If 2021 was a test of how well and how fast you could pivot, 2022 will challenge you to deliver. Did you hunker down and wait for the pandemic to finally dissipate or did you throw yourself into R&D, accelerate growth, and invest?

Clearly, the later turned out to be the better course. Successful companies within the additive manufacturing industry spent 2021 perfecting new machines and materials to take advantage of the momentum in adoption. Companies that use 3D printing accelerated their plans to incorporate AM into their processes and workflows because it presented a solution to pandemic-related business issues, such as clogged supply chains and labor shortages.

For a deeper look at what to expect in 2022, we turned to our own All3DP Editorial Advisory Board of industry leaders for insight and context.

From a greater focus on volume manufacturing, software, and sustainability to more reliable and interoperable products to an anticipated spike in adoption in the automotive sector, our experts detail the what they see coming to additive manufacturing.

Pandemic-inspired AM adoption, will it last?

The ongoing pandemic highlighted supply chain vulnerabilities that manufacturers and businesses didn’t realize they had – or didn’t have a pressing reason to fix. Certainly, the AM industry sought to position 3D printing as a fix, but did it go far enough and is it sustainable?

“Significant supply chain issues have just begun opening real doors for additive, forcing executives to see the power of the technology to address their issues, from fast prototyping to quick turnaround tooling to end-use parts,” says Pat Carey, senior VP of strategic growth at Stratasys. “In many cases, companies adopted some limited additive, but had a hard time making significant changes to established processes. Now, however, they have no choice, and additive has been proven effective, so we will continue to see growth accelerated for years to come.”

Even if additive manufacturing was a quick fix to a supply problem for some, it is not likely to be abandoned post-pandemic. The reason is due not only to the capital investment, but the permanent change AM sparked in company processes and workflows.

“An analogy I think of is Zoom,” notes Douglas Krone, CEO of Dynamism, a global printer and material reseller. “Multi-party video conferencing has been available for decades and Zoom is not a substantially new experience. But Zoom is now a permanent feature of the workplace, alongside in-person meetings. In 3D printing, after the pandemic, AM for strategic planning, faster innovation, better manufacturing is now a permanent feature of the manufacturing economy.”

For businesses that use 3D printing, the pandemic exemplified the type of rapid-pivot situation that additive manufacturing was made for. In the case of Raise3D, “the pandemic mostly validated the market approach we’ve had since 2018, which focuses on flexible manufacturing,” notes Raise3D‘s VP of Strategy, Partnerships & International Business Development, Diogo Quental.

Although the pandemic may go away, disruption, whether political, societal, or environmental will not.

“There have been many COVID-related issues that focused attention on AM as a solution for disrupted supply chains, and that’s definitely great for the AM industry,” notes Sonja Rasch, sales director and an account manager for additive manufacturing at Materialise. “But there is still a lot work to do to manage expectations and find the right AM business cases.”

Simply using AM as a convenient substation to a sudden manufacturing set-back isn’t going to grow adoption in the long run, notes Rasch. Instead “thinking additively” and finding new and suitable applications is still the main goal.

Will 2022 deliver on the promise of 3D printing for production manufacturing?

There was no shortage of new 3D printers in 2021 that boasted their ability to produce more parts faster, but is the market buying?

“AM can certainly be helpful when parts need to be done fast,” notes Matthias Schmidt-Lehr, managing partner of the consultancy Ampower. “However, AM does not have the capacity and capability to replace a critical amount of manufacturing volume that currently has shortages.” In other words, AM for production is still a tough sell. Yet, there have certainly been successes.

We’ve seen cases in both polymer and metal where AM solved critical supply chain issues replacing casting or injection molded parts, especially for industries that are more flexible and have less high-end requirements for parts, notes Schmidt-Lehr.

The focus on scaling additive manufacturing for production greatly accelerated in 2021, but hardware has greatly outpaced the software, which needs to change, says Kristin Mulherin, head of market development at Dyndrite, an AM software company. “Looking towards 2022, the focus will transition to the development of AM workflow and production software tools, which is necessary to break the barriers of adopting AM as a mainstream manufacturing solution.”

Production may be the inevitable future of additive manufacturing, but it’s a long-term evolution, says Jos Burger, former CEO of Ultimaker, now board member at Ultimaker and recently also joined the board of 3YourMind. “Currently, the broader industry’s focus is multi-faceted covering prototyping, tooling, spare parts, low-volume, although high-volume production will definitively take more time.”

Which 2021 trends will expand most in 2022?

Alongside the pursuit of production, printer manufacturers and the companies that print, focused on sustainability, speed, and industry-specific software solutions.

“The focus on sustainability in additive manufacturing is a major trend that will accelerate because AM is typically used by companies that have large public exposure,” notes Schmidt-Lehr. The larger corporations that have adopted AM, from Ford and BMW to Boeing and Caterpillar, have enterprise-wide, long-term sustainability initiatives that include 3D printing technology for reducing the use and waste of raw material and also, often, for recycling. “Not everywhere and for every application, but in the right combination of application, material and technology, AM can contribute to sustainability,” he adds.

Additive manufacturing (almost always) is local manufacturing and this focus on local production is a pillar of sustainability that will only grow as AM adoption grows, notes Burger.

Wider consumers trends, from more recycled products to more sustainable manufacturing, are finding their way into 3D printing. Krone reports his customers are asking for cardboard spools and less packaging, and the market is responding. There has also been a resurgence in 3D printers that can print with pellets and shredded recycled plastics.

After sustainability, All3DP’s editorial board said AM software became a major focus of 2021 that will only expand in 2022.

“2021 was the year we all realized we need software connectivity and a software integration strategy,” notes Carey. “And with all the money back in the 3DP industry by way of investment, we’ll see rapid software innovation.”

AM specific software solutions that streamline workflows, integrate with existing enterprise solutions, and position 3D printing alongside traditional manufacturing equipment are poised to take center stage next year.

Which 2021 innovations and breakthroughs will prove most important in 2022?

We at All3DP had no shortage of new 3D printing technologies, new materials, new software, and new applications to write about in 2021, but some will have strong and lasting effects on the industry while others will fail to thrive.

One innovation in metal 3D printing that AMPower’s Schmidt-Lehr is most excited about is the new SLM technology by Seurat that illuminates an entire print bed layer at once. “Although this milestone won’t lead to significant news in 2022, it shows that laser powder bed technology has not yet reached its limits in terms of productivity, and this by itself is a major news.”

In the on-demand additive manufacturing arena, Rasch at Materialize says the certification of 3D printed, fire-resistant PA for aerospace was one breakthrough of 2021 that, next year, will no doubt lead to increased applications and use cases.

Although not entirely innovative, but a change nonetheless, the surging number of high-temperature FDM printers capable of producing reliable, high-quality parts in polymers, such as PEEK and Ultem, are breaking down barriers to the use of industrial polymers in a wide range of industries.

This will push polymer makers to improve their products, says Brian Alexander, global AM product and business development manager at Solvay Specialty Polymers.

Demand for new materials will also permeate the business FDM sector as growth is driven by consumers with a specific solution in mind as their end goal of reason for adoption, says Dave Gaylord, VP of products and technology at global reseller MatterHackers. “That solution, which is often technical and final-product oriented, is not dependent on software or hardware, but instead material properties guided by a technical data sheet. Our material catalog is going wider to achieve success in new verticals as well as deeper to ensure customers continue to have more value per application.”

Another material-related area of growth that will spur more significant developments in 2022 is metal FDM. “There are many advantages when compared to other metal AM technologies, and so, this can contribute to a new boost in AM adoption,” notes Quental, whose company recently launched a metal FDM solution.

Which industry segments will grow their adoption most in 2022?

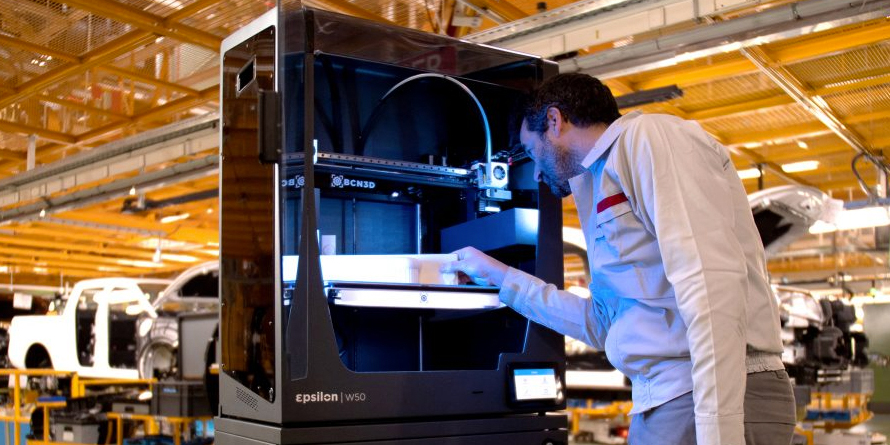

From fashion to aerospace to healthcare, additive manufacturing touches every industry. Interesting, most of our editorial board singled out the automotive industry as the sector that will grow its adoption and use of additive manufacturing the most in 2022.

“We expect strong growth in automative because it’s a highly competitive industry with high innovation that needs to keep looking for the best solutions,” notes Quental. “AM adds a lot of value.”

Schmidt-Lehr, whose work focuses mainly on metal AM, also believes the energy industry and aviation will experience strong, continuous growth in the next few years because both have significant business cases and applications that can disrupt their current practices.

Carey at Stratasys puts medical and dental at the top of the list – followed by automotive. Alexander at Solvay says, when it comes to high-performance polymer use, the energy sector, will experience growth as demand grows for AM in lithium battery and fuel cell production.

Sylvia Monsheimer, head of market segment N3D, high performance polymers at Evonik notes that construction may also be a strong industry for additive manufacturing as demand grows for rebuilding after climate-change induced weather catastrophes that threaten housing supplies worldwide.

What does the industry need most to grow in 2022?

Two divergent forces are currently in play in the AM industry and 2022 may define which one will dominate.

First, is the move to control the ecosystem, where printer manufacturers are offering integrated solutions for software, materials, printers, and post-processing to streamline the workflow for easier adoption by businesses.

On the other hand, there’s a growing demand for interoperability between sometimes competing systems. For example, software that manages AM printing across a fleet of different technologies while integrating with an organization’s larger software applications. Both approaches have the goal of simplifying industrial additive manufacturing.

Although an ecosystem approach, such as Ultimaker’s may appeal to small business, OEM’s don’t like to be bound to a suite offerings, says Monsheimer.

Carey says collaboration is what the AM industry needs more to grow: “We need to develop some standards, and integrate printers and post-processing better.”

Likewise, growth through collaboration on a common target and application is what Alexander expects to see in 2022. “In the past, everyone tried to control the ecosystem by using closed systems, now people are beginning to realize this will not work, everyone needs to know their position on the value chain and share expertise to make things work. Working in silos will not get the most from AM,” he says.

Yet, alongside collaborations, we’ll begin to see even more segmentation and specialization, according to Schmidt-Lehr. Medical and dental 3D printing has long been its own niche in additive manufacturing, but as the industry grows and more companies enter the market, we’ll begin to see more segmentation where manufacturers will focus on certain industries, applications, or even alloys, and will offer a very specific supply chain, says Schmidt-Lehr.

With that said, the biggest hurdle to mainstream adoption, according to Mulherin, is the mental hurdles engineers and designers need to jump to begin thinking about their parts and assemblies in a different way. “As so many people have said before, if you can produce a part as-is using traditional technology, then do it. For additive manufacturing to grow, the people using the technology need to be taught how to think differently and apply that to creating innovative designs that cannot be produced any other way.”

While companies and engineers may move toward optimizing their use of additive manufacturing, there’s still a hurdle for newcomers to the industry. “Seems like there is still a lot of muddy water for someone new to the space to sift through,” says Gaylord, “and the industry could use a more clear and consolidated message, in general to reach a broader audience.”

What type of new products will we see in 2022?

Rasch says the mantra for products in 2022 will be “reliable, traceable, scalable,” while Quental says we’ll see faster machines as technology evolves, but they’ll also be more expensive, production-ready, and optimized for specific applications.

Burger agrees that reliability will be the buzzword for 2022 in the hardware realm, but we’ll also see more AM specific software solutions that satisfy our craving for collaboration.

Krone believes, among his business customers, we’ll see more demand for advanced materials, repeatability, and speed. “Most of the products we see in development now are at a higher price point ($10,000 and up), so machine cost is not coming down, but, critically, part cost is.

Our 2021 predictions were on the mark!

No one wants to hear “I told you so”, but in this instance it’s a good thing. Our editorial board predictions a year ago for 2021 were mostly spot on. You can reminisce at the link below.

Do you have projections for 2022? Please share in our comments section below.

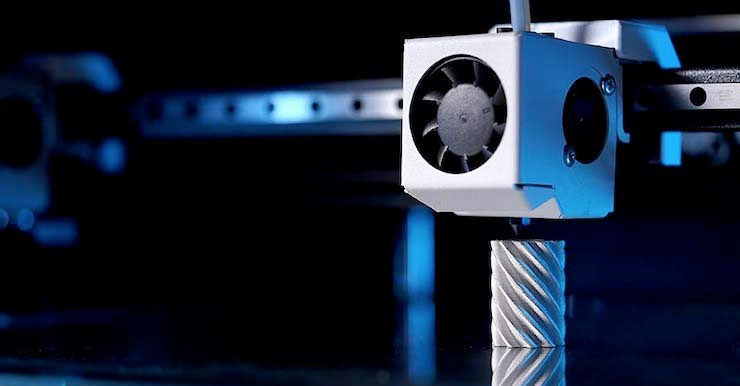

Lead image source: Raise3D

License: The text of "2022 Additive Manufacturing Outlook: Industry Leaders on the Year Ahead" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.