Volkswagen Autoeuropa is using 3D printing to bring down costs and revolutionize its workflow. The production plant now produces its own tools on-site.

In another success story of how 3D printing can pay dividends for business from localized production, we have caught wind of the news that Volkswagen’s Portuguese plant, Volkswagen Autoeuropa, is embracing additive manufacturing as an aid for its production line staff. The facility has a yearly output of around 100,000 cars, primarily the Scirocco and Sharan model lines.

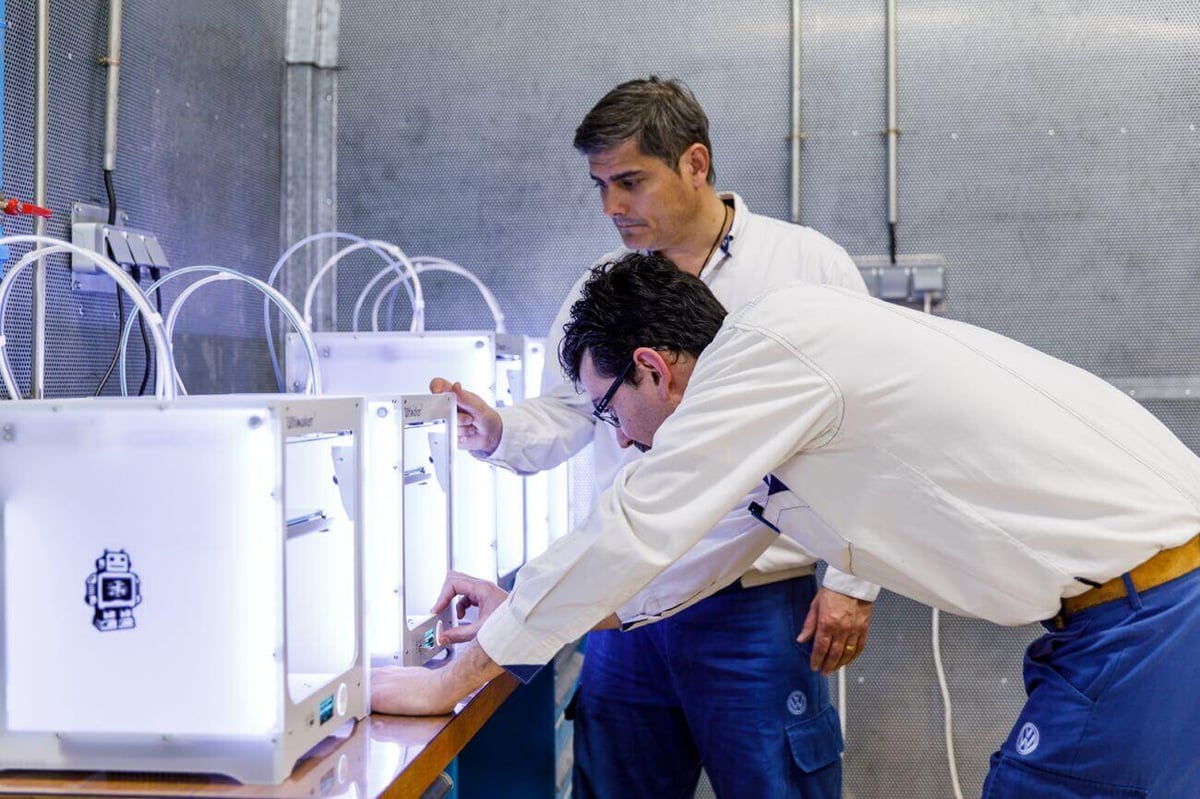

Now, the facility is using 3D printing to quickly and efficiently develop aids for manufacturing. These tools are used every day for car assembly lines, and thanks to 3D printing the company can now rapidly acquire new ones onsite. This autonomy reduces the need for external suppliers, and in turn reduces time and monetary cost since tool acquisition is localized.

The seven Ultimaker 3D printers the facility uses produce around 93% of the required tools. Previously, suppliers would take around three weeks to create the parts needed by Volkswagen Autoeuropa. Now, the same tools need mere hours.

3D Printing Pays for Itself at Volkswagen Autoeuropa

By using 3D printing, the company was able to save 91% in tool development costs. Their development time also saw a reduction of 95% too.

Luis Pascoa, Pilot Plant Manager at Volkswagen Autoeuropa explains: “Just by printing a handful of tools we can get back the initial investment.”. In fact, the investment cost of the 3D printers came back in just two months.

In 2016 the facility was able to save €150,000. The 2017 figures may rise to a whopping €250,000.

The facility can now print a tool overnight, ready for assembly line testing the next day. And better still, as is most often the case with 3D printing, iterations and design evolution can happen easily and cheaply.

If the tool is not quite up to task, the line operators can offer useful feedback. After trial and error, the exact tool can be ready to go. Complex parts and amendments are quick and easy to print.

Speaking of the benefits of 3D printing in the factory, Luis Pascoa adds: “If you consider the entire automotive industry, the potential is huge!”. Quite right.

Source: Ultimaker Blog

License: The text of "Volkswagen Autoeuropa Makes Massive Savings Using 3D Printing" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.