Compared to other manufacturing methods, one of the greatest advantages of 3D printing is that it drives innovation by enabling us to make things that previously could not be made.

To those familiar with the love affair between dentistry and new technologies, it should come as no surprise that our profession has embraced 3D printing so much so that nearly a dozen 3D printer manufacturers now offer a selection of specialized dental 3D printers.

The range of applications is wide enough to sustain an entire 3D printing hardware and materials market, while new applications are being tested and adopted at a staggering pace. From implant placement guides to full dentures, and from impression trays to custom-made titanium components for implant restoration, it does seem that the future of dentistry is full-on CAD/CAM.

How the Dental Aligner Was Born

A great example of 3D printing driving innovation in dentistry was the eureka moment Muhammad Ziaullah Khan Chishti, aka Zia Chishti, must have had while undergoing Orthodontic treatment in his early 20s. Chishti, a BA in computer science and economics, envisioned wearing a series of clear plastic appliances over his teeth, each one driving small, incremental movements towards the desired outcome, instead of the ‘traditional’ procedure with metal brackets and stainless steel wires to brute force the same tooth movements.

Chishti worked tirelessly on his idea and eventually co-founded Align Technology in 1997, the first company offering clear orthodontic aligners called Invisalign. By 2001, his medical device company was listed on NASDAQ with a $1 billion valuation.

In 2022, there are many competitors in what is now a $3.1 billion market for aligners, projected to grow at a compound annual growth rate of almost 30% to 2030, most of those based on the original Invisalign concept.

Aligners Are More Complex Than They Seem

Although low-cost 3D printing and basic CAD knowledge are indeed all the tools one needs for DIY orthodontics – as brief internet sensation Amos Dudley, a college student who made his own aligners, clearly demonstrated a few years ago – it is for good reason that it takes another 3 to 4 years of studies and clinical training after becoming a dentist to be an orthodontist.

Rearranging the positions of the teeth is not just a simple CAD exercise. It’s a complex bio-mechanical intervention that should be carefully designed by an expert while considering a large number of clinical factors.

At the very least, a practitioner must ensure that the teeth, gums, and jawbones are in a healthy condition and the patient undergoes a radiographic examination before even thinking of having orthodontic treatment. Otherwise, as with any fixed or removable appliance placed in the oral environment, there is an increased risk of caries (decay) and gum disease.

Then, considering the whole process takes many months, the oral health status should also be monitored during the treatment so that any sign of cavities or gum disease, which may not have been present at the onset but developed later can be detected and dealt with as early as possible. Without any intention to scare readers away from clear aligners, this is still just scratching the surface of the list of things that may go wrong.

Regardless of how it is achieved, orthodontic tooth movement is a biomechanical process that involves the deconstruction of the bone supporting the teeth in the direction towards which tooth movement is made. The tooth may be shifted in that direction while new bone is formed in the other direction behind the tooth. This is a delicate process that should be carefully planned in order to avoid pushing the teeth too far, too fast, which may result in severe complications, such as resorption of the tooth roots, exposure of the roots beyond the boundaries of the jawbones, unwanted tooth rotations instead of translations or receding gums, increased tooth mobility or even eventual tooth loss.

All of the above, and more, are the reasons why the dental profession strongly opposes the idea of direct-to-consumer business models of providing clear aligners. Most companies in the market, including Invisalign and Impress require dental screening, including radiographs, and monitoring during the treatment; tooth movements are planned by experienced Orthodontists who are always available to advise and guide the providing dentist; and any general dentists providing such treatment must be trained on it first. Popular clear aligner provider Candid announced in January it’s closing its direct-to-consumer business and all 45 of its studio locations and pivoting to focus on its virtual telehealth model that dentists and orthodontists use to treat clear aligner cases remotely.

“We founded Candid to democratize high-quality orthodontic care, prioritizing excellent outcomes and a great patient experience over attractive but unsustainable growth,” Candid CEO Nick Greenfield said in a statement. “We also listened to our patients, who overwhelmingly told us that … they also wanted to straighten their teeth in the care of an in-person doctor.”

Another common provider, Smile Direct Club also offers physical locations where you can have your teeth scanned, doctor-prescribed remote impression kits, and a partner network location of dentists. They enable virtual Smile Check-ins and 24/7 access to their dental care team – all overseen by your prescribing doctor. This is their plan to limit or eliminate the sometimes costly in-office dental visits.

Dental alignment is still out of reach for so many who need it. However, as more 3D printed dental alignment options drive down the costs of treatment, more dentists and orthodontists are opting to create them in-office.

Let’s look now at how dental aligners are made.

How 3D Printed Clear Aligners Are Made

Although there are lots of options for 3D scanning, 3D printing the molds, and forming the aligners, the workflow of making clear aligners is the same. The newer process of 3D printing the clear aligners directly, however, cuts out the molding and thermoforming steps and speeds up the whole process. Let’s first take a look at the most used method, making aligners from 3D printed dental molds.

Step 1. Impressions

The dentist first records impressions of the patient’s teeth (technically called their dentition), either in the conventional way (biting down on a tray of dental molding material) or by using an intraoral 3D scanner, which is just as accurate but more comfortable as a process. Conventional impressions are cast in dental plaster and then digitized using a 3D scanner. Intraoral scans of the dentition are exported as STL files to the 3D printer.

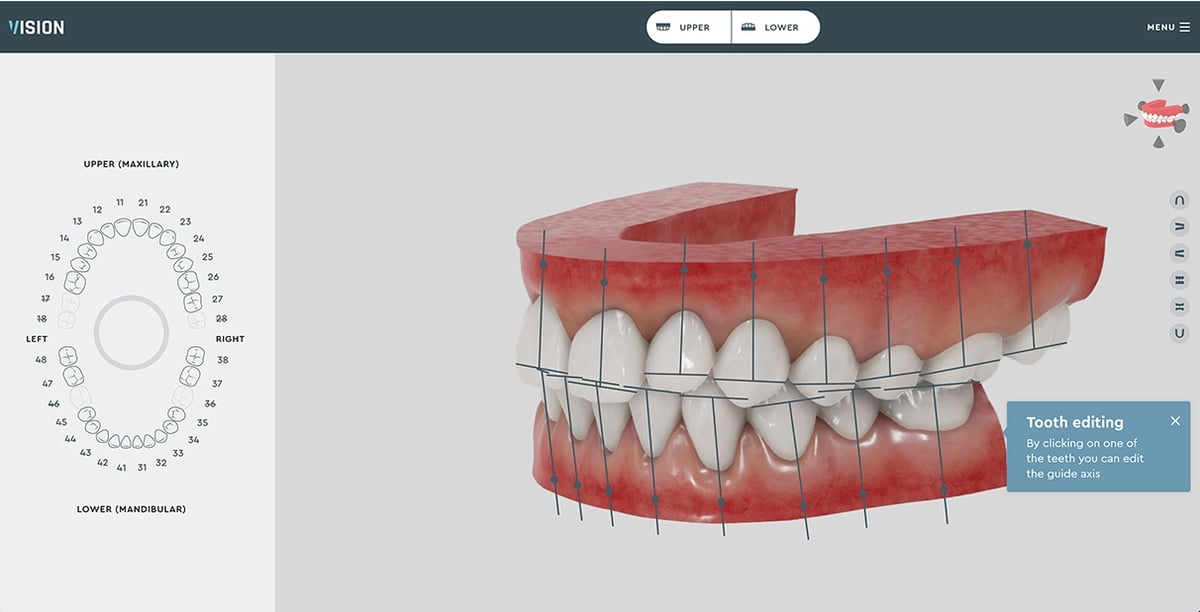

Step 2. Design

Modify the 3D models of the dentition using either specialized dental software or any CAD software, such as Autodesk Meshmixer. This step is by far the most critical as tooth movements must be done in specific increments and take into consideration clinical information, such as the direction of movement or angulation, the morphology and size of the roots of the teeth, the surrounding bone thickness and density, force vectors, and the occlusion (the way that teeth of the upper and lower jaws bite down together). The output of this process is a series of 3D models of the dentition each implementing small tooth movements towards the desired final tooth positions.

Step 3. 3D Print Models

The number of models to print will depend on the magnitude of the desired tooth movements. Small corrections on the position of one or two teeth may be achieved with just a few models, while more complex movements of a large number of teeth may require up to 40 or 50 models, especially considering that there isn’t always enough space for the teeth to simply shift into the desired positions: the neighboring teeth may have to be ‘pushed out of the way’ first, then repositioned back in line once the misaligned tooth has been moved to the correct position. A timelapse video of the whole process in these cases really would look like a well-orchestrated dance of the teeth in one’s mouth!

Step 4. Form the Aligners.

Once the series of models required are 3D printed, they are used for the fabrication of the actual clear aligners, each one to be worn by the patient for a couple of weeks. The clear aligner itself is not 3D printed although that’s an option covered below. More typically, the aligners are made in thermoplastic material, using a technique called thermoforming, or more specifically vacuum forming: a sheet of material is heated under an electric heating element until it becomes pliable, and when it reaches the right temperature it is pressed against the dental model using suction. After cooling down it can be cut from the dental model in a specific way without losing its shape; it is manually trimmed and polished with rotary instruments and is ready for use.

Aligner Advantages over Traditional Braces

Beyond the obvious aesthetics and comfort of not having to eat, smile, and interact with other people with a mouthful of steel wires, clear aligners also offer lower costs, quicker delivery times, and eliminate complications, such as brackets debonding or the wires snapping. But perhaps more importantly, they offer dental professionals the ability to make quick and easy adjustments to the overall treatment plan depending on the progress made.

However, there are disadvantages as well: non-compliance to the instructions of use is easier when the aligner can be removed from one’s mouth, as opposed to brackets and wires, therefore requiring fewer emergency visits to the orthodontist. Restrictions in daily diet also do not exist, compared to traditional braces.

There’s also the common occurrence of the ‘invisible’ removable appliance being lost, misplaced, forgotten, damaged, or even ‘eaten by the dog’.

Luckily, replacement is easy, though by the time it is delivered there may be some relapse of the tooth positions setting the whole process backwards.

It is also generally accepted that aligners are indicated for mild to moderate cases, not severe. In other words, clear aligners are not for everyone.

Directly 3D Printing Aligners

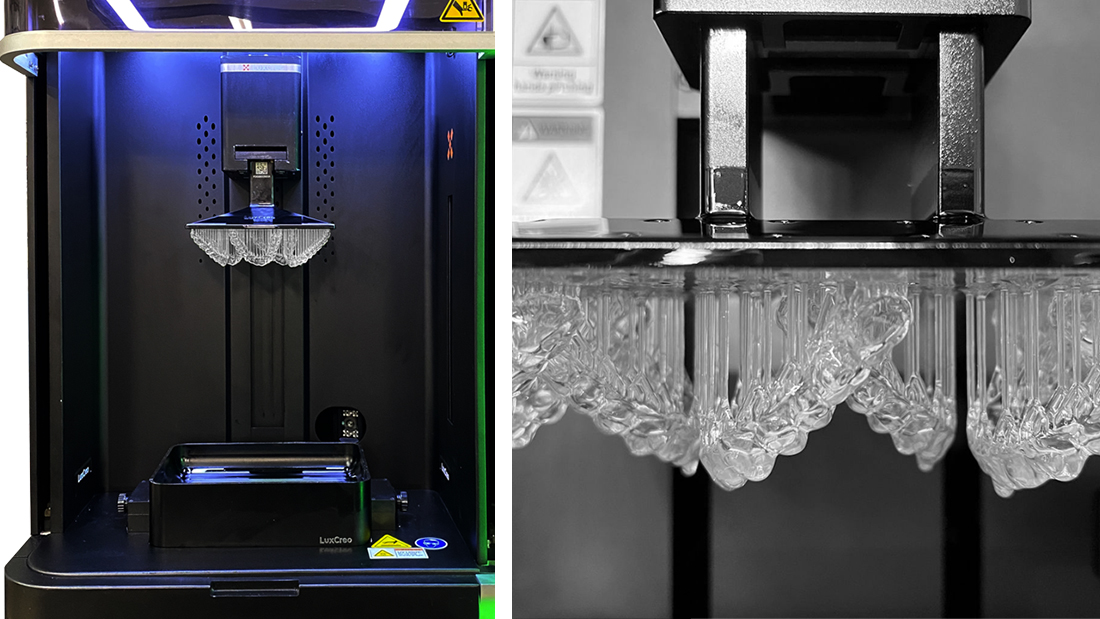

More recently, it has become possible to 3D print the aligners directly in resin, without a need to 3D print a series of dental models first. Resin 3D printers may be able to produce more accurate aligners than thermoforming, and six to 12 aligners can be printed at once, greatly accelerating the entire process.

However, this is a new technique and there is currently limited evidence on the clinical performance of these aligners. Plus, there are only a few companies claiming to have a clear bio-compatible material for the direct 3D printing of aligners with FDA and CE approval for long-term oral use. Always make sure your materials have proper certifications for exactly the application you need.

South Korean company, Graphy declared in 2021 that it was the first company offering clear aligner resin material called Tera Harz TC-85 approved by the US FDA and CE in Europe. Chinese company LuxCreo with American headquarters in California offers Lux 3+ dental printing solutions for clear aligners.

US-based Desktop Health has a 3D printing clear resin for use to create so-called “first aligners”, which are the device used after an orthodontist removes a patient’s brackets to hold teeth in place, before the treatment is completed with a series of thermoformed aligners. This resin is also used to 3D print clear surgical guides, orthodontic bite splints, and night guards. Another company, Formlabs, also has a clear resin, Dental LT Clear Resin, just for splints and night guards.

It does seem however very likely that direct 3D printing will become the standard of care in the future of ‘invisible’ orthodontics. It has obvious cost and time advantages, increased accuracy, and no waste material over the indirect process described above. Once this becomes the routine practice, it is very likely that more general dentists will feel ready to adopt the new technology and 3D print aligners in their own offices.

About the Author:

Dr. Andreas Artopoulos, DDS, runs Eversmile Dental Center in Cyprus. He holds an MSc in both Prosthetic Dentistry and Maxillofacial & Craniofacial Technology. He is also the director of ExMachina 3D Medical Modeling.

Lead image source: Smile Direct Club

License: The text of "3D Printing Clear Dental Aligners" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.