3D printing is firmly established in the highly innovative medical industry, which to this day makes up one of the largest markets in the additive manufacturing sector, second only to aerospace. The list of possible applications is long, including 3D printed drugs, prosthetics, implants, surgical tools, and of course medical models.

Although models have been used in medical care for centuries, patient-specific medical models generated from patient scans and confirmed by trained medical professionals bring a wide range of advantages over traditional models or 3D imagery, such as:

- Better insight into patient-specific anatomy

- Better medical diagnosis

- Better pre-operative planning resulting in shorter surgery time

- Simulation-based surgical training and education

- Development of patient-specific surgical guides and tools

- Development of patient-specific implants

- Better patient counseling and education

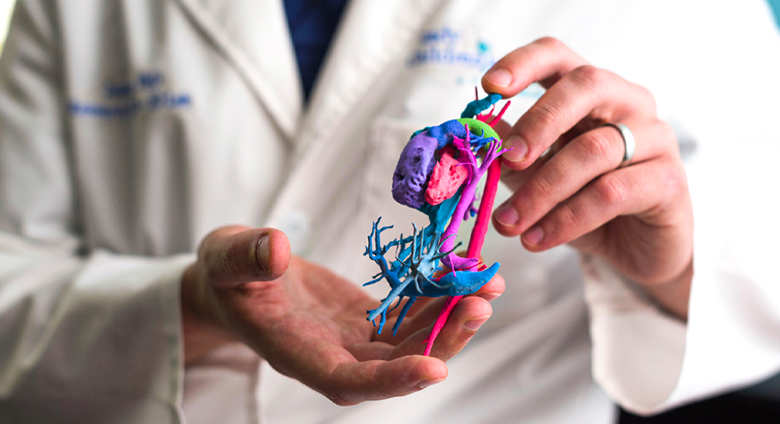

For everything from rare tumors to cardiac models incorporating complex blood-flow fluid dynamics, life-size and extremely accurate 3D printed medical models improve the quality and safety of surgical procedures by enabling physicians to plan and even practice various approaches, as well as size or pre-fit medical equipment. Time saved in the operating room reduces the likelihood of additional procedures, and has been shown to improve post-operative outcomes and lower the duration of patient hospital stays.

In fact, a 2022 study found that 3D printing-enabled pre-procedural planning and training are “transformative” in medical care today.

Improving Patient Care

Patient-specific models allow for greater personalization of healthcare, improving patient satisfaction, lowering anxiety, and reducing recovery time. They communicate to patients information about their specific condition when medical terminology alone may be confusing.

Take for example the Cath Lab at the Children’s Hospital Colorado. Cardiologist Jenny Zablah uses 3D imaging technology and in-house 3D printing to create what she calls ‘souvenir models’ as education tools for anxious parents. According to her colleague Gareth Morgan, “a lot of families really don’t understand what’s wrong with their child. But I can bring this to a family and say, this is your daughter’s aorta. It looks like this, here’s the problem, and here’s what we’re going to do. That’s powerful. When Jenny brings these models down, it’s tears, it’s hugging. It’s never been explained that way.”

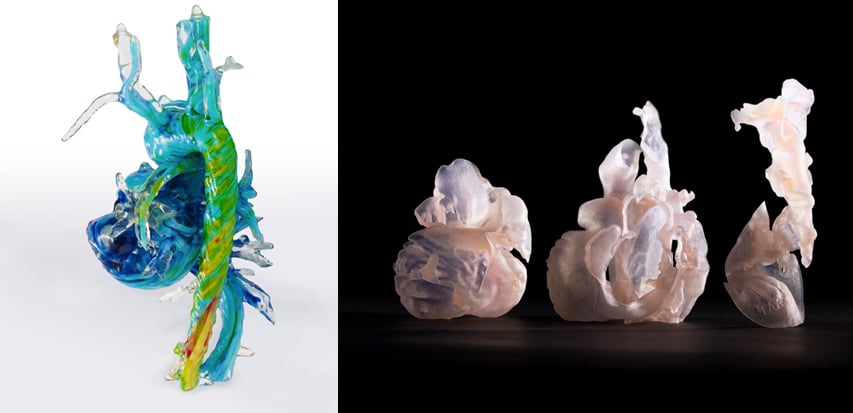

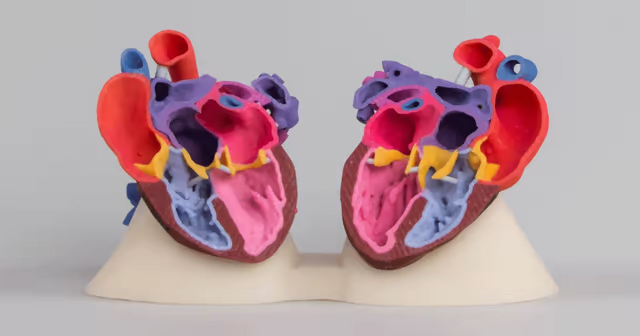

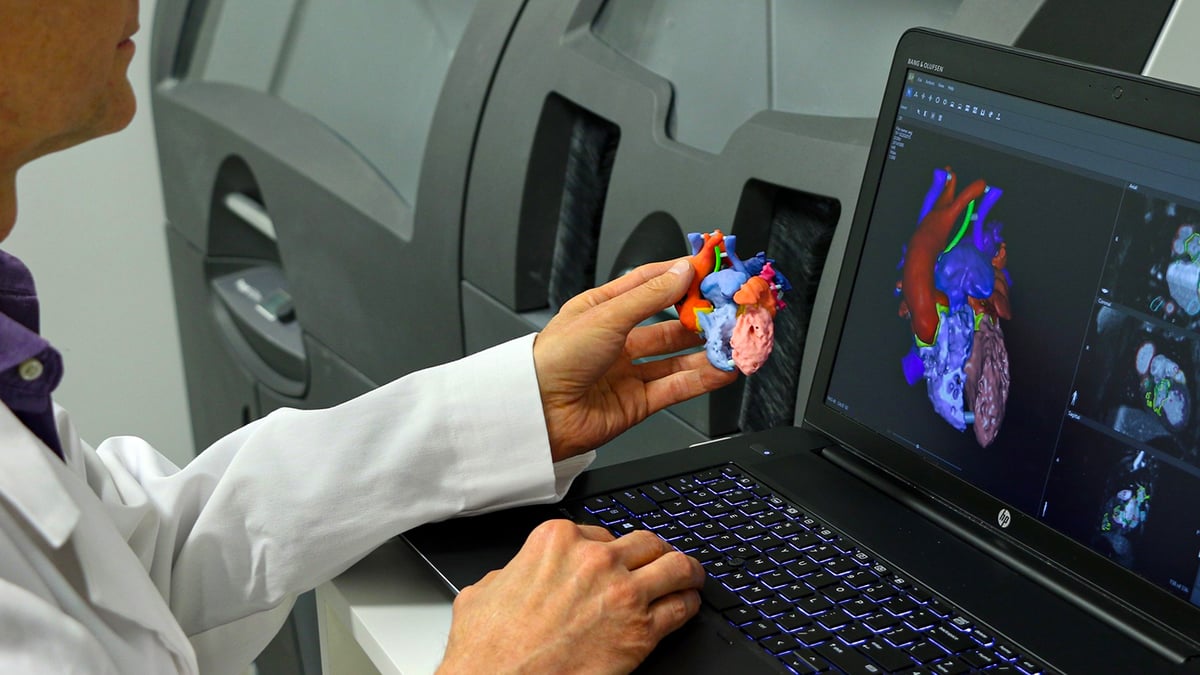

Beyond patent, 3D printed anatomical models help doctors diagnose and plan treatment. In one case study of a four-year-old child born with a heart defect, doctors created several models for pre-operative analysis and surgical planning together with printer manufacturer Stratasys and the University of Colorado. Using a scanning technique called 4D Flow MRI the team could analyze the patient’s extremely complicated blood flow through the heart cavities and vessels, which was then processed and printed in full color (below). Next, doctors had a patient-specific 3D printed model printed and cut into sections for a better understanding of the cardiac anatomy.

Models also are used to plan post-operative care and to predict what long-term issues the patient may encounter. In a case study by 3D printer manufacturer 3D Systems, Israeli orthopedic specialist Dr. Vidal Barchilon says: “The ability to hold the life-size 3D model enables me to better understand the structure of a fracture, plan an operation, and try to understand what the future limitations of the fracture may be.”

Barchilon, head of the Department of the Shoulder Orthopedic at Meir Medical Center in Israel, says pre-operative planning with 3D printed models shortens the procedure time because he can confirm compatibility of plate and screw measurements.

Saving time is especially critical to hospitals today. According to a recent study, hospitals may face a huge backlog of elective surgeries, especially orthopedic cases, by mid 2022, due to the COVID-19 pandemic. Any new processes that save time and improve outcomes will be in high demand.

How to Make the Model

Medical Models in 7 Steps:

- Acquire patient-specific medical images (MRI, CT, ultrasound, etc.) in Digital Imaging and Communication in Medicine (DICOM) standard format.

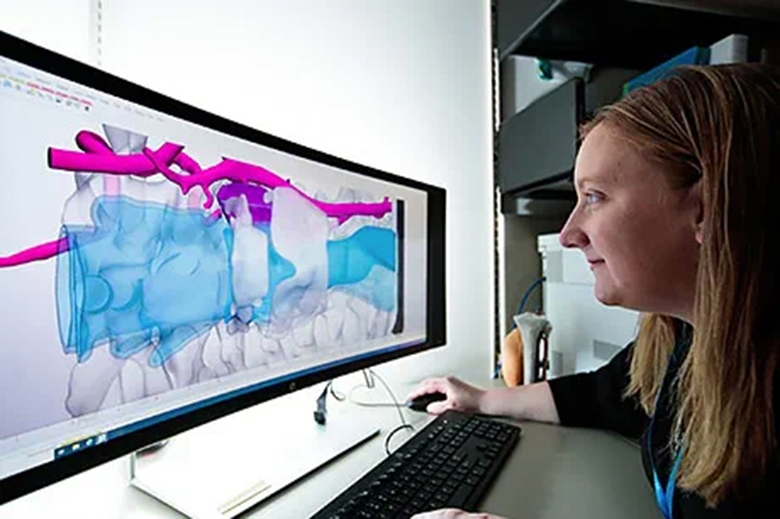

- Process the DICOM images using a combination of software and human expertise to define the anatomy of interest and generate a 3D file.

- Secure approval of 3D file from a certified professional and generate a 3D printable file called an STL.

- Process the STL file for printing, including generating support structures.

- Print the 3D file in-house or send to a third-party printing service.

- Post-process the print (if printing in-house) to remove supports, polish, label, etc.

- Provide to surgeon, patient, doctor or medical student.

What the model will be used for is always the starting point. Patient education models may not need to be as exact as surgical planning models. Practice models may require different materials or full color. Models used for diagnostic purposes need to be made with regulatory guidelines in mind.

Next, it’s the data. CT scans, MRIs, and other medical imaging data can be sent directly to third-party providers (such as Materialise’s HeartPrint, a service that 3D prints heart models in a range of materials and colors) or combined in software to generate a single, printable file.

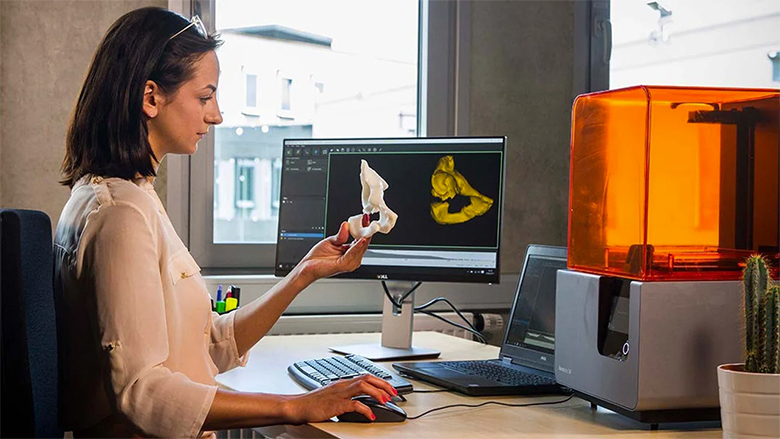

Although speciality software focused on medical model applications isn’t strictly necessary, several solutions offer attractive features, and several are approved by the US-FDA for the propose of generating medical models for diagnostic purposes. (See the “Regulations Effecting Medical Models” section below.)

For example, Mimics inPrint from software and printer manufacturer Materialise, integrates into your hospital’s workflow and converts medical image data (DICOM files) to 3D anatomical models. Another offering from the company is its software, D2P (DICOM to Print) 3D Model Software that enables surgeons, radiologists, lab technicians, and device designers to create diagnostic-quality digital 3D models and physical 3D prints.

3D printer and software maker 3D Systems’ Virtual Surgical Planning (VSP) software solutions for cranio-maxillofacial, orthopaedics, and extremities are used for pre-surgical planning and for making patient-specific models, guides, and templates. Also US FDA-approved, VSP services begin with an online planning session between 3D Systems’ biomedical engineers and the surgeon; patient-specific models, surgical guides, and instruments are designed, and 3D printed for use within the sterile field.

Other software options with FDA 510(k) clearance as a medical devices, include Synopsys ScanIP Medical, which is used for simulating and evaluating pre-surgical treatment options as well as generating 3D printing files for models; and Coreline Soft, an AI-based imaging diagnosis solution, specializing in lungs and coronary artery systems.

One of the biggest barriers to entry for establishing a point-of-care medical models program is finding and funding the dedicated, trained professionals for segmentation of the DICOM data, according to Evan Hochstein, senior healthcare solutions engineer at Stratasys.

Reacting to these barriers, a small community of technologists has formed around the prospects of an open-source model fabrication workflow, sharing their knowledge on platforms like Embodi3D to help doctors in the biomedical community reap the benefits of the technology. Of course these applications have limited patient-care purposes, as anything with the intention to be commercialized or used in the operating room are still subject to strict regulation.

In-Hospital 3D Printing Labs

3D printing at the point-of-care makes sense for a growing number of hospitals worldwide that have established their own centralized 3D printing facilities.

The Minneapolis-based Mayo Clinic started 3D printing in 2013. Mayo created a dedicated anatomical modeling lab using 3D printing and is now making 3,000 models per year. In addition to surgical guides and patient education, the models are used to make custom cutting guides for surgeons as well as help orthopedic surgeons design new implants.

The US Veteran’s Administration now boasts a network of 33 3D printing labs in its hospitals coast to coast, focusing mainly on custom prosthetics but also making patient-specific medical models.

The Memorial University of Newfoundland, Canada, started its MED 3D initiative in 2017, and since then it has expanded to a rural 3D printing network. The project’s aim is to both teach students and help patients in remote areas, and their lab contains a dozen 3D printers from various manufacturers, including Stratasys, Ultimaker, and Formlabs.

In-hospital labs can range is complexity from one printer to several representing different technologies. Stakeholders can come from every hospital department and specialty.

Point-of-Care Printing Labs

- Mayo Clinic 3D Anatomic Modeling Laboratories, Minn., US

- ProMade PoC (Point of Care) Center, Hospital for Special Surgery, N.Y., US

- US Veterans Health Administration, 3D Printing Network, US

- Seattle Children’s Hospital 3D printing lab, Wash., US

- Tampa General Hospital, Tampa, Fla., US

- SJD Barcelona Children’s Hospital, 3D Unit, Spain

- Hospital Gregorio Marañón, Advanced Planning and 3D Manufacturing Unit, Madrid, Spain

Ordering Patient Specific Medical Models

There’s no shortage of third-party 3D printing companies capable of producing accurate and detailed medical models quickly. Some have self-service portals where you upload your files and receive a quote, such as Craftcloud, which ensures data privacy and features many of the leading 3D printing companies as providers.

There are also 3D print-on-demand services that specialize in medical models, including from the printer manufacturers themselves. For example, Stratasys and 3D Systems both have on-demand manufacturing services for medical models. 3D Systems also offers a library of pre-designed anatomical models and specialized software.

Several 3D printing companies do nothing but medical models. You upload your patient-specific 2D images to their portal and within 48-72 hours the company promises precise models. Among these specialty 3D printers are:

- Axial3D (EU & US)

- Osteo3d (India)

- Materialise (EU)

- Lazarus 3D (US)

- Onkos Surgical (US)

- 3D LifePrints (EU)

- Medairum (Singapore)

Best Printers for Medical Models

There is a wide range of printers used for medical models, in fact, even budget printers can generate realistic models for patient education. However, some printer manufacturers specifically target this market and therefore can provide knowledgeable support and training when you’re setting up your own lab. We focus on just those here.

Stratasys

With the J850 Digital Anatomy, Stratasys recently unveiled an update of its capable J750 Digital Anatomy 3D printer which comes with expanded material capabilities and a print speed twice that of its predecessor. They also offer the J5 MediJet specifically for medical models and tools that can make models in multiple materials, multiple colors and using biocompatible materials.

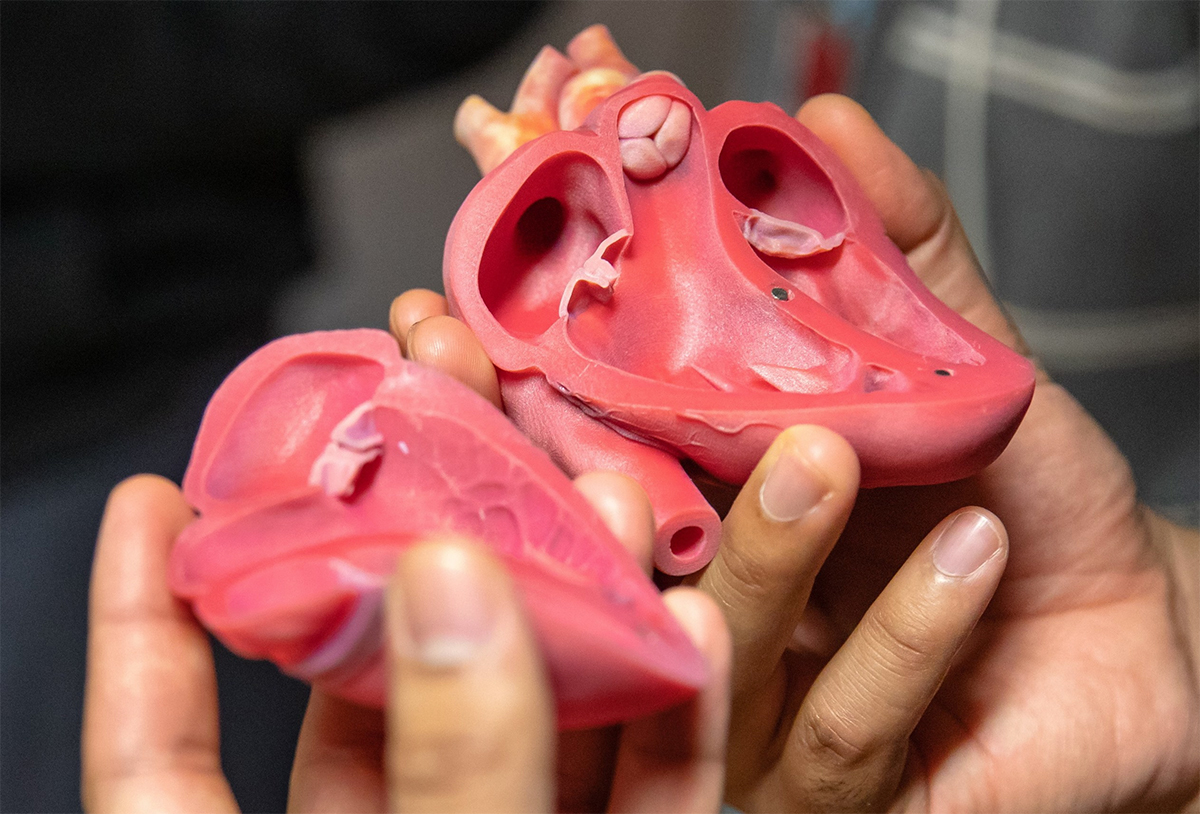

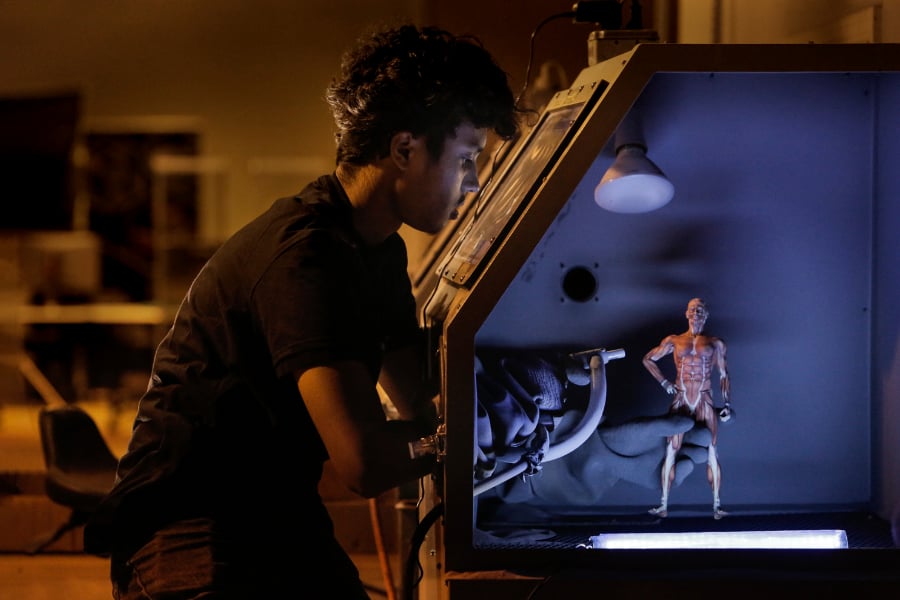

Digital Anatomy can produce prints that mimic bone and tissue in look and feel thanks to its three biomimicking proprietary materials GelMatrix, TissueMatrix and BoneMatrix . Complex material depositing patterns mimic porous bone structures, fibrotic tissues, and ligaments providing realistic feedback when cutting and drilling. The J850 Digital Anatomy printer offers full color, the ability to define transparencies and determine textures and finishes, and create an end product that’s as close to the real thing as possible. With its ability to print in multiple materials at once, it stands out in the printer market, catering to users that want to produce both visual and functional models.

The J5 MediJet 3D printer offers multiple materials and colors in one, and uses regulator-approved software and biocompatible resins that can be sterilized. It is for facilities and labs that aim to print detailed 3D anatomical models, along with drilling and cutting guides, and also for medical device manufacturers, and med schools. The J5 MediJet is also compact enough for small lab spaces.

In addition to printers, a printing service, and expertise, Stratasys offers to work with you to create a custom return on investment (ROI) analysis for 3D printing in your institution.

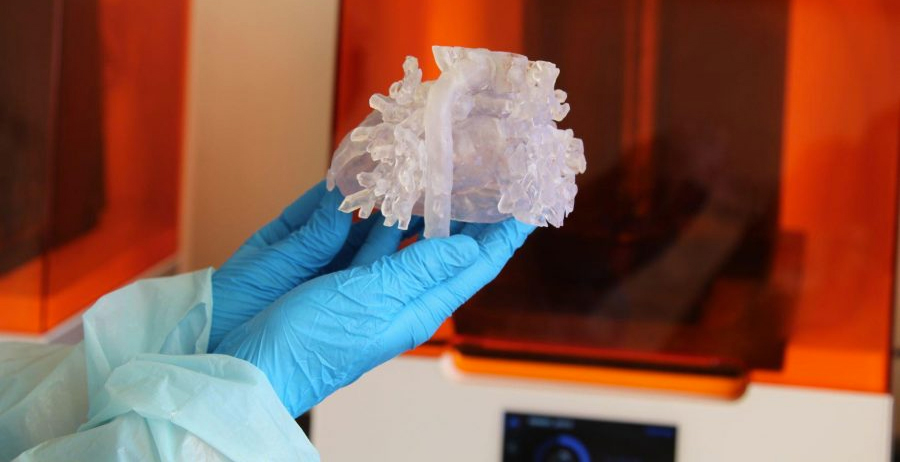

Formlabs

This resin 3D printer manufacturer has teamed up with GE Healthcare’s Advantage Workstation software to enable radiologists prepare 3D CT or MRI data then export using 3D Suite in a form that is ready for 3D printing on Formlabs printers. The manufacturer also offers frequent healthcare-related webinars. Download their informative white paper, “3D Printing in the Hospital“.

3D Systems

3D Systems has decades of experience in anatomic models. Whether you are looking for a printer or a service, the company has a wealth of knowledge to guide you. Even if you don’t have a 3D file, a 3D Systems engineer can process your medical imaging data and produce a patient-specific, 3D-printed anatomic model for you. Download their “Anatomic Modeling Solutions” brochure.

Mimaki

Mimaki 3D printers are also popular for medical modeling. Especially the 3DUJ-553, capable of printing transparent and in 10 million colors is a solid choice in the medical field.

Ultimaker

The Ultimaker S5 printer is certified by Materialise as a 3D printing solution to create orthopedic, maxillofacial, and cardiovascular models for clinical use when used in combination with Mimics inPrint software. It’s one of the more cost-effective options for medical models.

BCN3D

This printer manufacturer is also a popular choice for point-of-care medical model printing. Several health care case studies are available on its website.

Lifelike Materials for Medical Models

Depending on the application, you may want your medical models to mimic the texture of tissues and the hardness of bone. This would, for example, allow for more representative medical training and surgical simulations. Research is ongoing to create materials that more closely mimic the behavior of real tissues, but already several manufacturers offer materials that can be cut and sutured, and materials that mimic bone when drilled or sawed.

Some sections of models can be printed in clear or translucent material and in various colors so that different parts of the model can be seen and highlighted.

Although the material requirements are much lower models than for devices that would enter the body, both the biocompatibility and the sterilization compatibility need to be considered. Sterilization of the model is not required in all cases, however, it’s essential if the model is to be used in an operating room.

Limitations of Medical Models

The advantages of patient-specific 3D printed medical models are clear, but are the drawbacks?

As with everything in a hospital setting, cost is a consideration. Most medical insurances, while covering the costs of scans and X-rays, are slow to recognize the cost-saving of medical models. This is despite a study that found an average operating room time savings of 62 minutes per case and a cost savings of $3,720 per case when 3D printed anatomical models were used to prepare for orthopedic and maxillofacial surgery. The US Veteran’s Health Administration boasts even better figures, saying 3D printing technologies used for pre-surgical planning can “save doctors as much as two hours per surgery, or up to $9,600 in cost avoidance for the facility.”

At present, hospitals can outsource 3D printing of models or establish their own labs, which require a capital investment in printers and staff education, but enables a faster turnaround than outsourcing. Several hospitals defray the cost of models by partnering with medical schools or engineering universities with existing 3D printing labs.

A growing number of third-party 3D printing services print medical models from patient data, although data privacy concerns have lead many hospitals to opt for in-house solutions.

When it comes to the quality of medical models they are extremely accurate, depending on the technology used and the quality of the initial medical scans. Advances in 3D printing materials have resulted in soft, pliable, and arguably tissue-like medical models, but performing a surgery simulation on a 3D printed model will always pale in comparison to the real thing.

These two limitations are where the future of the industry lies – on the one side it’s the establishment of 3D printing in medical spaces to enable mainstream adoption of current applications. On the other it’s the continuous improvement through material and process innovations that mimic both structure and function of the organic part to a point where, ideally, printed and original tissue are virtually indistinguishable from one another.

Regulations Affecting Medical Models

The regulations affecting medical models depend upon their intended use, and for a specific application, these regulations should be checked and adhered to carefully. The FDA provides guidelines for 3D printing for medical applications on its website, and it regulates the use of products and software for such applications. Factors include whether the models will be used to make decisions about patient care.

Medical models used for diagnostic use may be considered medical devices and subject to regulations. The U.S. FDA considers 3D printed anatomical models that can affect/change diagnosis, patient management, and/or patient treatment as diagnostic tools and, as such, are Class 2 medical devices. The FDA requires that models marketed for diagnostic use be prepared using software that has received FDA clearance, such as Materialise Mimics InPrint or 3D Systems’ D2P (DICOM-to-PRINT).

In 2018, Materialise received FDA clearance to use 3D-printed medical models for diagnostics, and it was the first company to do so. Simply using medical models in educational settings would have less stringent regulations. Regulators in the EU and the US continue to support a dialog with stakeholders to determine appropriate guidance for safe and effective use of 3D printing in a point-of-care setting.

3D Systems, Synopsys, and Coreline Soft are other software manufacturer with FDA 510(k) clearance for its software to be used to aid clinicians in. 3D printing diagnostic patient-specific anatomic models.

Lead image source: 3D printed medical models by Stratasys, except for the pink heart model lower center, which is from Henkel/Loctite elastomeric red resin.

License: The text of "3D Printed Medical Models – State of the Art" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.