This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

3-D-P, Easy as 1-2-3

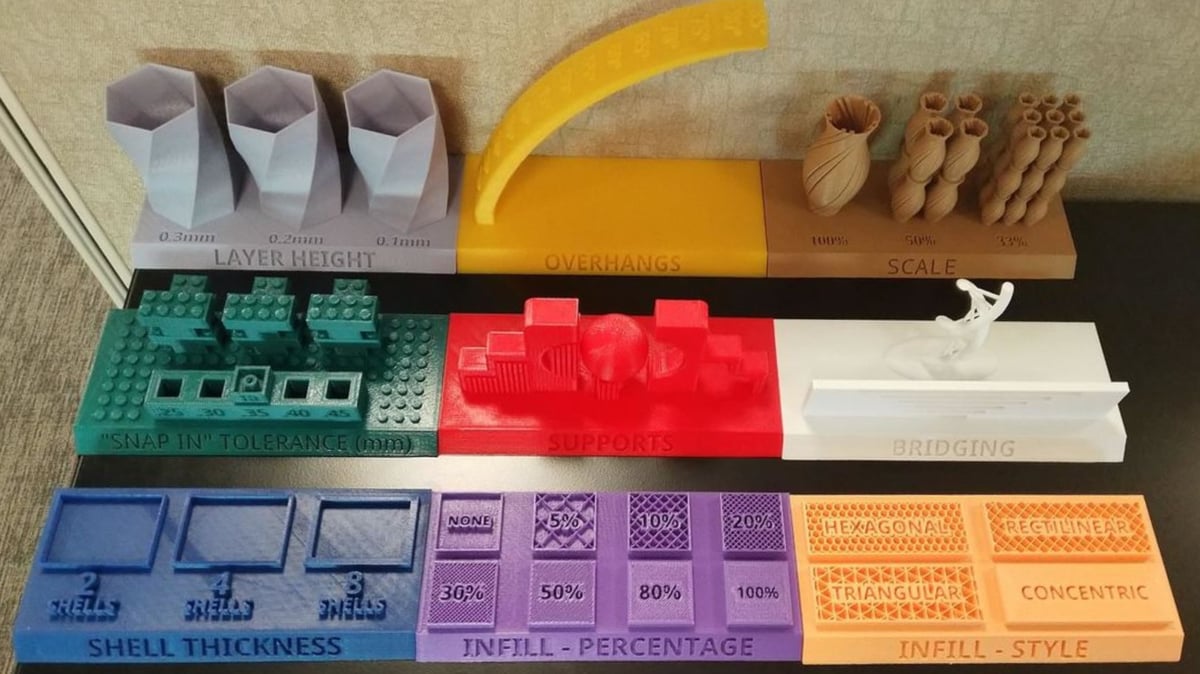

3D Printing Terminology: All Important 3D Printing Terms

The world of 3D printing is full of acronyms and unusual words. Read on to learn about common 3D printing terminology!

Advertisement

Advertisement