transported into other organs. This is true for 3D printing fumes just like it is for particulate matter from car exhaust, wildfires, and hundreds of other sources of airborne pollution. But, although there may not be much you can do about your town’s air quality, there are steps you can take to reduce the harmful effects of your 3D printing.

Why should you be concerned about breathing in 3D printing fumes? Certain VOCs from 3D printing have been found to be carcinogenic – in other words, they could potentially cause cancer. Although the toxicity of all these emissions isn’t yet perfectly understood, and research is ongoing, all 3D printer users should be cautious about their printer’s emissions.

The topic is getting more attention.

So far in 2024 alone, we found newly published reports on FDM filament emissions and human health.

In this article, we review all of the latest research to find out which materials and printing methods produce the most harmful emissions and how you can best protect your office or home from them.

Dos & Don'ts of 3D Printing & Air Quality

Before we dive into the large amounts of data we’ve gathered on 3D printers and the impact their emissions can have on health and air quality, let’s cut to the chase and give you the best practices upfront.

Do …

- place 3D printers in well-ventilated locations

- use a 3D printer enclosure with a HEPA filter for FDM and resin printers

- use lower emissions materials, like PLA filaments

- use materials from reputable manufacturers

- use the lowest possible printing temperature that provides successful prints

- regularly monitor air quality in the printing area with an appropriate sensor

- keep your printing environment free of dust and other airborne pollutants

Don’t …

- rely on only one emission-mitigation method, use several

- trust that a large printing room alone will mitigate emissions

- operate 3D printers around children without air quality mitigation (filters, ventilation, etc.)

- operate 3D printers without enclosures and air quality mitigation in an office environment

- buy cheap filament that may be of suspicious quality

Safety Standards for 3D Printing Environments

There had always been a lack of “official” guidance when it comes to 3D printer fumes until the folks at Chemical Insights, a research institute of Underwriters Laboratories (UL), the global safety science company that specializes in product safety testing and standards development, issued a comprehensive guide on 3D printing safety in 2023.

Developed with the Campus Safety, Health, and Environmental Management Association (CSHEMA), the guide targets the use of 3D printing at universities and within student labs and housing, but it’s applicable to anyone looking to buy a printer and print safely. In fact, “UL 200B: Guidance Document for Safe Use of 3D Printing for Institutions of Higher Education” covers virtually all of the best practices for safety, and many you may never have thought of.

Because there are no regulated standards for acceptable indoor air pollutant levels in non-industrial environments, such as homes, offices, and schools, the guide is a great reference detailing the recommended exposure limits and odor thresholds for common air pollutants in environments.

“The first choice for the location of 3D printing activities should be in spaces with dedicated ventilation,” the guide notes, since 3D printers have been shown to emit ultrafine particles (UFPs) and a complex mixture of organic volatile compounds (VOCs) when operating.

If dedicated ventilation is not available, the second option is to exhaust the air from printers through a room air cleaner equipped with HEPA filtration for particles and activated carbon filters for VOCs or to purchase a benchtop, single-unit fume extraction system to be used while the printer operates.

Emissions from FDM Printers

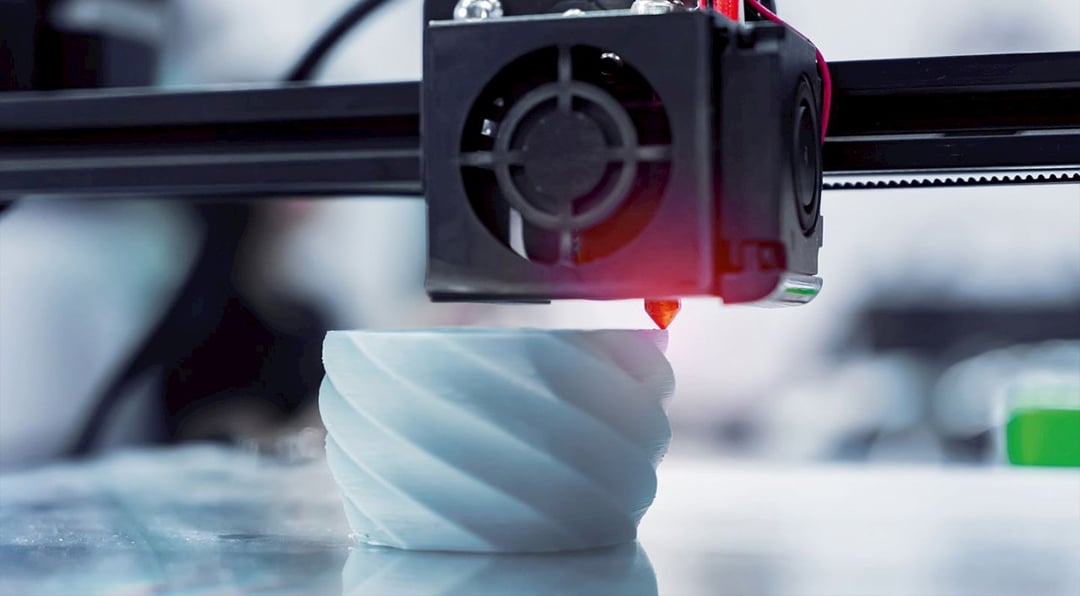

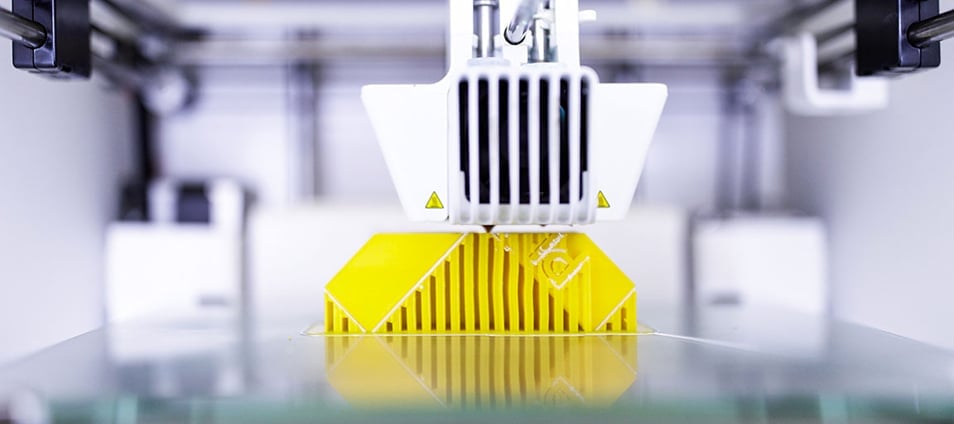

Fused deposition modeling printers (those that use spools of filament) are the most common types of 3D printers on the market, particularly at home, but they’re also popular commercially. It’s no surprise, then, that their emissions have been studied most closely.

FDM printers function by melting plastic filament. Heating plastic causes minor decomposition in the filament. Even though it doesn’t impact print quality, it is enough to produce particulate matter in the ultrafine range. Similarly, VOCs are formed when chemicals in the filament degrade during heating.

However, as the printing process goes on, VOC emissions generally fall to low levels after around five minutes. The highest peak of emissions is detected immediately at the beginning of the printing process for both particulate matter and VOCs. Ironically, the reason for the decrease in VOC lies in the ongoing particulate matter emissions. VOCs bind readily to particles, which helps drive down VOC levels.

All FDM printers release both ultrafine particulate matter and VOCs that could be harmful to human health, studies show. Let’s explore that “could be” statement a little bit more. Naturally, no one has locked a group of people into a sealed room with 3D printers running for an extended amount of time and measured the health effects. Most studies have been done on the emissions and how the chemicals in those emissions have shown to affect health from other studies, such as on air pollution. These are extrapolations that if these chemicals from pollution are harmful then the same or similar chemicals from 3D printers are also likely harmful. Other studies have exposed human cells or animals to 3D printer fumes.

One 2024 study investigated the health effects of emissions from two common 3D printing filament types, ABS and PLA, on human lung cells. Both types of emissions increased levels of certain inflammatory markers in the cells, which could contribute to lung diseases like pulmonary fibrosis and COPD.

Another 2024 lab experiment exposed rats to 3D printer emissions of polycarbonate (PC) filament. The unfortunate rodents breathed PC fumes four hours a day, four days a week, for a month, yet, fortunately, showed “no marked pulmonary or systemic toxicity.” Researchers noted, however, that their findings were inconsistent with toxicological results observed in studies using cell specimens, and further study is warranted.

Researchers have found that not all FDM printers produce the same level of harmful emissions, and other, various factors can impact emission levels, such as filament material, print temperature, nozzle diameter, and extrusion rate.

Several studies, such as one by the US Environmental Protection Agency (EPA), have found that filament type can have a large effect on emissions. This is due to additives and contaminants present in filament. Manufacturers use different methods, additives, and coloring agents in their filaments, which naturally leads to varying emissions profiles.

The FDA found: “As the popularity of 3D printing grows, and applications spread from industry to the household, there is a critical need to investigate filament additives to assess their health risks. Future work will investigate other additives (dyes, metals) and involve characterization of both VOCs and particulate matter.”

One FDA study found that carbon filled ABS emitted more gasses than regular ABS, which could “potentially pose an inhalation hazard to users printing several kilograms of material.”

Researcher Rodney Weber of Georgia Institute of Technology, who conducted experiments on filament emissions in 2017 recommends against buying the cheapest filament on the internet and, instead, following your printer’s filament recommendations. “What we found was the filaments that were cheaper or we didn’t buy them from the printer manufacturer, could have much higher concentrations of aerosols emitted than filament from more of a reputable manufacturer,” he said.

Another contributing factor to FDM emissions is printer brand. One study notes that machines from different manufacturers heat material at different rates and temperatures, which impacts emissions. Curiously, printer brand is a larger factor when printing with PLA and Nylon filaments, while with ABS filament and printer brand are roughly equally significant. Unfortunately, most studies did not actually name which brands of printers they investigated. One 2016 study did compare MakerBot, Flashforge, LulzBot, and Dremel, but most of these printers have since been redesigned, so the findings may no longer be valid.

Pre-existing room air particles have an effect on 3D printer emissions, studies found. When your work area is dusty or full of airborne contaminants, like pet dander, these particles provided enough surfaces for vapors to condense on. This doesn’t lead to more emissions in the air, but instead larger particles, or particulate matter.

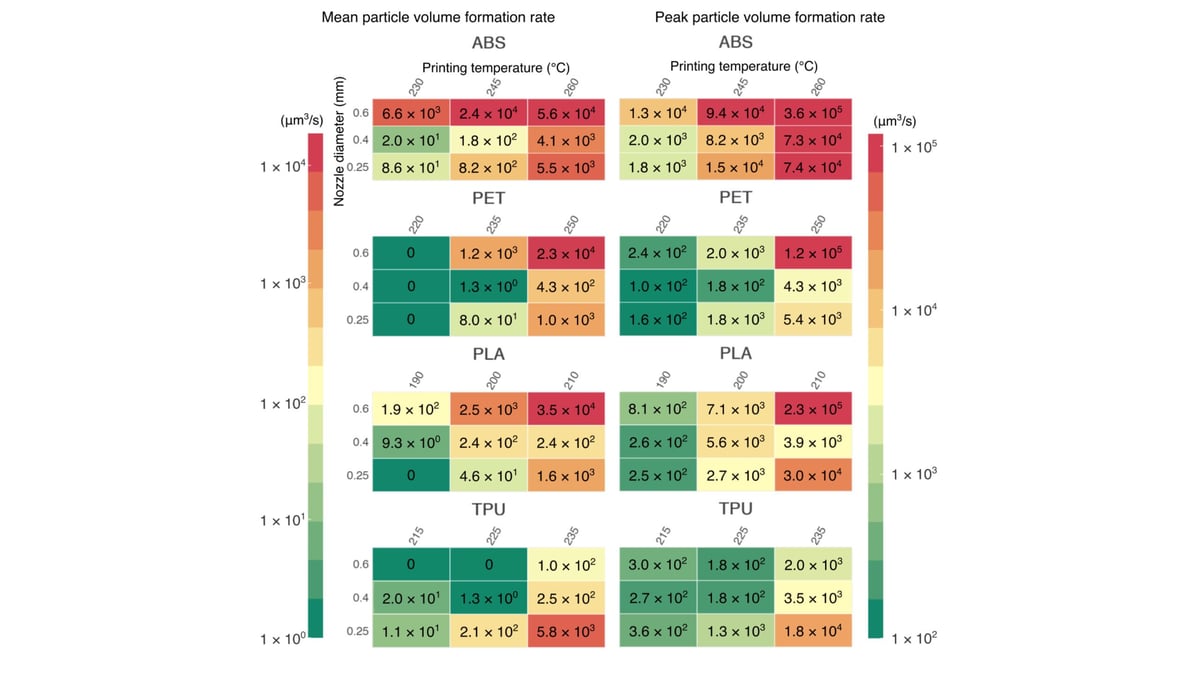

Lastly, a recent study found that nozzle size has an effect on filament emissions. According to a study in the International Journal of Environmental Research and Public Health: “Each of the filament materials tested have optimal extruder settings for which maximum concentrations of fine particle emissions can be significantly reduced. For ABS, PLA, and PET, the 0.4 mm nozzle was optimal. For TPU, the larger the nozzle diameter, the lower the emissions.”

Which FDM Materials Produce the Most Emissions?

The most important emissions factor in FDM printing is the type of filament used. There are no detailed studies comparing a wide range of types and brands. Most studies have concentrated on the three most common FDM printing materials – ABS, PLA, and Nylon.

In general, ABS is characterized as a high-emissions material. On top of the initial emissions burst of PM and VOCs, ABS produces a steady level of emissions throughout the printing process. However, as noted earlier, the ongoing emissions are mostly PM due to VOCs quickly binding to the emitted particles.

PLA and Nylon, on the other hand, produce lower levels of emissions than ABS. These materials create the same initial burst, but they do not produce ongoing emissions. As a result, some researchers call them low-emissions materials. However, they also note that emissions from PLA can very wildly based on filament brand, with some reaching levels comparable to ABS.

Just because PLA is made from biodegradable material like cornstarch, potato starch, and sugarcane, doesn’t mean breathing in its emissions is like walking through a farm field. Particles and compounds emitted from PLA are actually more toxic than those from ABS, according to a 2017 study from the American Association for Aerosol Research. But since PLA only produces them at high levels at the beginning of printing, ABS filaments overtake PLA in toxicity over time.

The exact toxicity of FDM printer material emissions is currently unknown. Although many of the emitted compounds are undeniably harmful, there have been no consistent studies on their toxicity impact, partially due to varying testing protocols and environments among researchers. Additionally, some less common materials, like TPU or PET, haven’t been accurately studied at all, leaving the data incomplete.

As a result, EPA and other researchers are calling for standardized testing to create reliable emissions standards for 3D printers.

According to Weber at Georgia Institute of Technology, “The ultimate goal [of the research] is to set a standard so the industry can self-regulate and the companies can have their 3D printers tested and they can try to meet this standard and they can label their printer as a green printer or a low-emission printer.”

Some work in this regard has already been done. There is an ANSI/CAN/UL standard for testing and assessing particle and chemical emissions from 3D printers, introduced in 2019.

Just how much should you be breathing in?

Unfortunately, the research to date is incomplete. The harmfulness of FDM emissions depends on the operating environment and the length of exposure. One 2021 study found that an exposure time of one hour or less doesn’t appear to negatively affect human health, but that those working 40 hours per week or more around 3D printers could risk developing respiratory illness. That leaves a wide gray area between one hour and 40.

Chemical Insights, however, does have a chart of the maximum airborne concentration of 3D printer fume chemicals. Although not specifically stated, you wouldn’t want to go above these levels and should stay far below. For example, maximum concentration of benzene is 60 parts per million (ppm) in indoor air and naphthelene is 9 ppm.

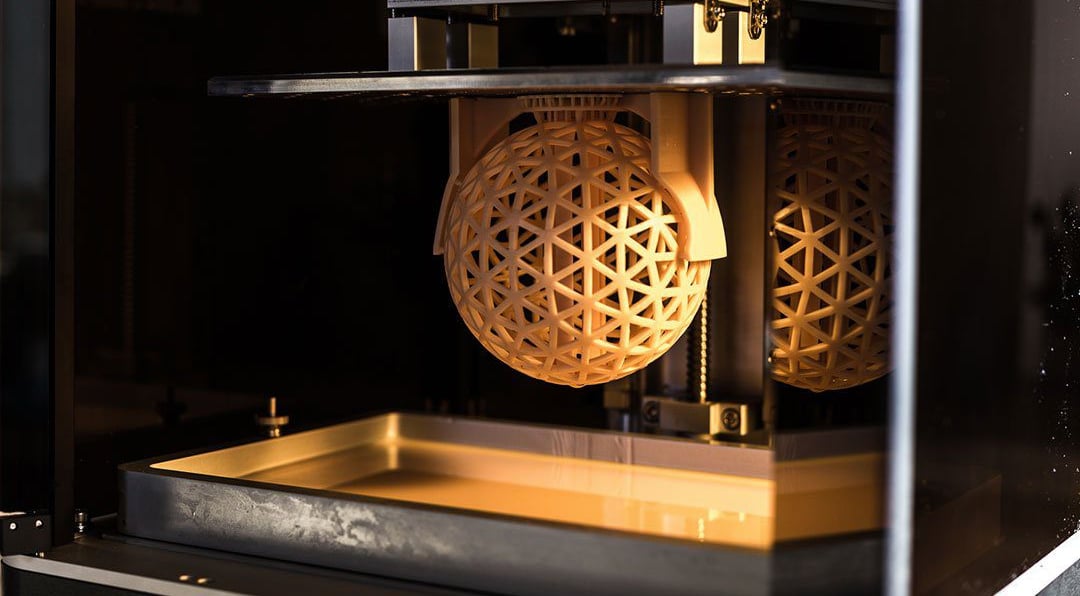

Emissions from Resin 3D Printers

Resin or stereolithography (SLA) 3D printing is another popular printing technology. Instead of plastic, it uses liquid resins which it hardens into solid objects using a laser or light source. But this difference in technology and materials doesn’t mean SLA doesn’t produce emissions as well. In fact, if you have a resin printer you know the smell is stronger than FDM.

SLA resins are toxic in themselves so you shouldn’t be surprised to find that they also produce harmful compounds during printing. However, there’s a significant difference in the emissions between SLA and FDM printers.

SLA 3D printers produce very little PM, even during the post-processing steps of washing and curing. A Chemical Insights study found that SLA particle emissions remain at or below background ambient particle concentrations. This stands in opposition to FDM printing, which produces high PM emissions.

On the other hand, VOC emissions from SLA printing tend to be very high, generally 3 to 6 times greater than those from FDM printers. The types of emitted VOCs are different from FDM as well, since in FDM most VOCs originate from additives or filament materials. VOCs are emitted during both SLA printing and post-processing.

More than a dozen VOCs emitted by SLA printers are listed as chemicals of concern, the study found. Among them is formaldehyde, a well-known carcinogen, that was emitted during all processing steps.

The study notes that SLA emission rates and estimated office exposure levels for chemicals of concern are below dangerous levels listed in regulations. That said, the researchers note that continued exposure to SLA printers’ complex mix of emissions could cause “strong irritation” in human respiratory systems.

Note that the Chemical Insights study monitored resin printer and curing machine emissions during operation with the lids down, so even though your SLA printer is enclosed, fumes do escape.

Printer Settings for Lower Emissions

On top of printer technology, material, and brand, printer settings can have a significant impact on the rate of PM and VOC emissions. Nozzle temperature seems to be the most important deciding factor. Research has found that – depending on the material – a higher nozzle temperature could make the PM emissions rate up to 10,000 times higher.

For a more detailed evaluation, we can look at a study by the Brno University of Technology. The researchers compared the effects of printer settings on ABS, PLA, PET, and TPU printing. Their results show that there are optimal printer settings for each material that can ensure a successful print while minimizing emissions.

According to the study, each material produces less emissions when printed with lower nozzle temperatures. As such, from the respiratory health perspective, the researchers encourage printer operators to use the lowest possible nozzle temperatures, even those below manufacturer recommendations.

The study also found that the nozzle diameter can have a notable effect on both emissions rate and particle concentration. For ABS, PET, and PLA, they found that using a 0.4mm nozzle produces the least amount of PM. TPU is the odd one out of the bunch since with it increasing the nozzle size to 0.6mm pushed the emissions lower.

The results further showed that material flow or printing speed had either a negligible or no effect on emissions. As such, the extruder settings are the most significant emissions factor, at least with FDM printing. Yet another study, looking at ABS and PLA printing, discovered that heated build plates won’t increase emissions and may in fact be useful for increasing particle size, making PM mitigation easier.

No similar studies have yet been performed on all FDM materials or other printer technologies. It would stand to reason that other printer technologies, like SLA, also have printer settings that produce the lowest emissions. However, this hasn’t yet been conclusively proven.

Best Practices for Cleaner Air

Although all of the studies we mention used various methods to determine 3D printer emissions and there’s no consensus yet on how long, how often, or how much you can breath in before 3D printer fumes are likely to effect your health, there is agreement that you should do everything feasible and practical to not breath in printer fumes.

The scientists carrying out 3D printer emissions studies point to several methods operators can use to clear the air in their workspaces. For the greatest effect, they recommend using as many of them as possible simultaneously. In other words, don’t rely on just an air filter in an enclosed printer room. Couple this approach with outside ventilation.

Lower your exposure to harmful emissions with:

- Ventilation

- Enclosures

- Air Purifiers

- Air Monitors

- Print slower

- Print cooler

- Opt for PLA

Ventilation

Practically all researchers point to proper ventilation as the most important method to mitigate air quality issues. You should place your printers at a well-ventilated location, with fan-operated exhaust vents producing the best results. You should always direct any ventilation systems to blow the air outdoors.

All ventilation systems should have proper air filtration systems to accompany them. It’s recommended to use high-efficiency particulate air (HEPA) filters, which can remove up to 99.95% of all particle emissions. To eliminate VOCs, activated carbon filters are the optimal solution.

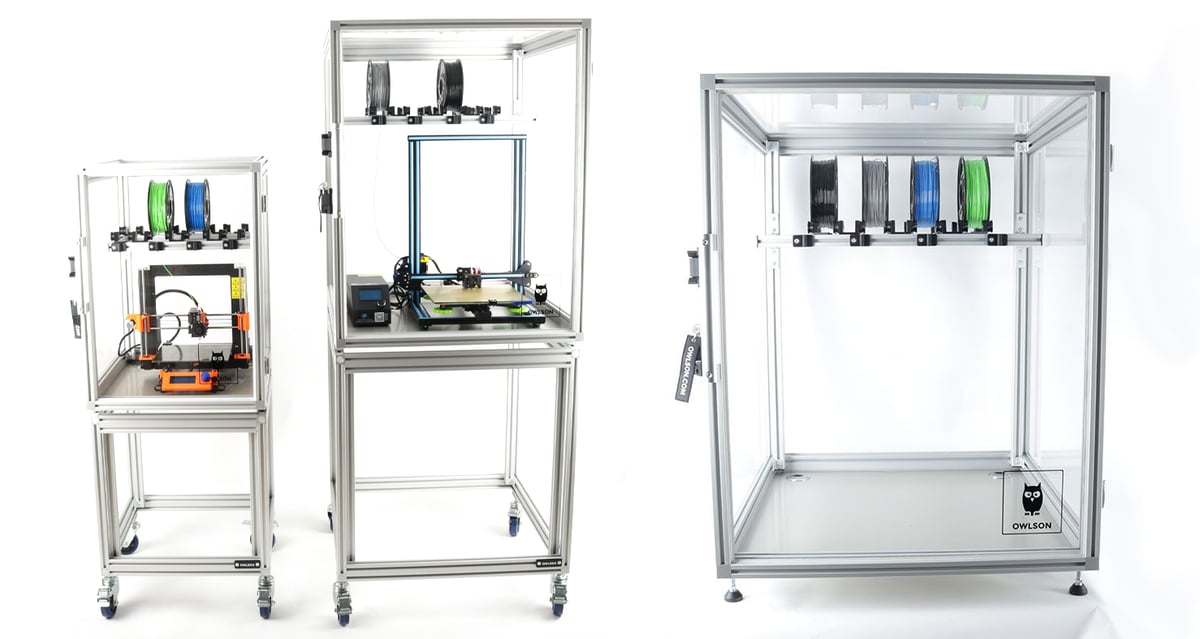

Enclosures

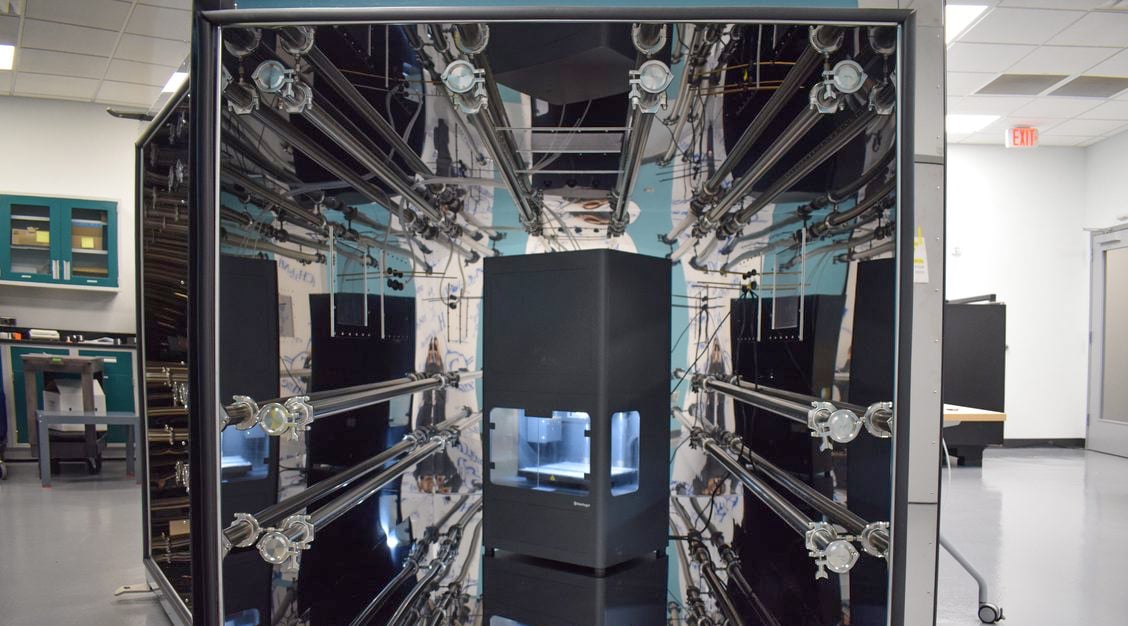

Placing the printer in a very large space can help combat emissions exposure through simple dilution of PM and VOC concentrations. However, the preferable option is to put the printer in a small ventilated enclosure with an air filter. This is a fairly simple method to lower your exposure to potentially harmful emissions. However, keep in mind that most 3D printer enclosures are simply intended to keep heat in, not emissions.

Look for a printer that has a filtered enclosure or put your printer inside a filtered enclosure. These air-tight, filtered boxes are available from a wide range of manufacturers and there are also DIY methods.

Research shows that placing a desktop 3D printer inside an enclosure with filtered ventilation reduced particle emission rates by 97%.

Air Purifiers

Air purifiers are devices that use a fan to suck air in and pass it through various filter and sanitizing steps to remove pollutants and contaminants. They can be useful in improving air quality in 3D printer workspaces, but you shouldn’t rely on them alone — particularly if you’re using a small device. Ensure your air purifier has the appropriate HEPA and active carbon filters. Shop carefully for air filters since those designed for dust and pollen may not be sensitive enough to remove 3D printer particulate matter or VOCs. Replace the filters on these machines regularly.

Air Monitors

Air quality monitors help you track the amount of potentially harmful chemicals in your workspace. However, studies vary on whether consumer-grade monitors are sensitive enough to detect the tiny particles emitted during 3D printing. One study shows that the vast majority of material emitted from filament as solid particles (particulate matter) were in the size range of 0.05 to 0.2 microns. Most home air quality monitors can only detect particulate matter down to 1 to 2.5 microns (labeled PM1 to PM2.5). However, there are monitors that can detect down to 0.1 microns (labeled PM0.1).

Some studies note that reliability is always an issue with air quality monitors, even in high-grade research settings. However, if your monitor shows a PM concentration of higher than 35 ug/m3, you should start using one or more methods to remove emissions from your workspace.

Special Environments: Print Farms & Classrooms

The studies we’ve covered so far have studied single 3D printers operating in environments comparable to an office or a small workshop. But there are two common 3D printing environments that could raise additional concerns — print farms and classrooms.

3D printing farms are popular among large-scale additive manufacturing operations. A print farm can have dozens of 3D printers operating in a single large space. It’s also increasingly common to find 3D printers in classrooms, as they can be useful in education. In such an environment, though, they could have a negative impact on children’s health.

Let’s examine both these scenarios and see what considerations there are regarding air quality.

3D Print Farms

Everyday logic suggests that more 3D printers operating in one space would significantly increase their emissions. This is indeed correct. Although the exact details depend on the number and type of printers and their operating hours, a Health Hazard Evaluation (HHE) report by the National Institute for Occupational Safety & Health (NIOSH) found that PM and VOCs could build up in printing areas to potentially dangerous levels.

The HHE report examined one print farm operating 10 desktop-scale FDM printers using PLA and ABS filaments. During their two-day evaluation, NIOSH determined that the company’s staff was exposed to potentially harmful chemicals and particles in the printing and post-processing areas. However, their levels remained within regulatory standards and the potential for any health hazard remained unknown.

NIOSH also notes that this situation reflected the operating conditions at the time of evaluation. Changing printer settings or adding more printers would likely change the emissions situation. Additionally, staff didn’t occupy the printing and post-processing areas for extended periods, which could partially explain the low personal exposure.

The HHE report states that NIOSH didn’t at the time see a need to recommend operational changes. This is partly due to the company’s functional emissions mitigation measures, such as keeping doors leading from one area to another closed. However, NIOSH notes that the company could employ ventilated and filtered Plexiglass enclosures around printer shelves. Such a solution can reduce PM concentration by up to 99% and VOC concentration by up to 70%.

Schools & Classrooms

According to an EPA study on 3D printer emissions, children may potentially be particularly vulnerable to emissions from 3D printers. The study found that the predicted pulmonary surface area covered by particles from 3D printing was higher in children aged between 9 and 18 when compared to adults.

The EPA suggested this may be due to both exposure and the ongoing respiratory tract development in children. However, the agency noted that further study on 3D printing and emissions mitigation technologies and emissions exposure in children is necessary before conclusive assessments can be made.

Underwriters Laboratories offers an 8-page guide to best practices for 3D printers in schools.

Additionally, another study found that the nature of the school environment may be in itself effective in mitigating 3D printer emissions. According to the researchers’ estimates, a school setting has the lowest potential for harmful chemical and particle exposure when compared to office and home settings. The study suggested that this is due to the large spaces and effective ventilation systems in schools.

These results indicate that although children appear to be more vulnerable to 3D printer emissions, existing ventilation systems in schools could be enough to prevent hazardous exposure. However, implementing additional emissions mitigation methods when placing 3D printers in classrooms can certainly do no harm in protecting children’s health.

The National Institute for Occupational Safety and Health recommends that 3D printer users protect themselves by using materials with lower emissions, using enclosures for 3D printers and ventilation to capture chemical emissions, and reducing time spent near the printer while it is running.

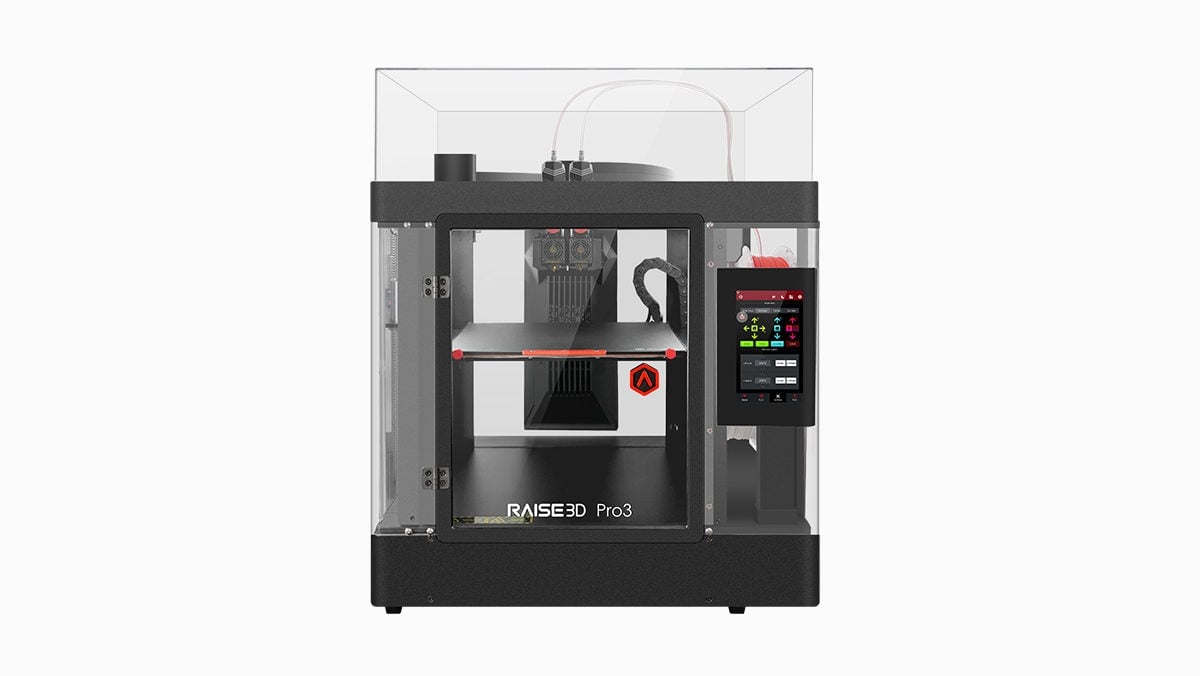

3D Printers with Built-In Air Filters

Most consumer 3D printers do not come with standard air filtration while more professional models see it as a selling feature. Industrial 3D printers, on the other hand, are intended for factory-type environments with workplace-regulated safety protocols.

Depending on how much you print and where, it may make sense to buy 3D printers that already features a filtration system.

Desktop FDM Printers with Built-In or Add-On HEPA and/or Carbon Air Filtration

- Zortrax Inventure

- Raise3D

- UltiMaker S7, S5, Method

- Bambu Lab

- BCN3D Epsilon series

- FlashForge Adventurer 4, Creator 3

- Tiertime UP mini 2 ES

- Dremel DigiLab 3D45

HEPA filter 3D printer caps are also available from third-party manufacturers, including Sotec3D.

Lead image source: How Lensrentals Uses 3D Printing

License: The text of "3D Printing Fumes & Air Quality – A Practical Guide" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.