This article is free for you and free from outside influence. To keep things this way, we finance it through advertising, ad-free subscriptions, and shopping links. If you purchase using a shopping link, we may earn a commission. Learn more

Good to the Bone

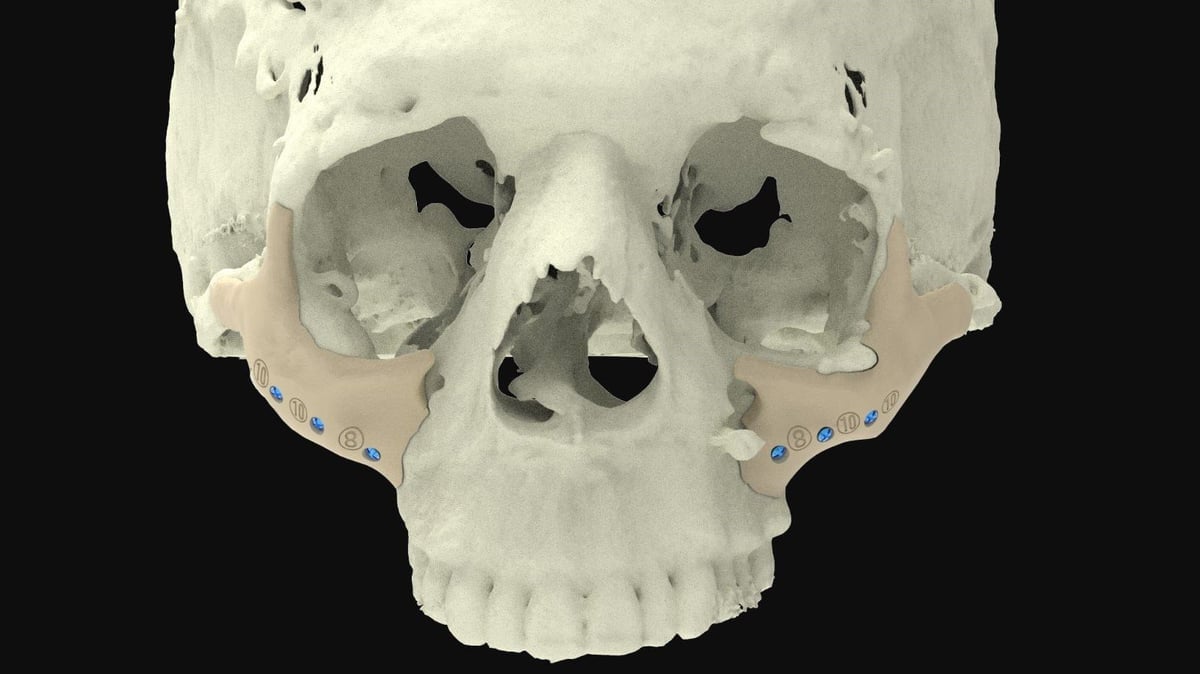

3D Printed Bones: The Most Jaw-Dropping Projects

3D printed bones are no longer a thing of the future; they're very real! Read on to learn about 3D printed bone projects in medicine today.

Advertisement

Advertisement