The world of 3D printing is a fascinating place, full of wonders. And if you spend any amount of time here, you’ll quickly realize there are many different tribes, each following their own path and their own philosophy.

First and foremost there are those tribes aligned along the technique of fabrication, whether it be fused-deposition modeling, stereolithography, or selective-laser sintering. Then there is the Open Source tribe, espousing the freedom to choose, develop and tinker with your 3D printer without artificial constraints on hardware and software.

And then there is the Proprietary tribe, whose argument is that by controlling the hardware, software and materials ecosystem from end-to-end, they can guarantee a better experience for their customers. The Polish 3D printer manufacturer Zortrax sits squarely in this latter category.

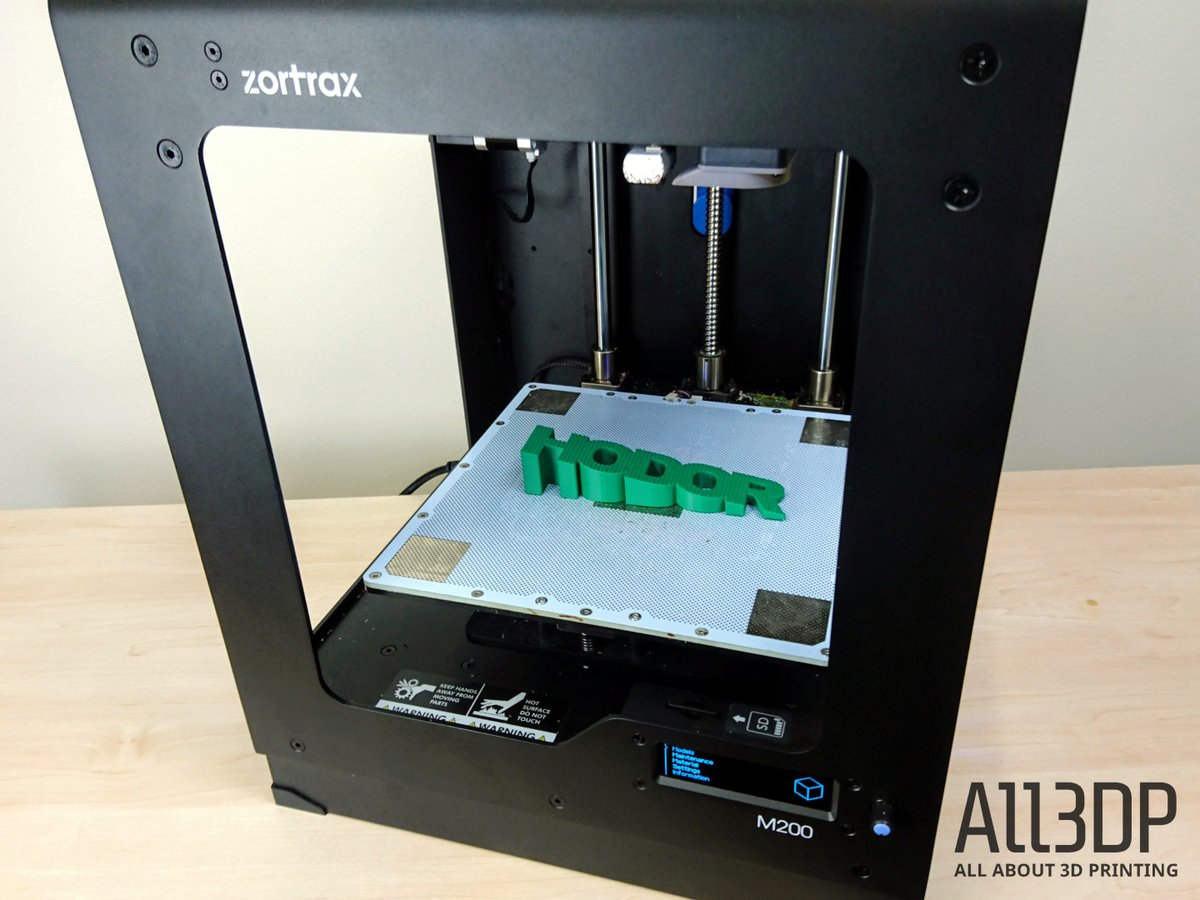

Their flagship machine, the Zortrax M200, is a sturdy and reliable 3D printer that’s pretty much a closed box. It’s accompanied by a growing library of proprietary filaments that are optimized for their 3D printer. And to prep models for 3D printing, you have to use their Z-Suite software.

Is this a problem? Not necessarily. To some folks, the only thing that matters are the end results. And in those terms, the Zortrax M200 is very impressive. It has a set of key features that make it a simple machine to operate and can deliver consistent results.

More recently, some fresh changes to the software mean that it’s now capable of printing with third-party filaments. With this in mind, we put together a fresh Zortrax M200 review to see whether it performs so dependably when it steps outside its walled garden.

Pros

- Reliable, Consistent Results

- Zortrax M200 has an Iconic Design

- Print Bed Calibration is Simple

- Firmware Update Process is Painless

- Sleep Mode Saves Energy

- Zortrax M200 is Idiot-Proof

- Current Pricing is Good Value

- Now Compatible with Third Party Filament

- New Software Features

Cons

- Hardware is Aging

- Software Slicer is Slow

- Zortrax M200 Direct Drive is Weak

- Supplied Spool Holder Too Small

- Traces of Charcoal Lumps in Prints

- Zortrax M200 puts a Raft on Everything

- ABS is Prone to Cracking

- Mild Odors

- Stringy Infill

Verdict

So many caveats to consider with the Zortrax M200 3D printer. So many!

Firstly, this is a proprietary device that locks the user into its ecosystem. But the printing results are well above average.

Secondly, the Zortrax M200 has a perforated bed that puts a raft on everything by default. But that makes the business of printing with ABS hugely better.

Thirdly, the 2013 hardware design is looking pretty tired compared to more modern offerings. But the Zortrax M200 is holding up remarkably well thanks to new features added in the software.

Sadly, we cannot say that being able to print with third-party filaments was a significant improvement over their own material formulations. But it’s still nice to know the flexibility is there.

And the slicing software Z-Suite is slow and cumbersome. Then again, it’s pretty good at breaking down each stage of the process for absolute beginners.

Ultimately, the Zortrax M200 still remains what it has always been. The absolute very best desktop 3D printer for working with ABS filaments — especially if they are the company’s own. But it’s not so great printing with PLA, exotics, or anything else that doesn’t require a perforated bed.

Put another way, the Zortrax M200 is a 3D printer workhorse geared towards a specific material. Using it beyond this narrow scope is not going to be the best use of your time. It’s a case of knowing when to use the right tool for the right job.

So for those users who need to work with ABS or ABS composite materials, where they don’t want to compromise on properties like strength, durability and impact resistance, the Zortrax M200 3D printer is the best choice.

The Looooong Read

The Zortrax M200 first burst onto the desktop 3D printing world via the crowdfunding platform Kickstarter. The campaign was launched in 2013, where 144 backers pledged $179,471 towards the project.

The money raised wasn’t astronomical, not compared to the sums raised by modern 3D printers on Kickstarter, but it was comfortably over their initial goal of $100,000. And the pitch was strong and simple.

“Just Plug & Print! We make it awesome.”

Five years later, Zortrax is among the front-line of desktop 3D printer manufacturers. Behind the flagship Zortrax M200, a line of products has grown to encompass materials, software, and two more 3D printers; the smaller, dual extrusion Zortrax Inventure, and the bigger volume Zortrax M300.

Revisiting the Zortrax M200 3D printer, it’s startling to consider that this hardware platform is five years old. That’s an eternity in technological terms.

True, like every other FDM printer, it’s leveraging the principles of elapsed patents that were filed more than 30 years ago. But in the nearer term, the Zortrax M200 has stayed relevant through a series of unique features and software updates which open up new capabilities.

Design and Features

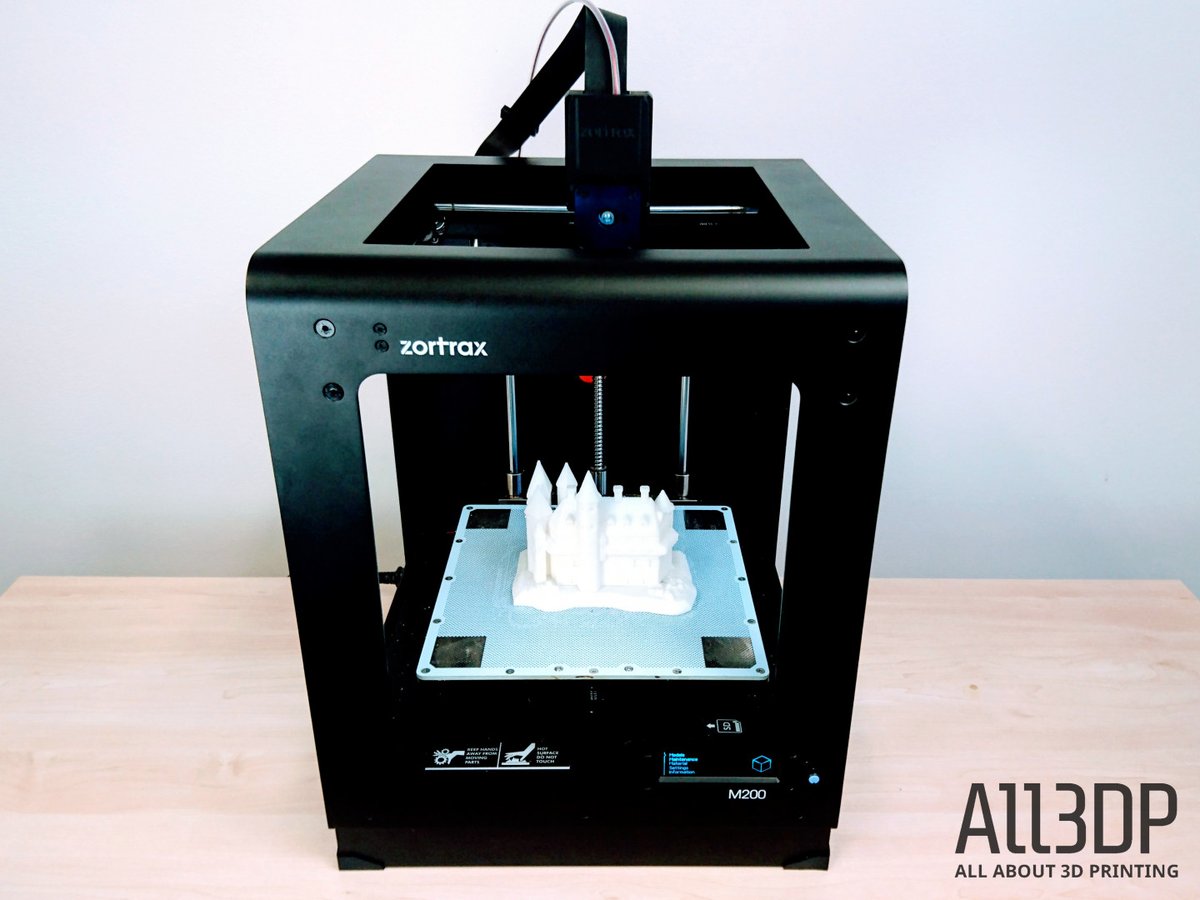

Perhaps it’s an exaggeration, but we regard the design of the Zortrax M200 3D printer as rather iconic. It hasn’t been copied by many others, and stands distinct from a sea of Prusa and MakerBot clones.

The Zortrax M200 has a black powder coated metal frame with a direct drive extruder, a perforated heated bed, and onboard LCD controls.

It’s a fused-deposition modeling 3D printer that pushes molten thermoplastic filament through a heated nozzle, and builds a solid object by depositing one thin layer of plastic after the other.

The design is a Cartesian frame, where the print head moves on the X and Y axis and the print bed moves on the Z axis.

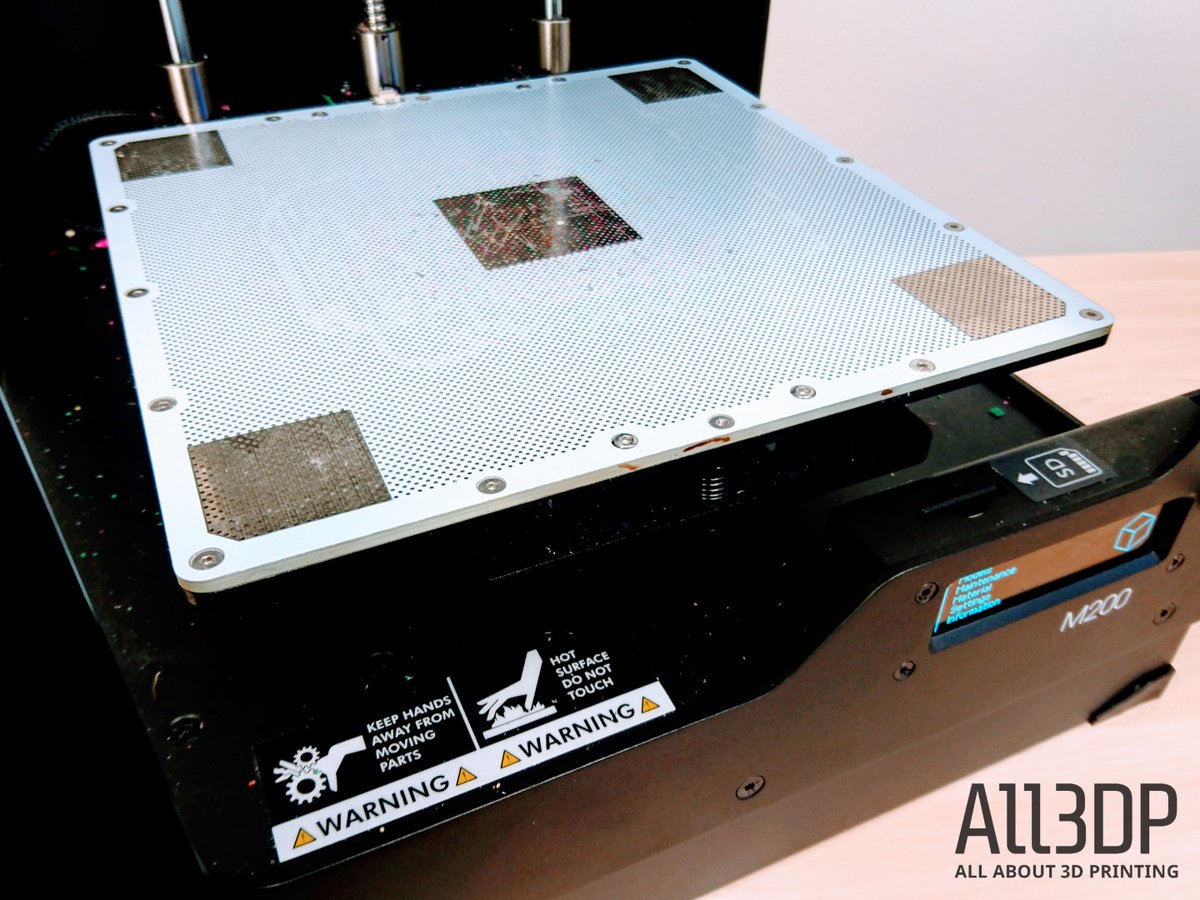

The perforated heated bed is the standout feature of the Zortrax M200; printing with ABS is notoriously tricky in terms of first layer adhesion. This printer gets around that by laying down a fat raft of molten plastic that clings to the perforations, and then commences building the object on top.

It works admirably, except when the print is finished and it takes some effort to prise the model off the raft without damaging it. We would prefer it if the Zortrax M200 had a removable bed, like the Tiertime UP mini 2, to make the process a little bit easier.

Also worth nothing is that having a perforated bed and raft is wholly pointless if printing with a more forgiving material like PLA.

Finally, the feature that we absolutely love about the Zortrax M200 3D printer (and which we believe is still unique) is the sleep mode. As in, when the print job is finished, the machine will put itself into a low-power slumber mode.

This is absolutely vital not just in terms of energy savings, but health and safety as well. Raise your hands if you’ve ever started a print job so large that you had to leave the printer running overnight…

Specifications

- Printer type: FDM

- Material: ABS, HIPS, ULTRAT

- Build volume: 200 x 200 x 185 mm

- Minimum Layer Height: 25 microns

- Maximum Layer Height: 400 microns

- Extruder Head: 1

- XY Precision: 1.5 microns

- Printing Speed: 100 mm/s

- Open Source: No

- Third Party Material: Yes

- Heated Platform: Yes

- Filament Diameter: 1.75

- On-Printer Controls: Yes

- Connectivity: USB, SD card

Setup

Setting up the Zortrax M200 3D printer is effortless. You unbox the unit, plug it in and switch it on. There’s also a little starter kit with things like pliers, spatula and a knife for post-processing.

Calibration of the print-bed is guided from the LCD control panel, where a probe checks four areas of the bed and then prompts you to make adjustments by turning the respective knob. It’s much easier to calibrate a Zortrax M200 than, for example, an Ultimaker 2 series machine.

The bundled spool holder is 3D printed — only one of a handful of components on the unit that are — and slots onto the back of the unit.

It’s rather puny, designed to hold rather narrow spools of filament e.g. the Zortrax range of filaments. One of the first things you’ll want to do is fabricate yourself a bigger one.

Another key setup stage is checking you have the most current firmware. The latest versions are detailed under the Zortrax M200 downloads page.

Updating firmware is as simple as loading it onto an SD card and navigating to the file on the control panel; the Zortrax M200 instantly recognizes it and knows what to do. It’s a painless process, and one that we appreciate being able to do without tethering the unit to a PC.

Speaking of which, if you’re a Linux user, then you’re out of luck. The Z-Suite software — essential to prep files for printing on the Zortrax M200 — is only compatible with Mac or PC.

It’s a logical decision by Zortrax, we suppose; a user of open source software is highly unlikely to use a proprietary 3D printer. But the omission is noticeable.

Filament

Bundled together with our review unit of the Zortrax M200 3D printer, we received four spools of filament; two spools of the Z-ABS and two spools of Z-ULTRAT. Both of these filaments are made in-house by Zortrax.

According to their spec sheets, the composition of the Z-ABS is near pure Acrylonitrile-Butadiene-Styrene, with additional ingredients for stabilization and lubrication.

This is the most basic material available for the Zortrax M200, with applicable use-cases like concept models, gadgets and figurines, display models, or models with moderate functional and testing properties. It’s available direct from the company in 800g spools for around $30.

Stepping up the ladder, Z-ULTRAT is an ABS composite material, with a smidgen of polycarbonate added for enhanced strength and durability.

This is recommended as the defacto standard material for the Zortrax M200, suitable for functional prototypes, end-use parts, mechanical parts, or elements required to be durable and stable over time. It’s a bit more expensive, however, where an 800g spool sells for roughly $40.

More recently, the company opened up the Zortrax M200 for compatibility with third-party materials. For the purposes of our testing, we picked up a standard spool of ABS from Rigid Ink.

It’s not going to be a simple process of swapping out one filament brand for another, however. The Z-Suite Software plays a vital role as the bridge between hardware and material, as you’ll find out below.

Software

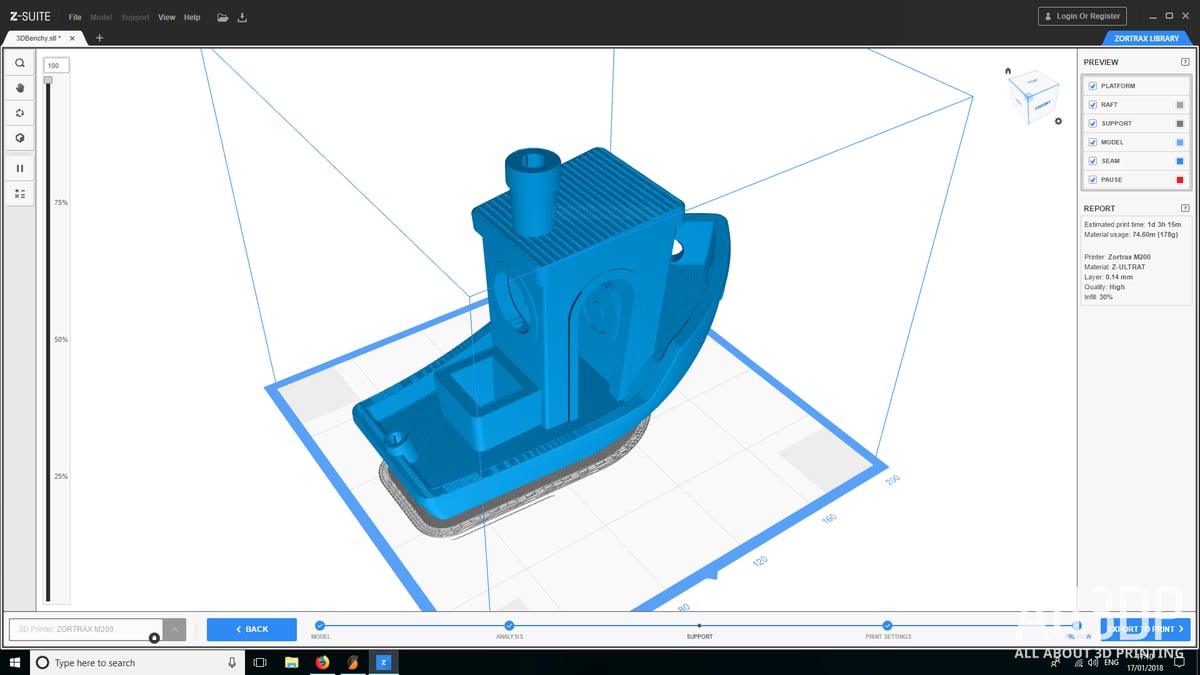

The Z-Suite software is where the benefit of proprietary filament becomes obvious. That’s because the optimal settings for the filament are preloaded into the software; you just select the material and the desired output quality and the software handles the rest. This kind of convenience is hard to dislike!

Throwing in third-party materials complicates the pudding, somewhat. Beneath an “advanced options” tab, you can input the settings like hotend temperature and bed temperature, but they often deviate from the recommended parameters provided by Z-Suite. This is where you go through a trial and error process with the printing.

Beyond the topic of filaments, using the software overall is a bit clunky. If you’re used to the whizz-bang speed of Cura or Simplify3D, then using Z-Suite is a little bit of a throwback to the bad old days of waiting forever and ever for an object to be sliced. There’s a bottleneck in the software, and no amount of RAM in your computer can sidestep it.

Preparing an object for printing on the Zortrax M200 is broken down over multiple stages; load in the model, analysis, supports, settings and preview. It’s good for absolute beginners, but frustrating if you want to go back a step or two from the preview stage. That’s because the software wipes the model you’ve just sliced, and the waiting begins anew.

Something important (and positive) about the recent software update is that you now have a greater choice of infill pattern. Previously the default was a square grid. Now you can select an additional two infill patterns — either a hexagon or octagon — for greater structural strength.

3D Printing with Proprietary Filaments

Using the proprietary filaments, we did a lot of printing with the Zortrax M200 in the ALL3DP workshop. Everyone in the office had a go using it, simply because operating the machine is so effortless.

The Z-ULTRAT is definitely the way forward for long-term use. In a shocking shade of pink, we printed a variety of objects at the default, normal quality settings of 140 microns.

First up is the standard 3DBenchy, printed not once but twice. The overall quality is very very high, except for some minor warping on the lower half of the prow. As mentioned before, removing the raft is tricky, and resulted in some damage to the bottom layer.

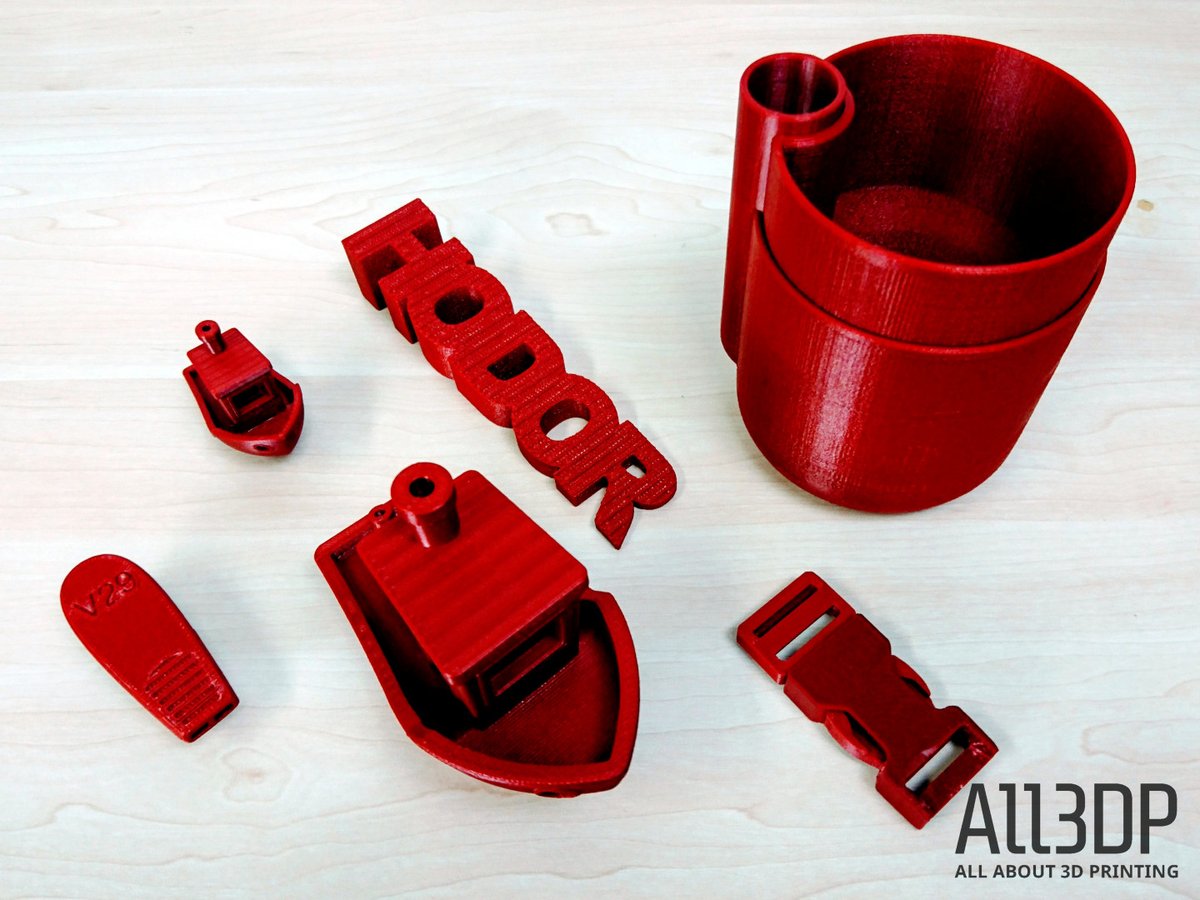

Next are a series of equally small objects; the V29 super loud whistle, a print-in-place ball bearing, and a squishy turtle toy assembled from multiple parts.

It sounds like an innocuous collection, but each further proved the capabilities of the Zortrax M200 3D printer. The whistle works as advertised, which means the chamber is printed clean. The ball bearing rotated as it should, so the mechanical accuracy is present and correct. And assembling the toy required that the disparate parts had a snug fit.

Finally, we moved onto a pair of larger objects; a self-watering planter and an acoustic amplifier for the office Amazon Echo Dot.

The planter consists of two parts, and challenges the 3D printer by requiring some steep overhangs and a watertight base. The acoustic amp tested the filament retraction of Zortrax M200, with disparate elements of the design that come together in the top layers. Both objects get a solid pass.

On the downside, bits of charcoal residue would appear at random spots in the print, whether in the infill or the outer shell. Flecks of it gather on the hotend, and seem to be deposited at random junctures. It’s annoying, and requires you to monitor the hotend and clean the Zortrax M200 regularly.

3D Printing with Third Party Filaments

Using third-party filaments on the Zortrax M200 3D printer is not such a resounding success. We still produced some decent objects, but there were bumps in the road that make it more difficult to recommend.

The first silly thing we did was try to print with flexible filaments. We theorized that, since the Zortrax M200 is technically a direct drive 3D printer, it would be capable of printing softer materials by firmly gripping and extruding the filament. Our hypothesis was totally wrong.

The flexible material got properly snarled up around the extruder, and we had to physically disassemble the print-head to remove the stuck filament. The wheel of the extruder on the Zortrax M200 is simply too small to handle this material.

Going back to standard ABS, we printed a variety of objects at the default, normal quality settings of 140 microns. The small round of objects included a 3DBenchy, a V29 whistle, and a rucksack buckle.

The larger objects were a HODOR doorstop (any Game of Thrones fans in the house?), another self-watering planter, and a giant size 3DBenchy printed at 300% scale.

The small objects made the grade. The infill looked a bit stringy, but the outer shells printed perfectly well.

But when it came to printing the larger objects we encountered a major headache with cracking. This is a problem that’s unique to ABS, in that temperature changes can cause large cracks between layers in tall objects. It happened a lot with the self-watering planter and the giant-size 3DBenchy, in particular.

Now this might not be a fair comparison between standard ABS and the Z-ULTRAT ABS composite. But it shows another reason why Zortrax belongs to the proprietary tribe. Their in-house filament is formulated with ingredients like wax and tallow to mitigate the occurrence.

Elsewhere, they sell a series of panels to fully enclose the Zortrax M200 and better regulate the printing temperature and avoid cracking. On this latter point, we would argue that the company should offer the panels by default. It goes some way towards reducing the spread of stinky odors that arise with printing with ABS, too.

Wrapping Up

Still with us so far? If there’s one thing that we should make plainly clear in our Zortrax M200 review, it’s that it is a truly great 3D printer.

The only condition is that you understand and accept the parameters of its usage; a closed loop system that asks you to exchange freedom of choice for dependable results.

The argument makes sense, to a point. There’s much that can (and does) go wrong when 3D printing with ABS material, so entrusting total control to someone else is basically outsourcing the aggravation.

It’s a curious decision to open up the Zortrax M200 3D printer to third-party filaments. Freedom of choice means you can experiment with different materials, textures and properties, more than the company can hope to keep up with by themselves.

But whilst the prospect is exciting, the reality is disappointing. If anything, the whole exercise serves to reaffirm the values of the Proprietary tribe.

So let’s move on from this little tangent and focus on what it is that the Zortrax M200 truly excels at. Load it up with a fresh spool of Z-ULTRAT and you will have a trusty partner, reliably cranking out one quality printed object after the next.

Alternatives to the Zortrax M200

For those folks not entirely sold on the Zortrax M200 3D printer, there are a couple of worthy alternatives to consider.

Don’t Miss: UP mini 2 Review – Best 3D Printer for Beginners in 2018

The Tiertime UP mini 2 is a compact desktop 3D printer that shares a key attribute with with the Zortrax M200 — the use of perforated beds to ensure that prints stick firm when laying down those critical first layers. This is perfect for printing with ABS.

It also adds some extra features the Zortrax M200 is lacking; an enclosed build chamber, a HEPA filter, and a special filament caddy to protect the material from spoiling. There’s also a “power panic” feature in case of electrical power failures and wireless connectivity.

Print quality is pretty decent, and the price is right at an RRP of around $600. Where it falls down, however, is the puny build space. The UP mini 2 is simply too small to be of practical use except to absolute beginners.

Elsewhere, a very different kind of 3D printer workhorse from the Zortrax M200 is the MakerGear M3. This is an open source 3D printer that can fabricate with most filaments you throw at it. It’s available as DIY kit, is upgradeable to dual extrusion, and has wireless connectivity.

License: The text of "Zortrax M200 Review – Best 3D Printer Workhorse of 2017" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.